Etching solution, preparation method thereof and metal film processing method

An etching solution and metal film technology, applied in the field of chemical etching, can solve the problems of poor etching accuracy, side etching, and poor etching uniformity, and achieve the effects of smooth etching angle, good etching uniformity and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Mix phosphoric acid, nitric acid, acetic acid, metal corrosion inhibitor and water evenly in a certain proportion, and filter to obtain etching solution. The etching solution comprises the following components in parts by weight: 65 parts of phosphoric acid, 3 parts of nitric acid, 17.5 parts of acetic acid, 0.05 part of metal corrosion inhibitor, specifically potassium acetate, sulfonated lignin, 2-phosphonic acid A mixture of butane-1,2,4-tricarboxylic acid and mercaptobenzothiazole, 0.5 part of nonylphenol polyoxyethylene ether, 0.05 part of fatty alcohol polyoxyethylene ether sodium sulfate, and the balance is water.

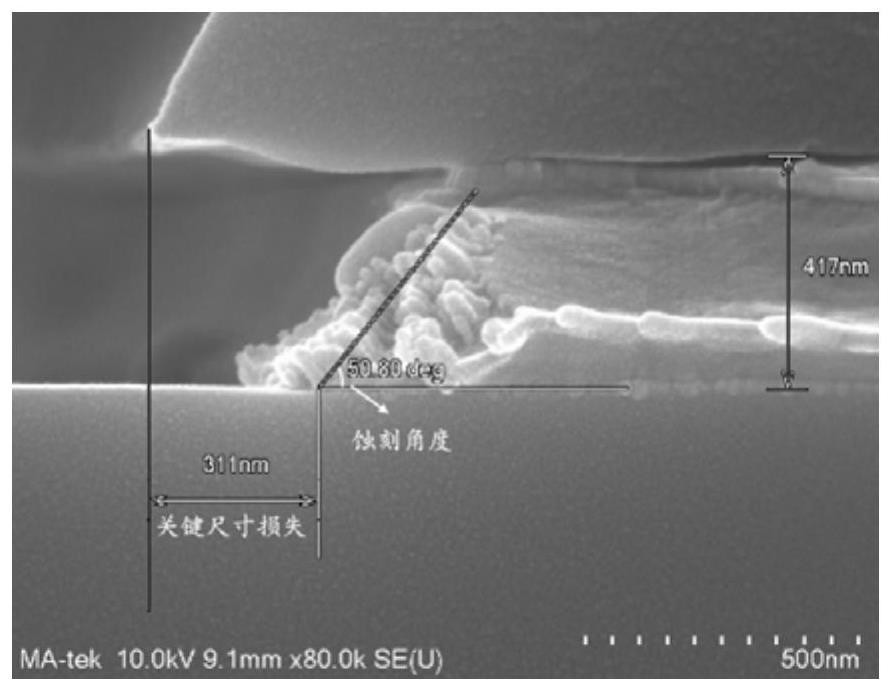

[0034] Place the glass panel covered with the molybdenum-aluminum-molybdenum laminated film in the above etching solution at 40°C for 100s, wherein the thickness of each metal film along the thickness direction is 200nm, 3800nm, 500nm respectively. The etched sample is denoted as S1.

Embodiment 2

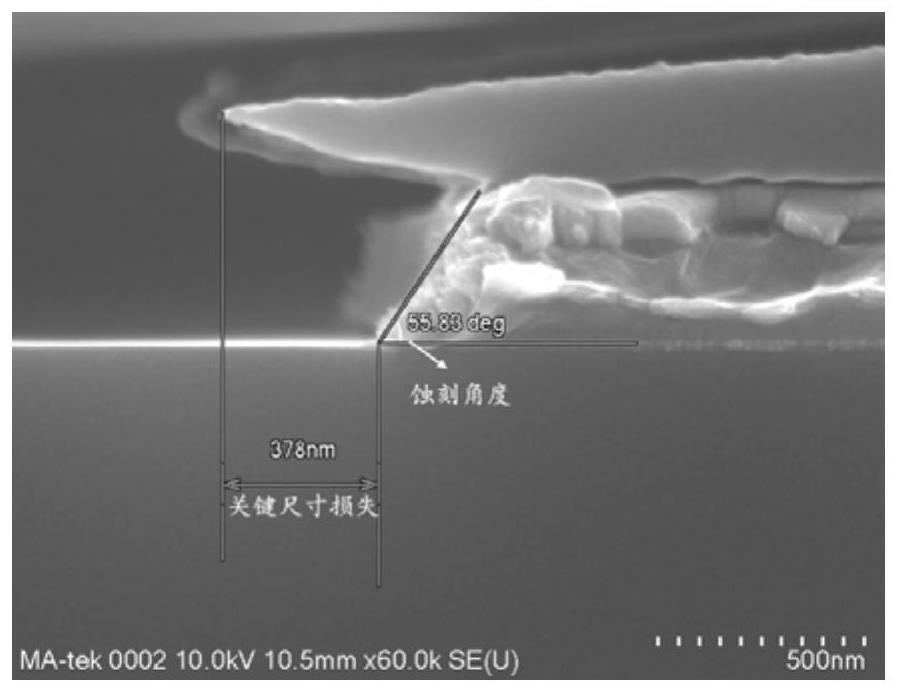

[0036] The difference between embodiment 2 and embodiment 1 is: etching solution comprises each component of following parts by weight: the phosphoric acid of 50 parts, the nitric acid of 1 part, the acetic acid of 10 parts, the potassium acetate of 0.01 part, sulfonated lignin, 2 parts -A mixture of phosphonic acid butane-1,2,4-tricarboxylic acid and mercaptobenzothiazole, 0.01 part of nonylphenol polyoxyethylene ether, 0.05 part of fatty alcohol polyoxyethylene ether sodium sulfate, and the balance is water. The etched sample is denoted as S2.

Embodiment 3

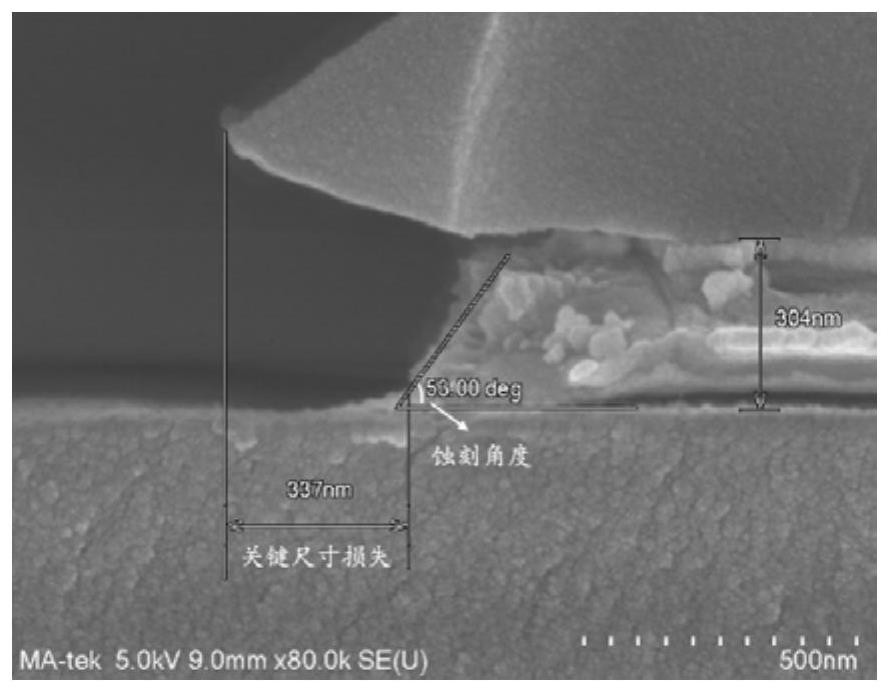

[0038] The difference between embodiment 3 and embodiment 1 is: etching solution comprises each component of following parts by weight: the phosphoric acid of 80 parts, the nitric acid of 10 parts, the acetic acid of 30 parts, the potassium acetate of 0.05 part, sulfonated lignin, 2 -A mixture of phosphonic acid butane-1,2,4-tricarboxylic acid and mercaptobenzothiazole, 0.25 parts of nonylphenol polyoxyethylene ether, 0.75 parts of fatty alcohol polyoxyethylene ether sodium sulfate, and the balance is water. The etched sample is denoted as S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com