Three-dimensional graphene/conductive polypyrrole/conductive MOF composite electrode material and preparation method thereof

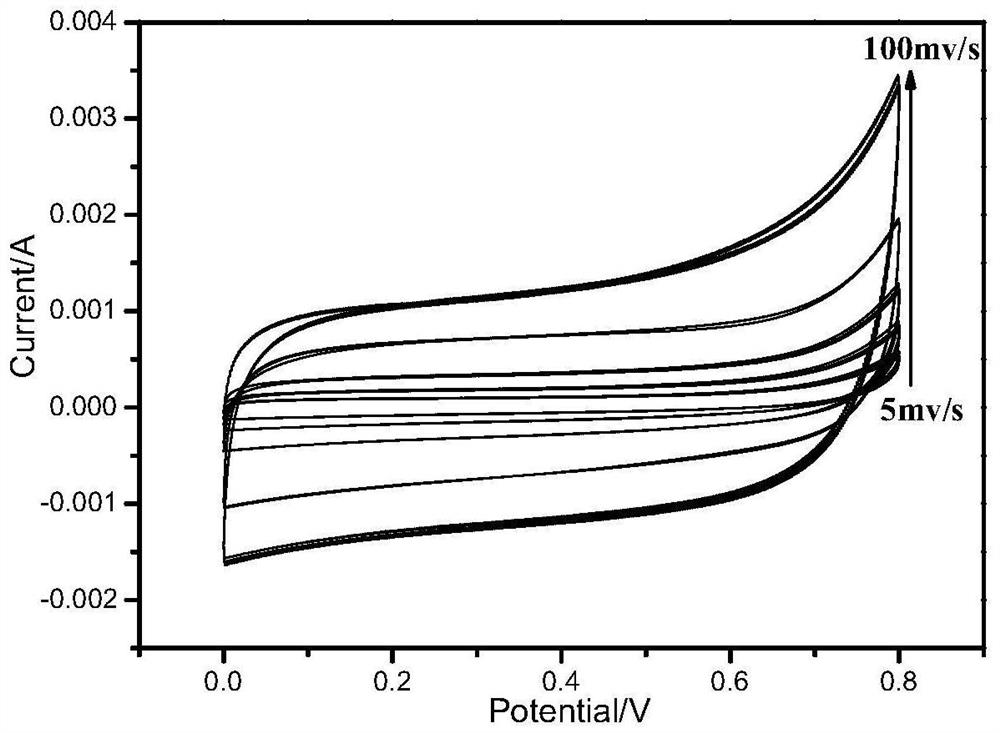

A composite electrode and graphene technology, which is applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of electrochemical performance attenuation and achieve high energy density, excellent cycle stability, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Graphene oxide was prepared by the improved Hummers method. Weigh 0.4 g of graphene oxide and dissolve it in 20 ml of distilled water, and stir evenly to obtain a graphene oxide solution.

[0025] (2) Add 1.4mL of phytic acid to the graphene oxide solution prepared in step (1), add 1.4mL of freshly steamed pyrrole monomer under full stirring, and mechanically stir for 5min until the pyrrole monomer is completely uniformly dispersed, then add 30mL ammonium persulfate solution. Stir evenly for 12 hours, wash and dry.

[0026] (3) Weigh 0.04 g of the composite material prepared in step (2), dissolve it in 20 ml of distilled water, and stir evenly.

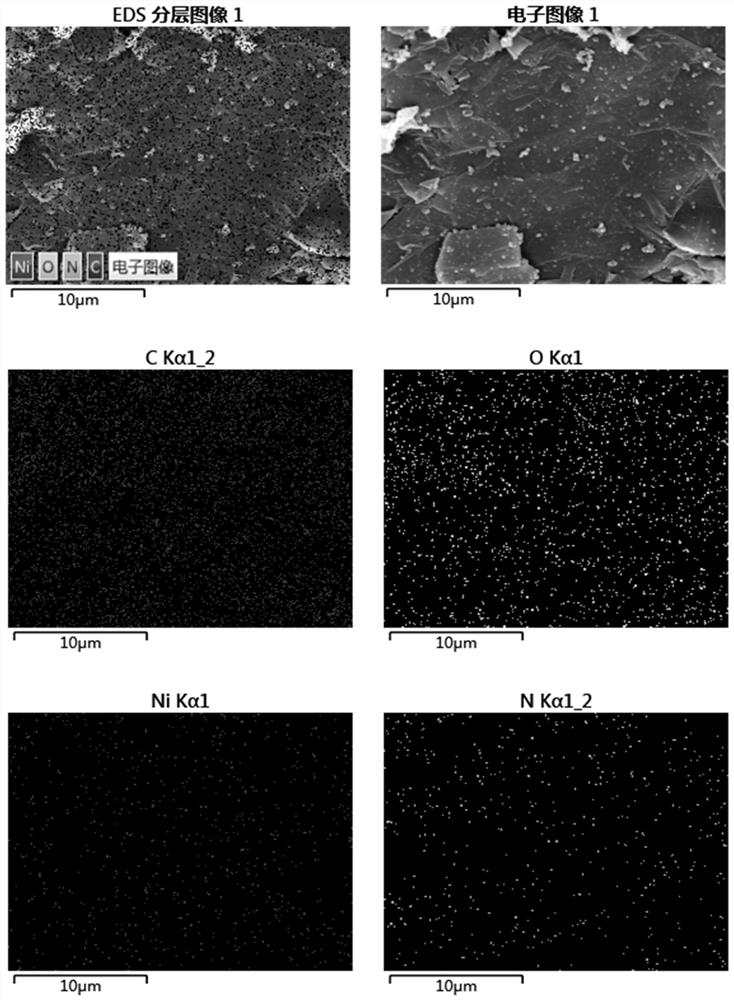

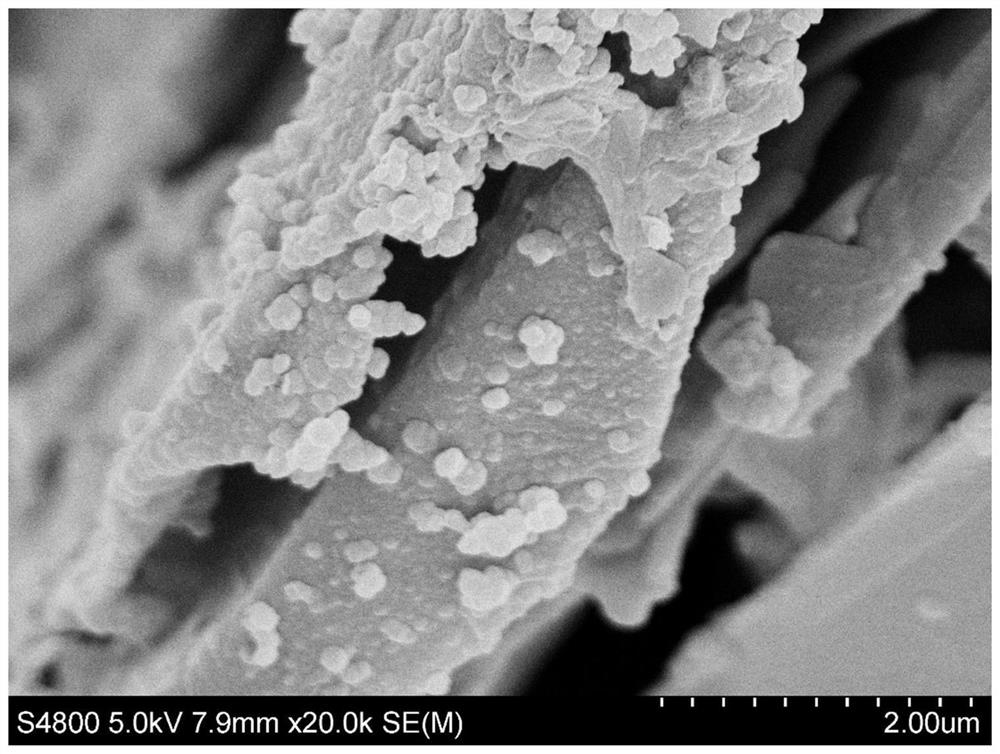

[0027] (4) Weigh 0.1mmolNi(NO 3 ) 2 6H 2 O was dissolved in 10ml of water, slowly poured into the solution prepared in step (3), and stirred for 2h. Washing, drying and drying to obtain polypyrrole@3D graphene / conductive MOF composite material.

Embodiment 2

[0029] (1) Graphene oxide was prepared by the improved Hummers method. Weigh 0.4 g of graphene oxide and dissolve it in 20 ml of distilled water, and stir evenly to obtain a graphene oxide solution.

[0030] (2) Add 2.8mL of phytic acid to the graphene oxide solution prepared in step (1), add 1.4mL of freshly steamed pyrrole monomer under full stirring, and mechanically stir for 5min until the pyrrole monomer is completely uniformly dispersed, then add 30mL ammonium persulfate solution. Stir evenly for 12 hours, wash and dry.

[0031] (3) Weigh 0.04 g of the composite material prepared in step (2), dissolve it in 20 ml of distilled water, and stir evenly.

[0032] (4) Weigh 0.1mmolNi(NO 3 ) 2 6H 2 O was dissolved in 10ml of water, slowly poured into the solution prepared in step (3), and stirred for 2h. Washing, drying and drying to obtain polypyrrole@3D graphene / conductive MOF composite material.

Embodiment 3

[0034] (1) Graphene oxide was prepared by the improved Hummers method. Weigh 0.4 g of graphene oxide and dissolve it in 20 ml of distilled water, and stir evenly to obtain a graphene oxide solution.

[0035] (2) Add 3.6mL of phytic acid to the graphene oxide solution prepared in step (1), add 1.4mL of freshly steamed pyrrole monomer under full stirring, and mechanically stir for 5min until the pyrrole monomer is completely uniformly dispersed, then add 30mL ammonium persulfate solution. Stir evenly for 12 hours, wash and dry.

[0036] (3) Weigh 0.04 g of the composite material prepared in step (2), dissolve it in 20 ml of distilled water, and stir evenly.

[0037] (4) Weigh 0.1mmolNi(NO 3 ) 2 6H 2 O was dissolved in 10ml of water, slowly poured into the solution prepared in step (3), and stirred for 2h. Washing, drying and drying to obtain polypyrrole@3D graphene / conductive MOF composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com