CCM for fuel cell membrane electrode and production method thereof

A fuel cell membrane and production method technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of precious metal particles falling off, blocking hydrogen transmission, accelerating the corrosion and dissolution of carbon carriers, etc., to improve catalytic activity and improve stirring effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A kind of CCM that is used for the membrane electrode of fuel cell, the anode catalyst that described CCM adopts is Pt / Ti 4 o 7 , where Pt is the active component, Ti 4 o 7 As a carrier, the mass fraction of Pt is 60%, and the cathode catalyst adopted by the CCM is Pt 6 co 1 mn 1 / GC, wherein the mass fraction of platinum cobalt manganese is 60%.

[0068] Carbon powder and fine Ti 4 o 7 The relevant physical properties of the powder are as follows:

[0069]

[0070]

[0071] Ti 4 o 7 The specific surface area of powder and carbon powder is similar, both are suitable as catalyst carrier. The primary particle size is similar, and both are suitable for conventional slurry dispersion and ultrasonic spraying. In a reducing environment at 80°C, Ti 4 o 7 The powder still maintains a high electrical conductivity. So in the conductivity of the anode carrier, Ti 4 o 7 The powder is comparable to carbon powder. However, in an oxidizing environment at 80°C,...

Embodiment 2

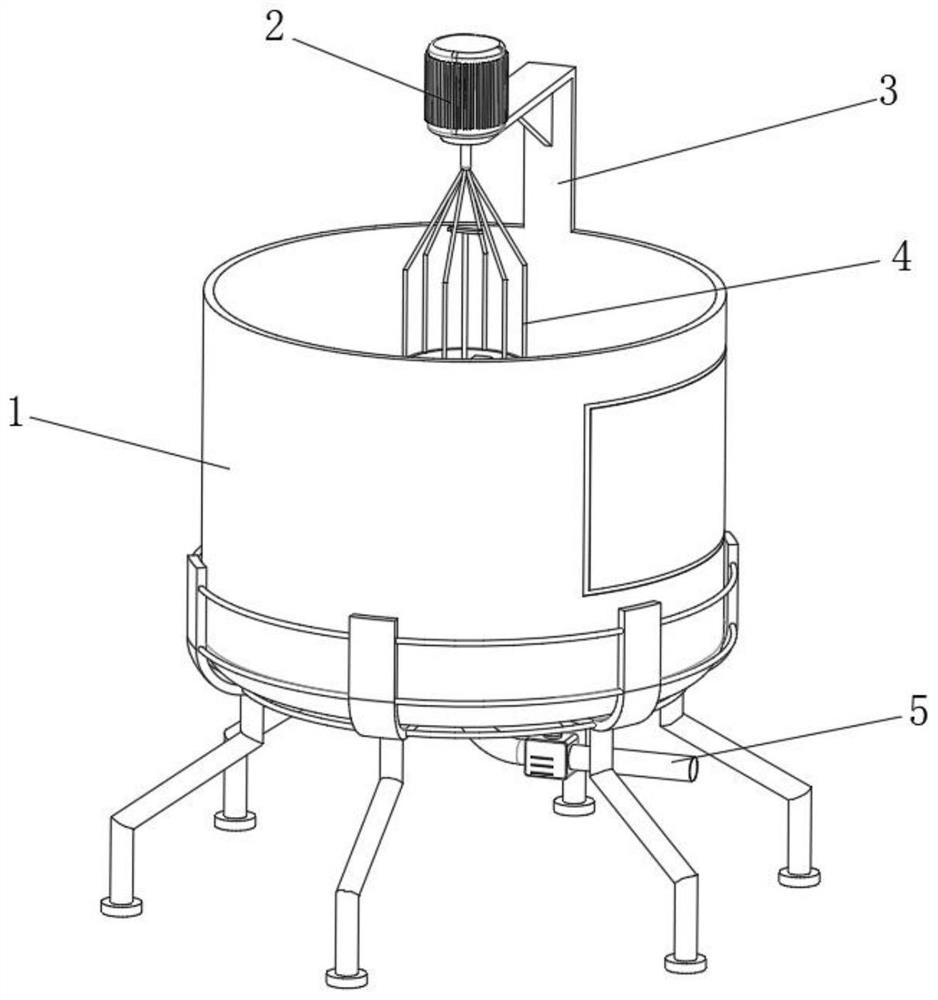

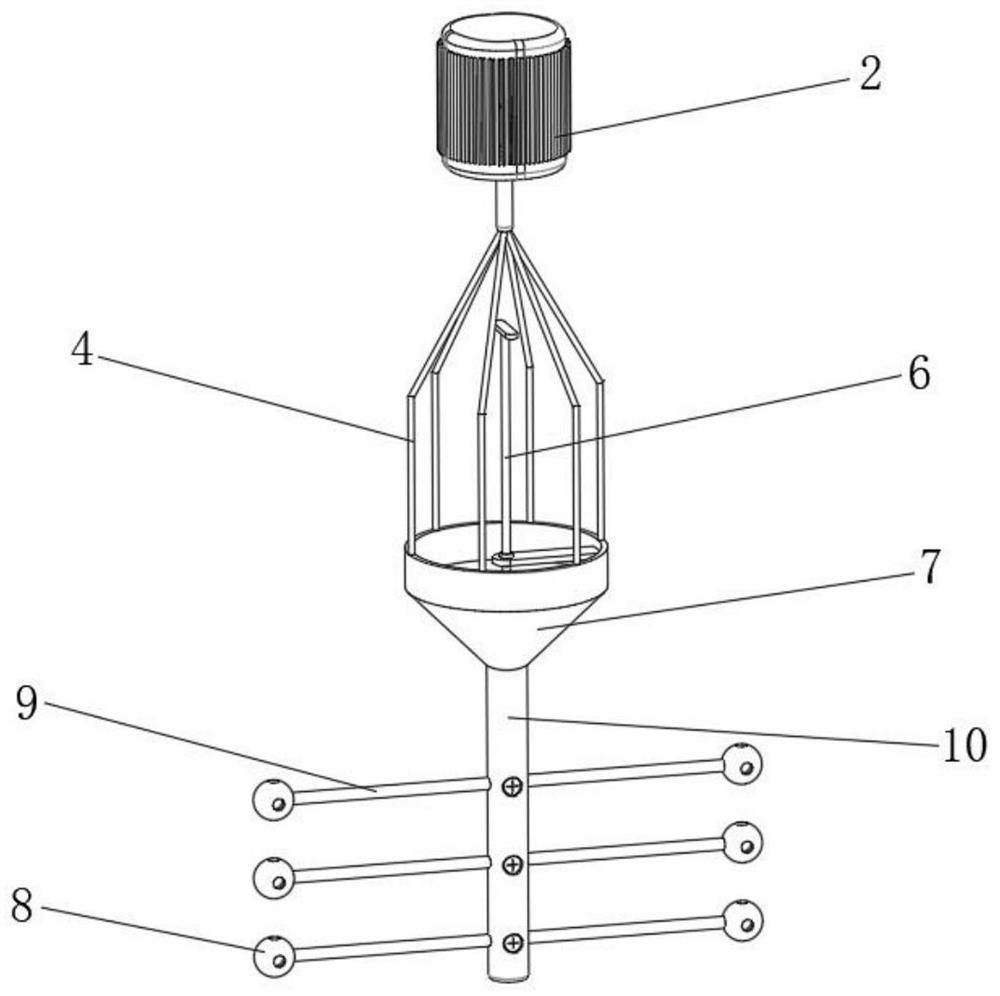

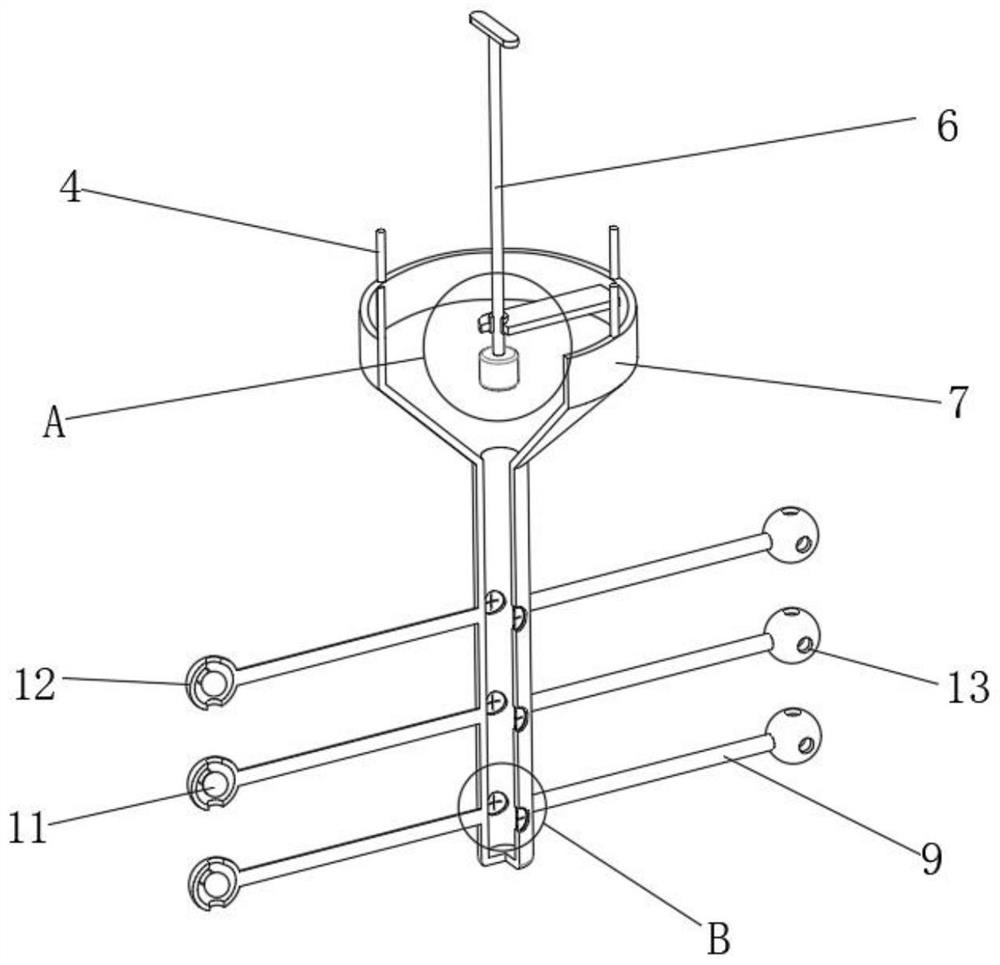

[0073] A kind of production method of the CCM that is used for fuel cell membrane electrode, such as Figure 1-6 shown, including: anode catalyst Pt / Ti 4 o 7 Preparation method, cathode catalyst graphite carbon supported platinum cobalt manganese (Pt 6 co 1 mn 1 / GC) preparation method, the preparation method of anode slurry, the preparation method of cathode slurry and the spraying preparation method of CCM;

[0074] Among them, the anode catalyst Pt / Ti 4 o 7 The preparation method comprises the steps:

[0075] S1: First set H 2 PtCl 6 solution, Ti 4 o 7 The powder and volatile solvent are evenly mixed and dispersed by the stirring device to form a paste;

[0076] S2: Then put the paste into a low-temperature environment of -55°C and freeze for 3 hours to obtain frozen paste H 2 PtCl 6 / Ti 4 o 7 ;

[0077] S3: Then dry under vacuum conditions from -55°C to 85°C for 20h to obtain H 2 PtCl 6 / Ti 4 o 7 powder;

[0078] S4: finally H 2 PtCl 6 / Ti 4 o 7 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com