Adhesive composition, UV viscosity-reducing adhesive tape and preparation method thereof

A composition and adhesive technology, applied in the directions of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problem of high peeling force, and achieve the effect of high adhesion, low pollution and easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

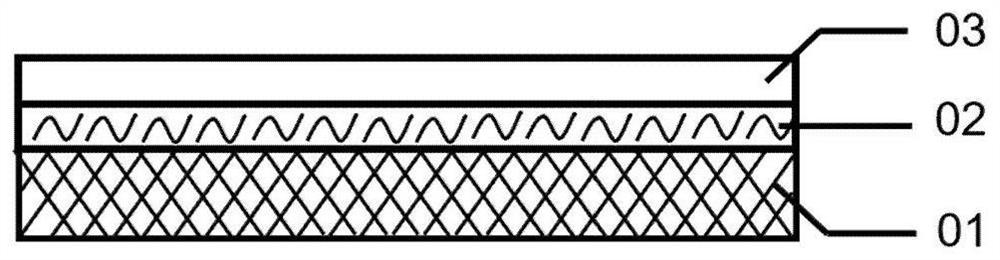

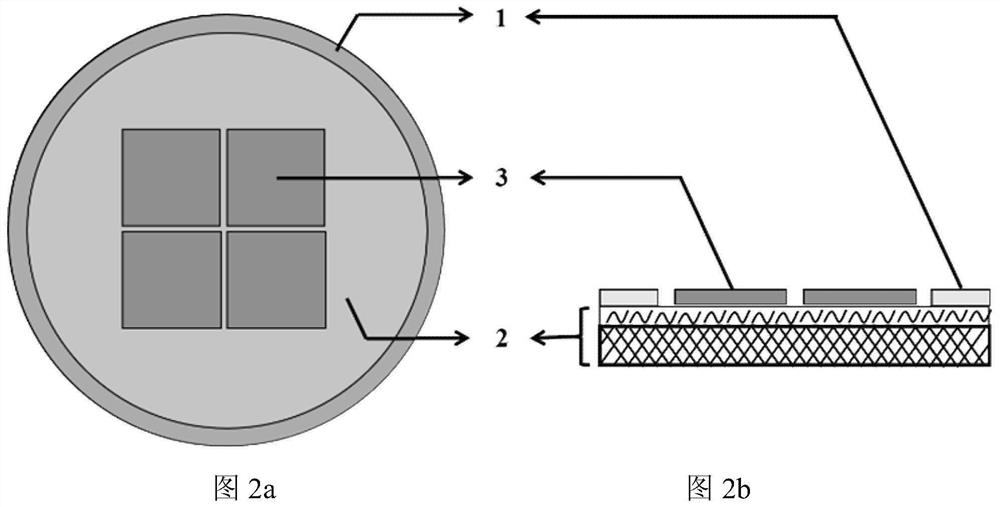

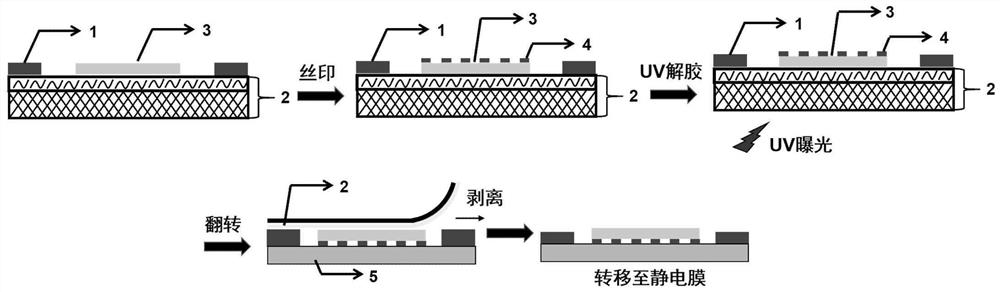

[0073] The invention provides an adhesive composition and a detackifying adhesive tape applied to IRCF screen printing process protection.

[0074] Select methyl acrylate unit (50%), butyl acrylate unit (45%), vinyl acetate unit (1.5%), 2-hydroxyethyl acrylate unit (2.0%) and (meth)acrylic acid unit (1.5%) , synthesize (meth)acrylate copolymer through solution polymerization method, the weight average molecular weight of (meth)acrylate copolymer is about 500,000-600,000, weigh 100.0 mass parts (meth)acrylate copolymer; Aromatic urethane acrylate oligomer (commercially available) with 6 vinyl functional groups, molecular weight 5000-15000, weighing 5.0 parts by mass; choose polytoluene diisocyanate trimer as curing agent (manufactured by Tosoh Chemical: CORONATE L ), weighing 1.5 parts by mass; select 30% of compounded 1-hydroxycyclohexyl phenyl ketone (BASF company: IRGACURE 184) and 70% of 2,4,6-trimethylbenzoyl diphenyl phosphine oxide (BASF Corporation: DAROCUR TPO) was us...

Embodiment 2

[0077] Select the (meth)acrylate copolymer as in Example 1, the weight-average molecular weight is 50-600,000, weigh 100.0 parts by mass; select the aromatic urethane acrylate oligomer containing 6 vinyl functional groups (commercially available) ), molecular weight 5000-15000, weighing 1.0 parts by mass; choose polytoluene diisocyanate trimer as curing agent (Tosoh Chemical: CORONATEL), weigh 1.5 parts by mass; choose compound 30% 1-hydroxycyclohexyl Phenyl ketone (manufactured by BASF: IRGACURE 184) and 70% of 2,4,6-trimethylbenzoyldiphenylphosphine oxide (manufactured by BASF: DAROCUR TPO) as photoinitiators, weighing 3.0 mass share.

[0078] The adhesive composition of the above formula, 100 μm PET substrate (commercially available, Young's modulus of elasticity 3550Mpa) and release film are made into adhesive tape according to the method provided by the present invention, and the thickness of the adhesive layer is 20 μm. Evaluate the performance of the adhesive break tap...

Embodiment 3

[0080] Select the (meth)acrylate copolymer as in Example 1, the weight-average molecular weight is 50-600,000, weigh 100.0 parts by mass; select the aromatic urethane acrylate oligomer containing 6 vinyl functional groups (commercially available) ), molecular weight 5000-15000, weigh 10.0 parts by mass; choose polytoluene diisocyanate trimer as curing agent (Tosoh Chemical: CORONATEL), weigh 1.5 parts by mass; choose compound 30% 1-hydroxycyclohexyl Phenyl ketone (manufactured by BASF: IRGACURE 184) and 70% of 2,4,6-trimethylbenzoyldiphenylphosphine oxide (manufactured by BASF: DAROCUR TPO) as photoinitiators, weighing 3.0 mass share.

[0081] The adhesive composition of the above formula, 100 μm PET substrate (commercially available, Young's modulus of elasticity 3550Mpa) and release film are made into adhesive tape according to the method provided by the present invention, and the thickness of the adhesive layer is 20 μm. Evaluate the performance of the adhesive break tape ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com