Monolithic solid amine adsorbent and preparation method thereof

A solid amine and adsorbent technology, which is applied in the field of monolithic solid amine adsorbent and its preparation, can solve the problems of difficult large-scale application and high energy consumption, and achieve the effects of excellent adsorption capacity, low energy consumption and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

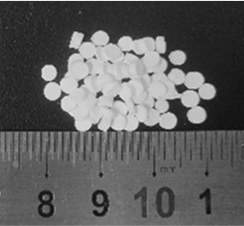

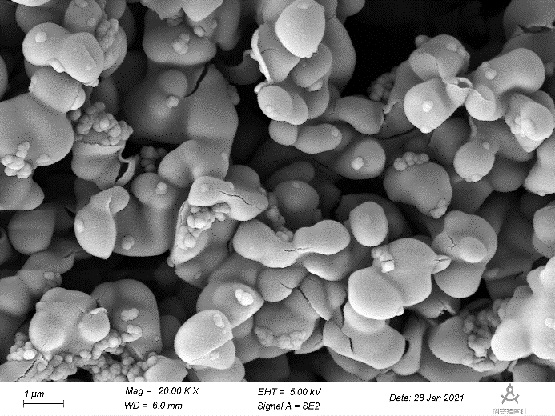

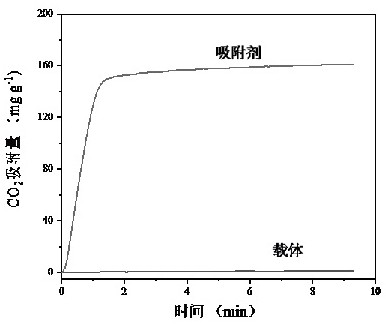

[0057] 7 g of tetraethylene pentamine was dissolved in 100 ml of absolute ethanol and stirred for 30 min. 3 g of the carrier obtained in Comparative Example 1 was added to the above solution, and stirring was continued for 30 min. Utilize the rotary evaporator to evaporate the ethanol, the temperature is 45 °C, and after removing the ethanol, the monolithic CO can be obtained 2 adsorbent, the adsorbent CO 2 The adsorption capacity is 190mg / g and the heat capacity is 2.79 J g -1 K -1 , to test the product, get Figure 1-4 .

Embodiment 2

[0059] Dissolve 3 g of tetraethylene pentamine in 100 ml of absolute ethanol and stir for 30 min. 3 g of the carrier obtained in Comparative Example 1 was added to the above solution, and stirring was continued for 30 min. Utilize the rotary evaporator to evaporate the ethanol, the temperature is 45 °C, and after removing the ethanol, the monolithic CO can be obtained 2 adsorbent, the adsorbent CO 2 The adsorption capacity is 154mg / g and the heat capacity is 2.40 J g -1 K -1 .

Embodiment 3

[0061] Dissolve 3 g of tetraethylene pentamine in 100 ml of absolute ethanol and stir for 30 min. 3 g of the carrier obtained in Comparative Example 2 was added to the above solution, and stirring was continued for 30 min. Utilize the rotary evaporator to evaporate the ethanol, the temperature is 45 °C, and after removing the ethanol, the monolithic CO can be obtained 2 adsorbent, the adsorbent CO 2 The adsorption capacity is 144mg / g and the heat capacity is 2.35 J g -1 K -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com