Manufacturing process and using method of drum screen

A manufacturing process and technology of trommel screen, applied in chemical instruments and methods, sieves, solid separation, etc., can solve the problems of high cost, increasing the difficulty of conventional equipment, and difficulty in rapid processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

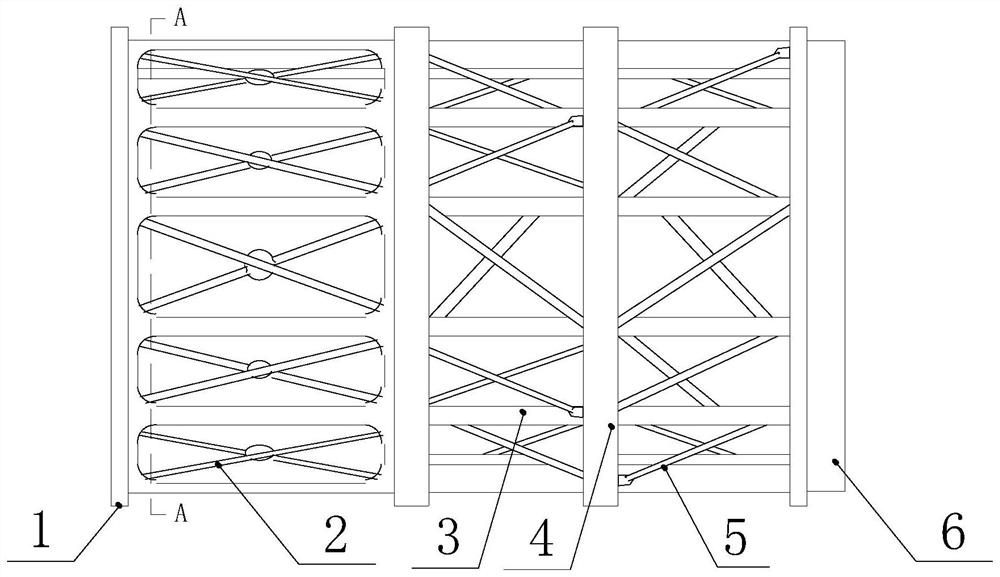

[0028] like figure 1 , figure 2 and Figure 5 As shown, the manufacturing process of the trommel screen of the present invention includes a longitudinal frame 3 and a combined die frame 10, the two ends of the longitudinal frame 3 are respectively welded with an inlet flange 1 and an outlet flange 6, and the longitudinal frame 3 is welded with cross braces 2, Circumferential rods 4 and diagonal braces 5, in order to optimize the production process, the biggest problem in the common production process of the screen body - "frame combination hole processing" process optimization is carried out after the longitudinal frame 3 is blanked, and the longitudinal frame 3 is drilled first and then drilled. Assembly, welding.

[0029] In this embodiment, 38 combined holes of Φ15mm and 22 holes of Φ23mm are arranged on each longitudinal frame 3, and the allowable parallelism error of the holes on each two longitudinal frames 3 is less than 1mm. Drilling die, when processing, first fit...

Embodiment 2

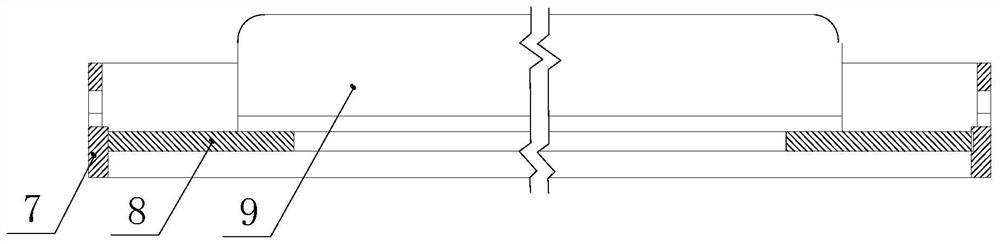

[0031] see image 3 , made further improvements on the basis of Example 1:

[0032] In this embodiment, the combined mold is composed of a cylinder 7 formed by a steel plate, an annular web 8, a T-shaped cross brace 9 and a combined mold skeleton 10. The annular web 8 and the T-shaped cross brace 9 reinforce the cylinder 7 function to prevent the "combination mold" from being deformed.

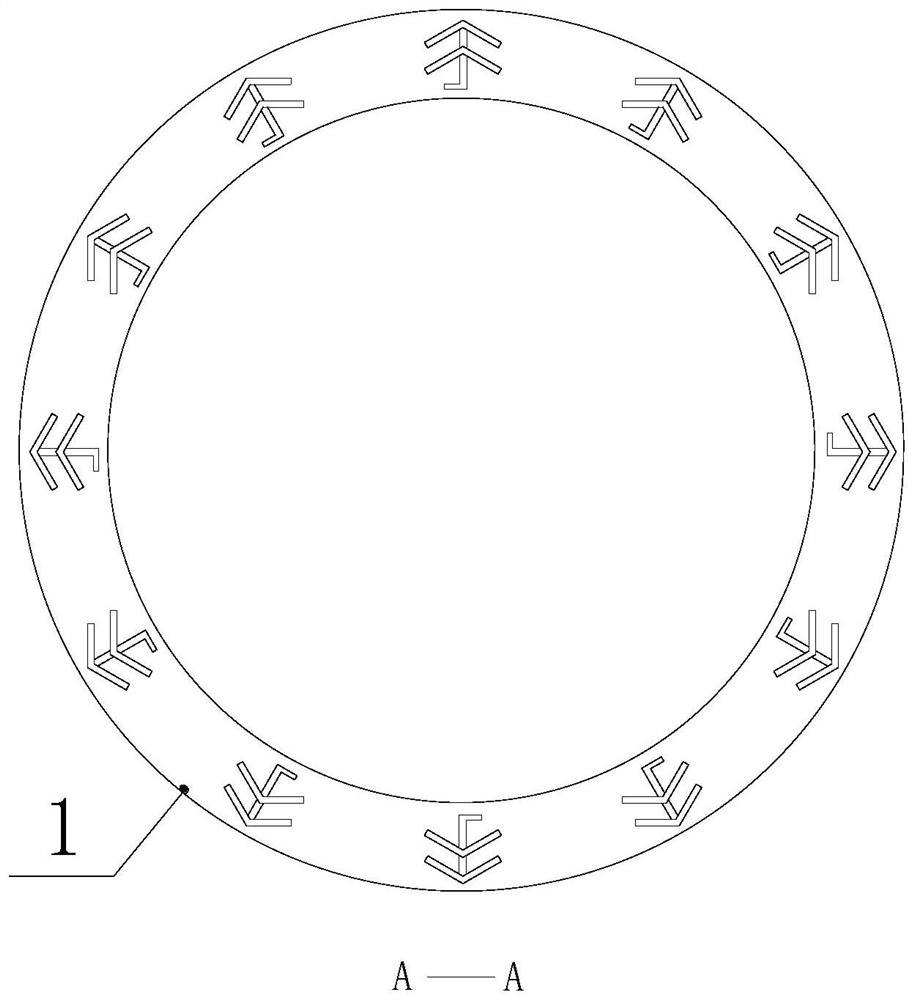

[0033] There are 12 positioning holes evenly distributed on the upper circumference of the inner side of the cylinder 7, and two shaft diameters for positioning are machined on the pin shaft, which are respectively matched with the positioning holes of the combined mold and the corresponding holes of the combined mold frame 10. Position the 12 combined mold skeletons 10 on the circumference to meet the requirements of the drawing; the axial distance between the two positioning shaft diameters on the pin shaft controls the inner diameter of the assembled screen body. After the combined mold is...

Embodiment 3

[0035] see figure 1 and Figure 4 , made further improvements on the basis of Example 1:

[0036] In order to drill and pass the inspection of the longitudinal frame 3 and the combined mold frame 10 to determine the position of each other through the pin shaft to ensure accurate assembly, first install four combined mold frames 10 in the 90° direction, and then vertically assemble them to the inlet flange 1 On the end face of the upper and lower composite molds, the combined mold frame 10 is aligned with the cross center line marked on the surface of the inlet flange 1, so that the centers of the upper and lower combined molds coincide with the center of the inlet flange 1.

[0037] In this embodiment, a laser measuring instrument is used to correct and align the verticality of the combined mold frame 10 and the inlet flange 1 and the parallelism between the centerlines of the combined holes of every two combined mold frames 10, tighten the pins and nuts, The combined mold f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap