Polyaryl anion exchange membrane and preparation method thereof

An anion-exchange membrane and polyaryl-based technology, which is applied in the field of anion-exchange membrane fuel cells, can solve the problems of reduced mechanical properties and shortened membrane life, and achieve good mechanical properties, improved alkali resistance, and simple and efficient methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

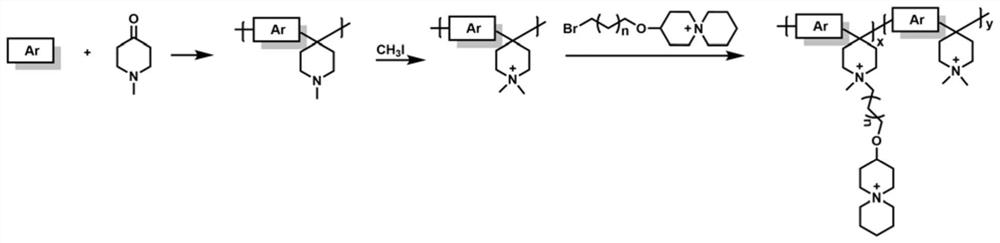

[0063] A kind of preparation method of polyaryl type anion exchange membrane, its steps are as follows:

[0064] (1) Preparation of cationic precursors

[0065] Pour 4-hydroxypiperidine into the container, add chloroform, then add potassium carbonate to the round-bottomed flask, stir, and finally add 1,5-dibromopentane to the stirring mixture slowly, and the heating reaction ends Then, it was precipitated with ethyl acetate and washed three times to obtain a cationic precursor, which was dried for later use;

[0066] (2) Preparation of side chain-containing spiro cations

[0067] The cationic precursor prepared in step (1) was added into the container, and DMF was added. After the raw materials were dissolved, NaH was added under ice bath conditions. After stirring for four hours, dibromoalkane was added. The supernatant is precipitated with ethyl acetate and washed three times to obtain cations containing side chains, which are dried for later use;

[0068] (3) Preparation...

Embodiment 1

[0077] A kind of preparation method of polyaryl type anion exchange membrane, its steps are as follows:

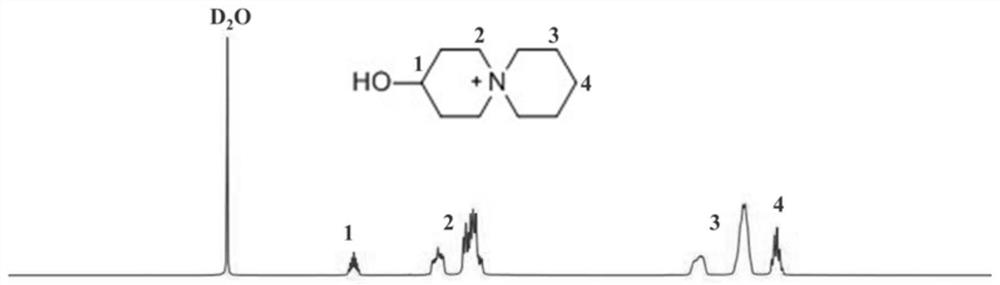

[0078] (1) Preparation of cationic precursors

[0079] Pour 4g 4-hydroxypiperidine into the container, add 60ml chloroform, then add 2g potassium carbonate to the round bottom flask, stir, and finally add 4.5ml 1,5-dibromopentane slowly to the stirring mixture , heated at 60 °C, reacted for 24 h, precipitated with 100 ml of ethyl acetate, and washed three times to obtain a cationic precursor, which was dried for later use;

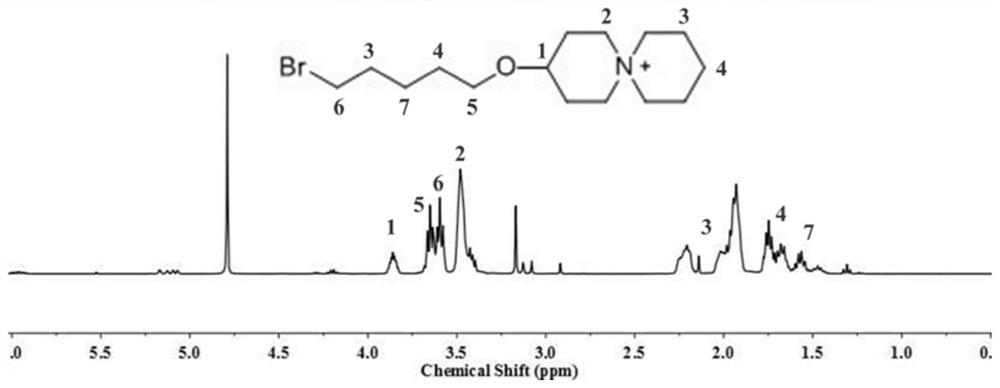

[0080] (2) Preparation of side chain-containing spiro cations

[0081] Add 1.5 g of the cationic precursor prepared in step (1) into the container, add 20 ml of DMF, after the raw materials are dissolved, under ice bath conditions, add 0.6 g of NaH, and after stirring for four hours, add 3 ml of 1,5-dibromopentane alkane, heated at 60°C, and reacted for 48h, the supernatant in the flask was precipitated with 50ml of ethyl acetate, and washed three ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com