Lignin amine macroporous anion exchange resin as well as preparation method and application thereof

A lignin amine and exchange resin technology, applied in ion exchange water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve resin poisoning, unfavorable ion exchange kinetic process, and difficulty in resin regeneration and other problems, to achieve the effect of reducing the preparation cost, improving the ion exchange efficiency and desorption regeneration ability, and improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

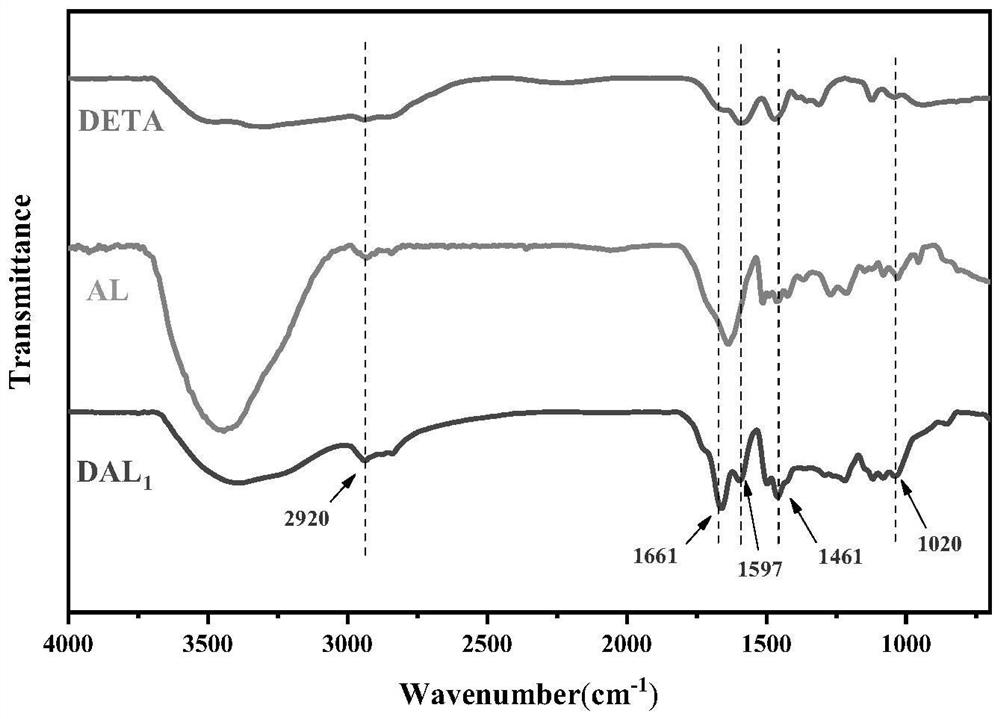

[0038] Dissolve 10g alkali lignin (raw material from Xiangjiang alkali lignin provided by Hunan Yongzhou Xiangjiang Paper Co., Ltd., the same below) in 20 parts of water, and adjust pH=12 with sodium hydroxide solution; add 4g diethylenetriamine, Under nitrogen protection, the mixture was stirred and dissolved evenly at room temperature, heated to 95°C, and then 5 g of formaldehyde was added dropwise; after the dropwise addition, the reaction was kept at 95°C for 3 hours. Then add 5g epichlorohydrin, use solvent water as the porogen in the curing stage, and cure at 80°C for 12 hours to obtain a blocky ligninamine macroporous anion exchange resin, which can be pulverized to obtain a particle size of 0.5mm ligninamine macroporous anion exchange resin.

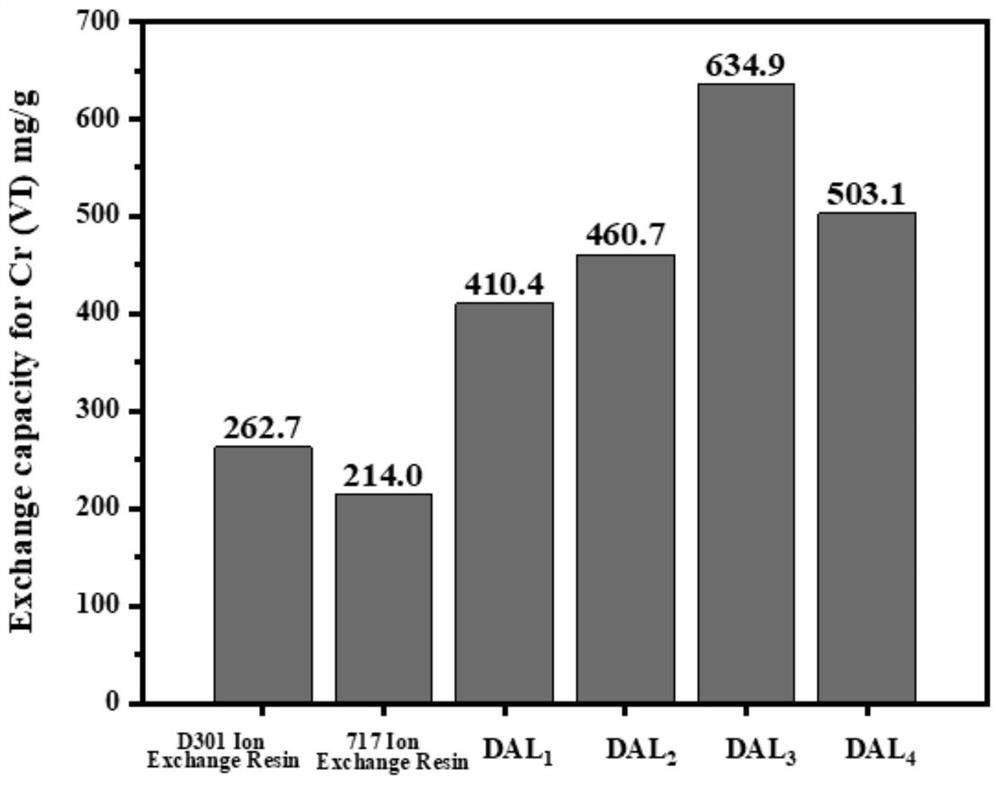

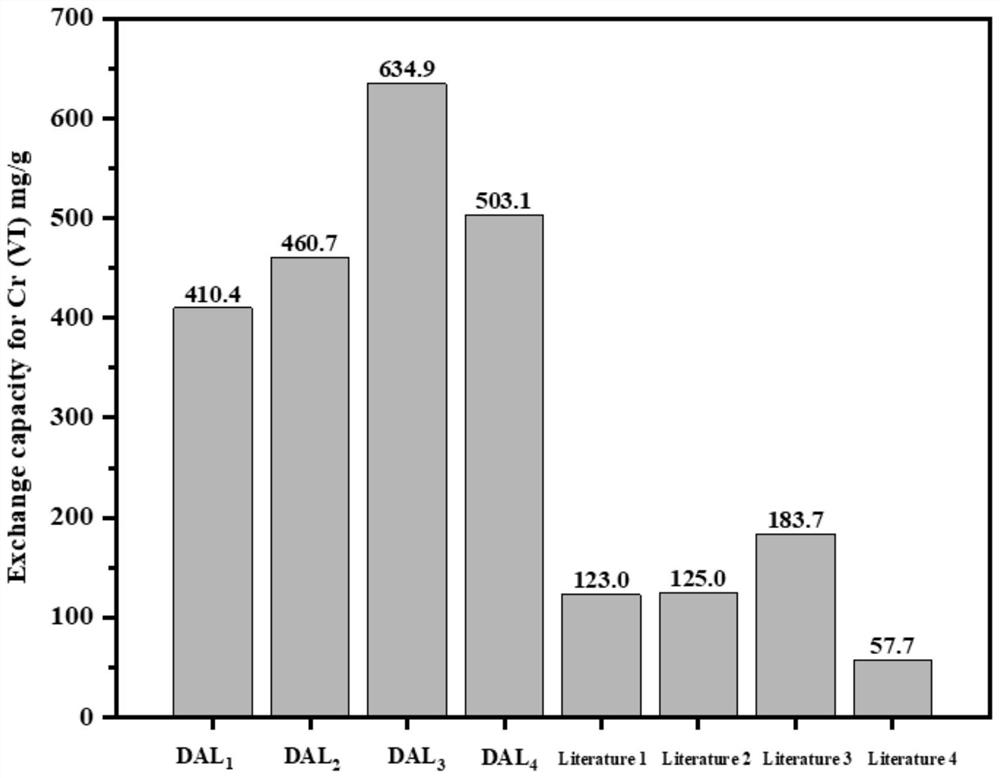

[0039] The ligninamine macroporous anion exchange resin prepared in Example 1 is named DAL 1 . DAL in this embodiment 1 The average pore size is 520 nm, the porosity is 54.8%, the lignin content is 46.0%, the dry basis exchang...

Embodiment 2

[0041]Dissolve 10g of alkali lignin in 20 parts of water, adjust pH=12 with sodium hydroxide solution; add 6g of diethylenetriamine, stir and dissolve evenly at room temperature under nitrogen protection, heat up to 95°C, and then dropwise add 7g of formaldehyde ; After the dropwise addition, the reaction was incubated at 95°C for 3 hours. Then add 5g epichlorohydrin, use solvent water as the porogen in the curing stage, and cure at 80°C for 12 hours to obtain a blocky ligninamine macroporous anion exchange resin, which can be pulverized to obtain a particle size of 0.5mm ligninamine macroporous anion exchange resin.

[0042] The ligninamine macroporous anion exchange resin prepared in Example 2 is named DAL 2 . DAL in this embodiment 2 The average pore size of Cr(VI) is 482 nm, the porosity is 50.2%, the lignin content is 52.47%, the dry basis exchange capacity for Cr(VI) reaches 460.7 mg / g, and the 4 2- The dry basis exchange capacity of 201.8 mg / g, for PO 4 3- The dr...

Embodiment 3

[0044] Dissolve 10g of alkali lignin in 20 parts of water, adjust pH=12 with sodium hydroxide solution; add 8g of diethylenetriamine, stir and dissolve evenly at room temperature under nitrogen protection, heat up to 95°C, and then dropwise add 9.3g formaldehyde; after the dropwise addition, the reaction was kept at 95°C for 3 hours. Then add 5g epichlorohydrin, use solvent water as the porogen in the curing stage, and cure at 80°C for 12 hours to obtain a blocky ligninamine macroporous anion exchange resin, which can be pulverized to obtain a particle size of 0.5mm ligninamine macroporous anion exchange resin.

[0045] The ligninamine macroporous anion exchange resin prepared in Example 3 is named DAL 3 . DAL in this embodiment 3 The average pore size is 615 nm, the porosity is 67.5%, the lignin content is 46.15%, the dry basis exchange capacity for Cr(VI) reaches 634.9 mg / g, and the exchange capacity for SO is 634.9 mg / g. 4 2- The dry basis exchange capacity of 186.2 mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com