Micropore laser processing method based on scanning path control

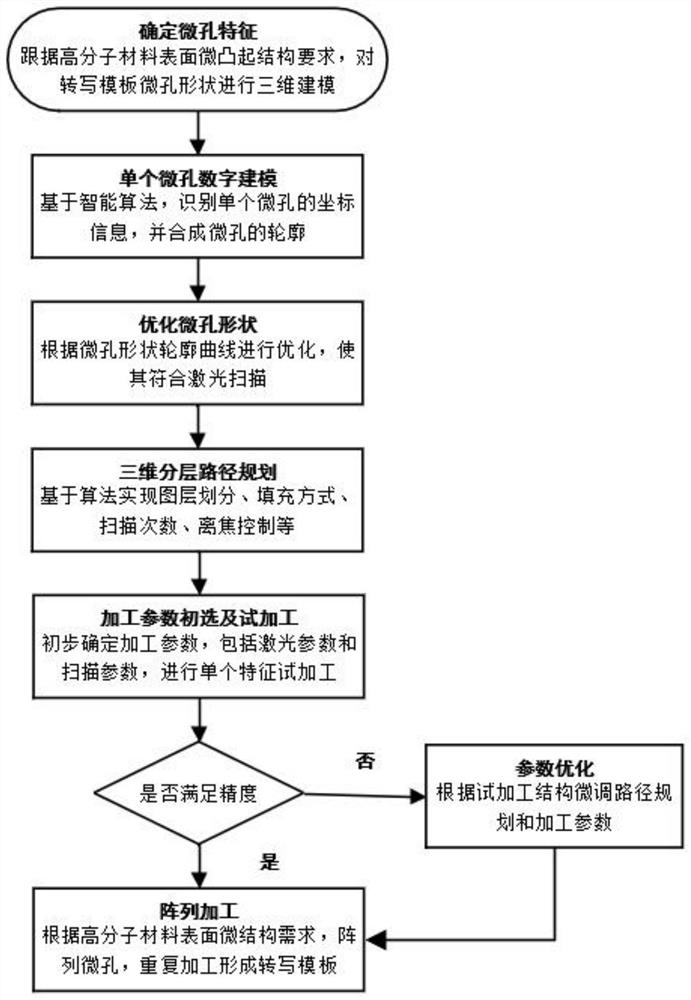

A laser processing method and scanning path technology, which are applied in the field of microhole laser processing based on scanning path control, can solve the problems of inability to meet the functional requirements of the surface structure of polymer materials, monotonous processing of micropores on the surface of templates, etc., and improve surface quality , enrich the shape and function, improve the effect of quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

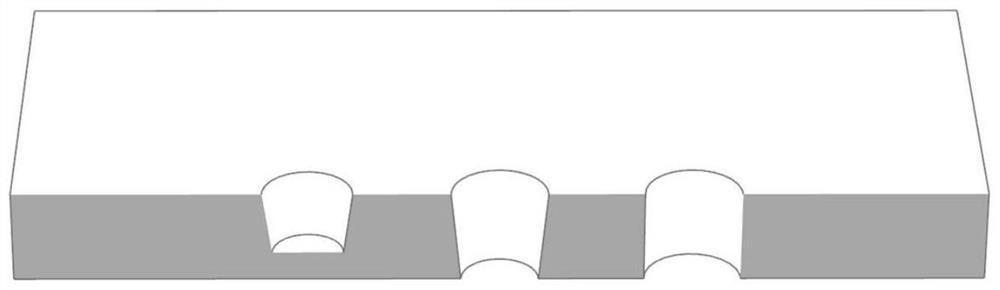

[0041] Taking the machining of tooth-shaped micro-taper holes as an example, the machining process of this method is described in detail.

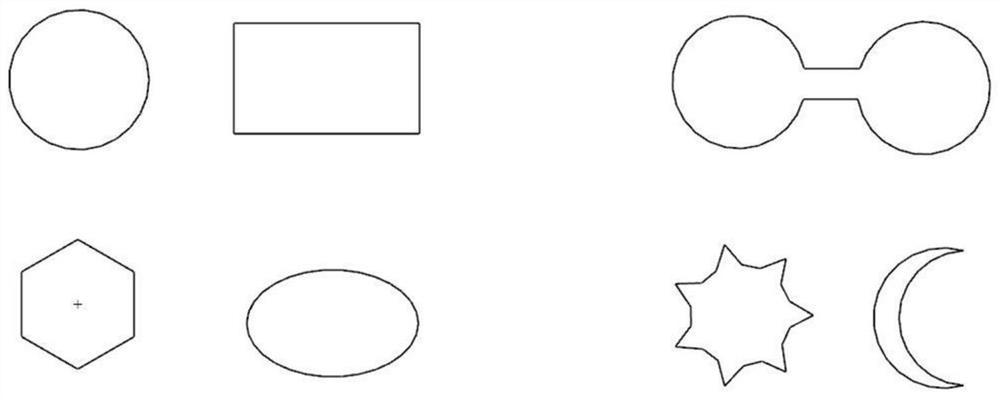

[0042] like Figure 4 As shown, the toothed microcones have complex contour shapes, and the toothed surface can form a secondary structure, providing richer functionality for the polymer microprotrusion surface, and the change of the tapered section and angle can adjust the sensitivity of the functional response . The micro-hole machining of the tooth-shaped micro-cone transcription template is carried out according to the following steps:

[0043] Firstly, according to the shape characteristics and size of the tooth-shaped micro-cone, a 3D model of a single micro-pore feature is established. In order to ensure that the micro-protrusion structure is consistent with the design size after demolding, the micro-pore feature modeling follows the expansion of the corresponding polymer material during the transfer process. and contraction laws....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com