Bismuth carbonate nano material as well as preparation method and application thereof

A nanomaterial, bismuth carbonate technology, applied in the field of electrochemistry, can solve the problems of electric energy waste, inappropriate large-scale use, large grid impact, etc., achieve high catalytic activity and selectivity, improve catalytic reduction ability, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

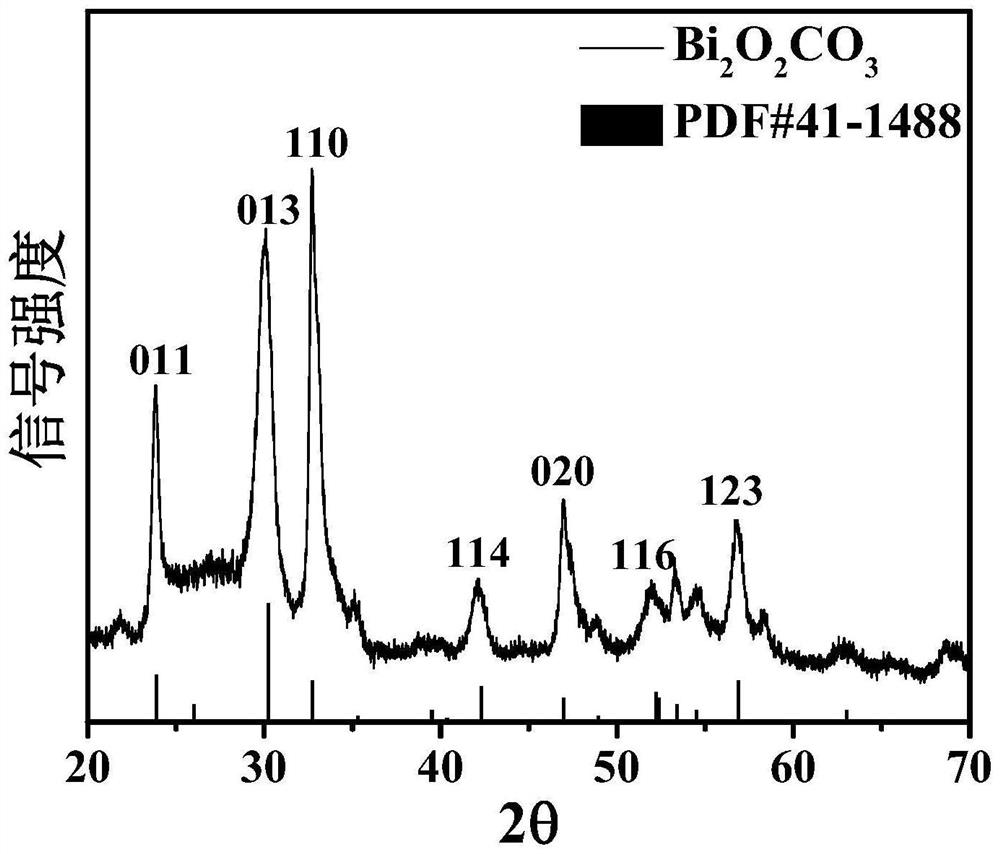

[0035] The present embodiment is the preparation of bismuth carbonate, and the specific preparation steps are as follows:

[0036] Dissolve 0.272 g of sodium acetate trihydrate in 20 ml of deionized water by sonication, named solution 1, and then add Bi(NO 3 ) 3 .5H 2 O (0.972g) and ethylene glycol (50ml) were mixed for 20min, named as solution 2, the solution 1 and solution 2 were mixed and ultrasonicated for 1 hour, then the solution was transferred to the autoclave and the temperature of the reaction was set to 180 degrees and the reaction time For 12 hours, after the solution is cooled, mix with ethanol and water in a volume ratio of 1:1, then set the rotating speed to 8000 for centrifugal washing 6 times, and finally dry in a 60-degree oven for 12 hours to obtain bismuth carbonate nanomaterials.

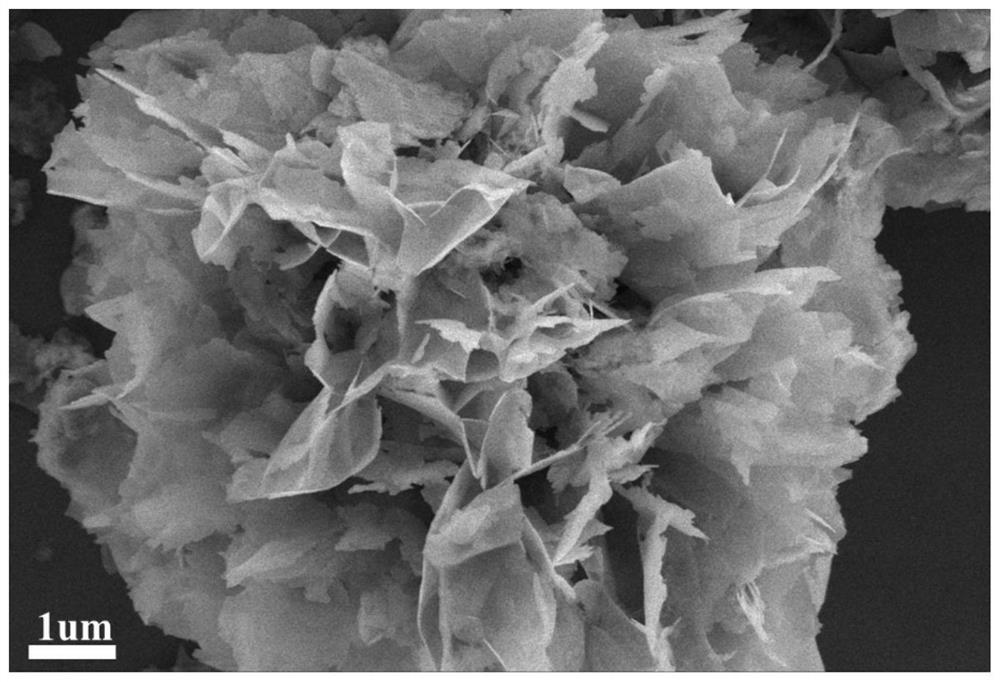

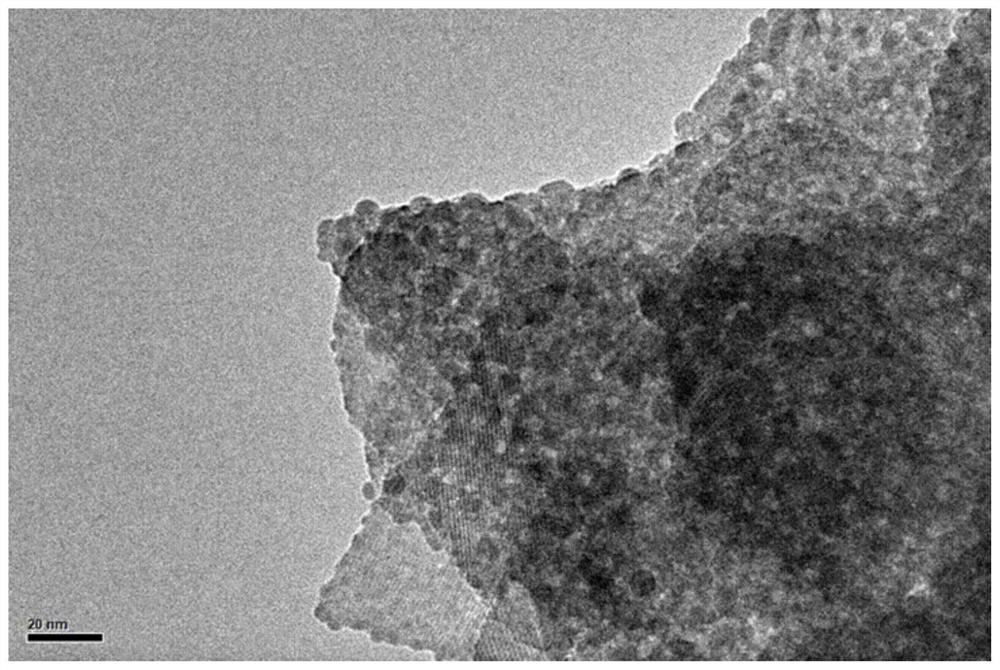

[0037] refer to figure 1 , which corresponds to the SEM image of the bismuth carbonate nanosheets composed of uniformly distributed nanoparticles of the present invention. It...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com