High-barrier nylon as well as preparation method and application thereof

A high-barrier, nylon technology, applied in the field of polymer materials, can solve the problems of reducing food storage time, food deterioration, and oxidation of contents, and achieve the effects of stable properties, increased compatibility, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

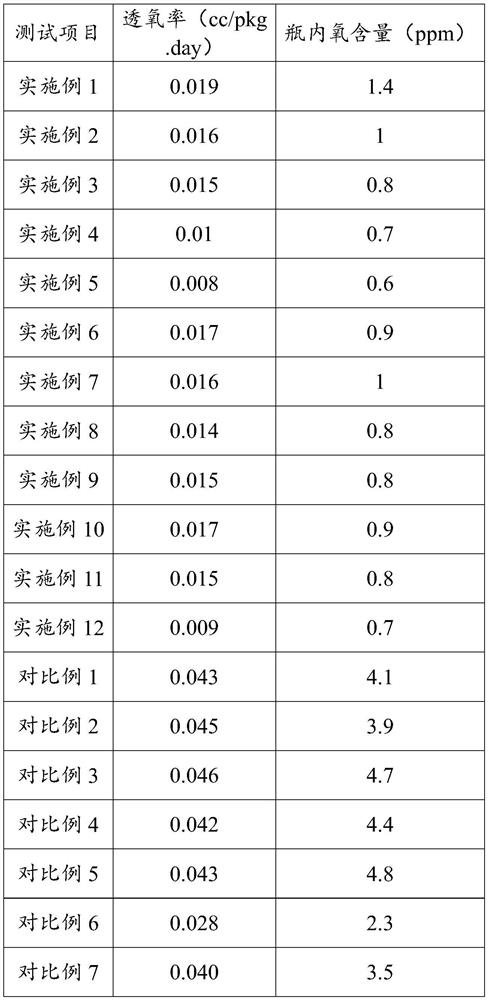

Examples

Embodiment 1

[0029] An embodiment of the high-barrier nylon and its preparation method and application of the present invention.

[0030] The preparation method of the product comprises the following steps:

[0031] Put 99 parts of nylon 6 (produced by Shenma Group) into the main feeding port of the twin-screw extruder, and then inject 0.001 part of supercritical fluid carbon dioxide and 1 part of unsaturated binary into the side feeding port of the twin-screw extruder. Carboxylic acid fumaric acid and 1.0 part of transition metal element catalyst cobalt isooctanoate are mixed, melted and kneaded at 240°C, cast, extruded and diced to obtain the high-barrier nylon particles. The nylon particles are injected by an injection molding machine and blown by a blow molding machine to obtain a high-barrier nylon bottle.

Embodiment 2

[0033] An embodiment of the high-barrier nylon and its preparation method and application of the present invention.

[0034] The only difference between this example and Example 1 is that the added part of the supercritical carbon dioxide is 0.005 part.

Embodiment 3

[0036] An embodiment of the high-barrier nylon and its preparation method and application of the present invention.

[0037] The only difference between this example and Example 1 is that the added part of the supercritical carbon dioxide is 0.01 part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com