Phase-change material capable of storing energy for long time at room temperature as well as preparation and application of phase-change material

A technology of phase change material and energy storage material, applied in heat exchange materials, energy storage, reduction of greenhouse gases, etc., can solve the problems of supercooling, phase separation, strong metal corrosion, etc., to achieve simple preparation process and convenient operation , the effect of excellent heat storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Dissolve 0.2 g of anionic polyacrylamide with a molecular weight of 500 W in 20 ml of water, and stir at room temperature for 5 hours to obtain a homogeneous polyacrylamide aqueous solution with a mass percentage concentration of 1%.

[0023] (2) 1.8 g of erythritol was added to the polyacrylamide aqueous solution in step (1), and stirred at room temperature for 2 h to form a homogeneous sugar alcohol polymer aqueous solution. The mass ratio of erythritol to polyacrylamide is 90:10.

[0024] (3) Transfer the prepared sugar alcohol polymer aqueous solution into a reagent bottle, dry the water at 110° C. under normal pressure for 16 hours, and obtain a phase change material loaded with erythritol and capable of long-term energy storage at room temperature.

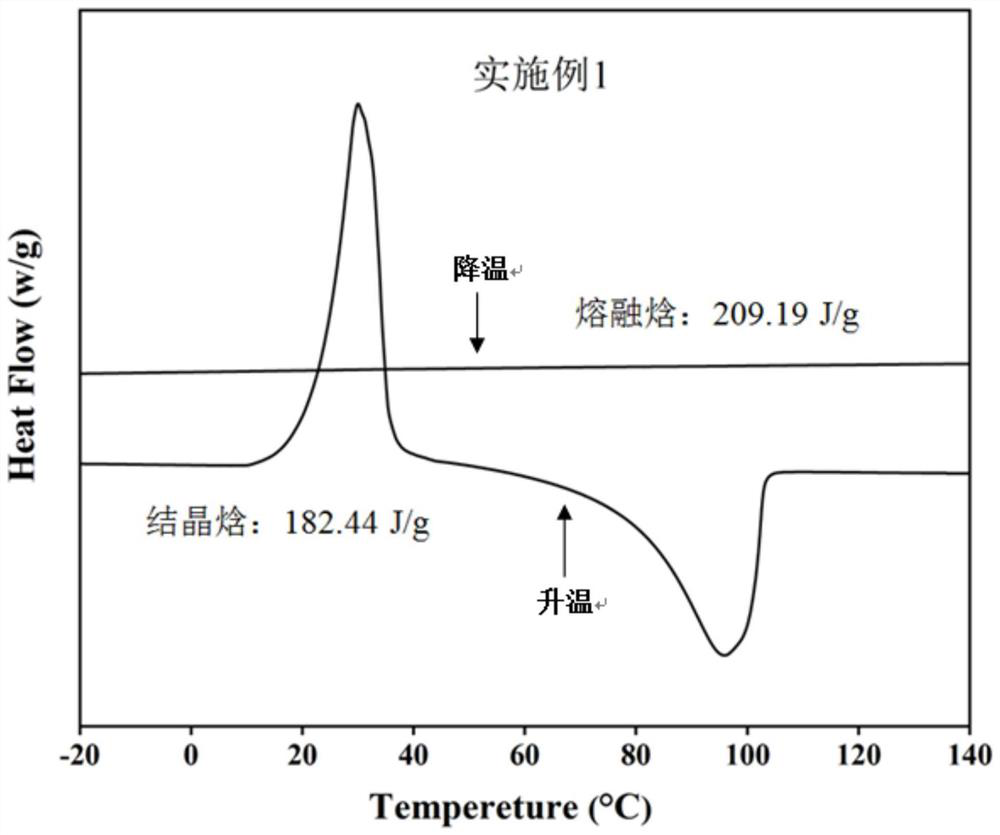

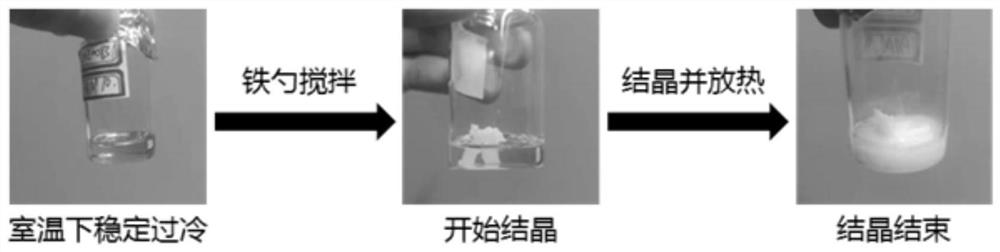

[0025] The prepared phase change material with long-term energy storage at room temperature is a transparent liquid, and the thermal analysis curve is as follows figure 1 As shown, the melting enthalpy is 209.19 ...

Embodiment 2

[0027] (1) Dissolve 0.4 g of nonionic polyacrylamide with a molecular weight of 500 W in 20 ml of water, and stir at room temperature for 5 hours to obtain a homogeneous polyacrylamide aqueous solution with a mass percentage concentration of 2%.

[0028] (2) 7.6 g of erythritol was added to the polyacrylamide aqueous solution in step (1), and stirred at room temperature for 2 h to form a homogeneous sugar alcohol polymer aqueous solution. The mass ratio of erythritol to polyacrylamide is 95:5.

[0029] (3) Transfer the prepared sugar alcohol polymer aqueous solution into a reagent bottle, dry the water at 80° C. under normal pressure for 48 hours, and obtain a phase change material loaded with erythritol and capable of long-term energy storage at room temperature.

[0030] The prepared phase change material that can store energy for a long time at room temperature is a transparent liquid, the melting enthalpy is 238.22 J / g, the cold crystallization enthalpy is 179.37 J / g, and ...

Embodiment 3

[0032] (1) Dissolve 0.32 g of anionic polyacrylamide with a molecular weight of 500 W in 16 ml of water, and stir at room temperature for 5 hours to obtain a homogeneous polyacrylamide aqueous solution with a mass percentage concentration of 2%.

[0033] (2) 3.68 g of erythritol was added to the polyacrylamide aqueous solution in step (1), and stirred at room temperature for 2 h to form a homogeneous sugar alcohol polymer aqueous solution. The mass ratio of erythritol to polyacrylamide is 92:8.

[0034] (3) Transfer the prepared sugar alcohol polymer aqueous solution into a reagent bottle, dry the water at 110° C. under normal pressure for 16 hours, and obtain a phase change material loaded with erythritol and capable of long-term energy storage at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting enthalpy | aaaaa | aaaaa |

| Melting enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com