Preparation method and application of uricase immobilized resin

A uricase and resin technology, applied in the field of enzyme immobilization, can solve problems such as health risks, influence on adsorption performance, chemical structure damage, etc., and achieve the effect of stable enzyme spatial structure, good biocompatibility, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

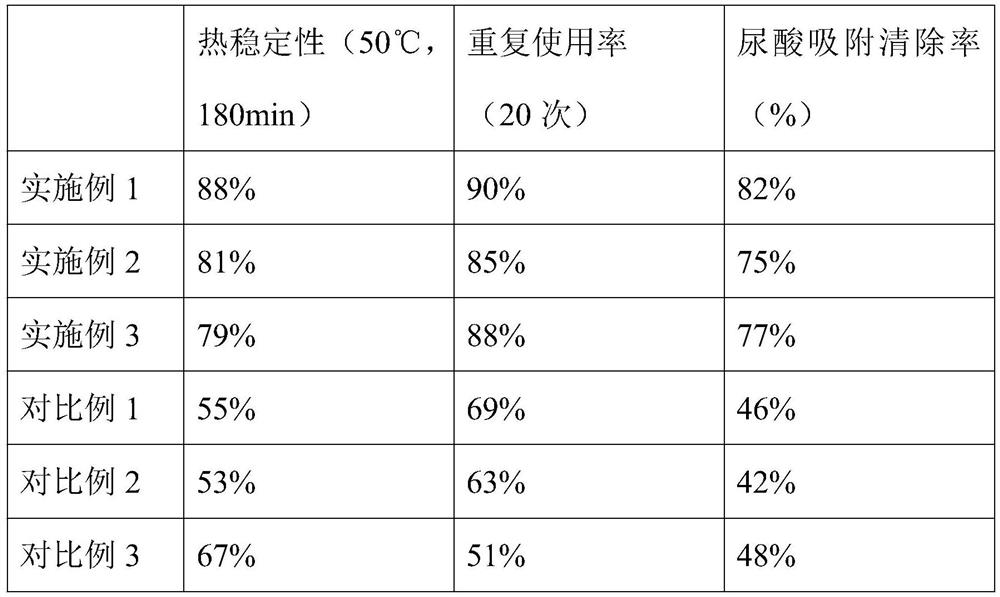

Examples

Embodiment 1

[0030] A preparation method of uricase immobilized resin, comprising the following steps:

[0031] (1) The purified recombinant uricase was prepared into 25 mL of enzyme solution with a concentration of 2 g / L at room temperature, followed by adding a phosphate buffer (75 mL) with a pH of 7.0 and a concentration of 8 mmol / LEDTA solution (50 mL), and the mixture was shaken and mixed. uniform for 30min, and then EDTA-Cu was separated by molecular sieve chromatography. 2+ The chelate is removed from the reaction solution to obtain a Cu-free 2+ uricase solution, continue to add zinc sulfate solution (150 mL) with a concentration of 8 mmol / L, shake at a constant temperature of 20 ° C for 1 h, and separate and purify to obtain Zn 2+ Replaced uricase;

[0032](2) Disperse 70g of polystyrene resin particles in water, then add 30mL of concentrated nitric acid and 10mL of concentrated sulfuric acid, react at 45°C for 12h, centrifuge after the reaction is completed, wash with ultrapure ...

Embodiment 2

[0037] A preparation method of uricase immobilized resin, comprising the following steps:

[0038] (1) At room temperature, the purified recombinant uricase was prepared into 25 mL of an enzyme solution with a concentration of 4 g / L, followed by adding a phosphate buffer solution (75 mL) with a pH of 7.0 and a concentration of 12 mmol / L EDTA solution (60 mL), shaking Mixed for 45min, then EDTA-Cu was separated by molecular sieve chromatography 2+ The chelate is removed from the reaction solution to obtain a Cu-free 2+ uricase solution, continue to add zinc sulfate solution (175 mL) with a concentration of 12 mmol / L, shake at constant temperature for 1.5 h at 25 °C, and separate and purify to obtain Zn 2+ Replaced uricase;

[0039] (2) Disperse 70 g of polystyrene resin particles in water, then add 50 mL of concentrated nitric acid and 30 mL of concentrated sulfuric acid, react at 50°C for 14 hours, centrifuge after the reaction is completed, wash with ultrapure water to neut...

Embodiment 3

[0044] A preparation method of uricase immobilized resin, comprising the following steps:

[0045] (1) At room temperature, the purified recombinant uricase was configured into 25 mL of an enzyme solution with a concentration of 3 g / L, followed by adding a phosphate buffer solution (75 mL) with a pH of 7.0 and a concentration of 10 mmol / L EDTA solution (75 mL), shaking Mixed for 30-60min, then EDTA-Cu was separated by molecular sieve chromatography 2+ The chelate is removed from the reaction solution to obtain a Cu-free 2+ uricase solution, continue to add zinc sulfate solution (200 mL) with a concentration of 10 mmol / L, shake at a constant temperature of 20 ° C for 2 h, and separate and purify to obtain Zn 2+ Replaced uricase;

[0046] (2) Disperse 70g of polystyrene resin particles in water, then add 40mL of concentrated nitric acid and 20mL of concentrated sulfuric acid, react at 45°C for 10h, centrifuge after the reaction is complete, wash with ultrapure water to neutral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com