Cobalt-based composite electrode material based on anion exchange technology and preparation thereof

A composite electrode and exchange technology, which is applied in the field of cobalt-based composite electrode materials and its preparation, can solve the problems of particle aggregation, scalability, and adverse effects on electrochemical performance, and achieve simple and controllable preparation methods, cost-effectiveness and Scalability, Effects of Superior Supercapacitor Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Add 2.91g of cobalt nitrate hexahydrate and 3.28g of 2-methylimidazole into 125ml of methanol solution with a balance, stir fully to dissolve them completely, then slowly mix the two solutions together, stir Let stand for 10 minutes for 24 hours, then centrifuge at 8000r / min for 5 minutes, wash with absolute ethanol 3-5 times, and dry at 60°C for 12 hours to obtain purple ZIF-67 nanoparticles;

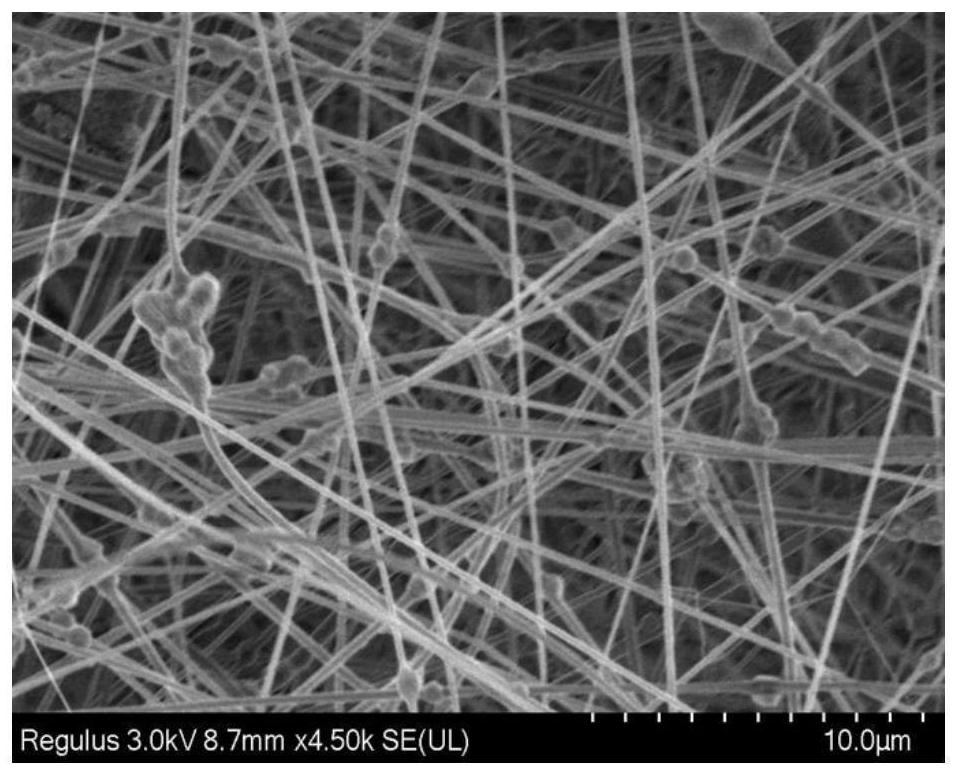

[0051] (2) Weigh 4.5g PAN with a balance and place it in 45.5g DMF solution and stir it under a magnetic stirrer for 24h. After obtaining a PAN solution with a concentration of 9%, put the ZIF-67 nanoparticles prepared above into the PAN solution, and then stirred under a magnetic stirrer for 12 hours, the final prepared spinning solution was dropped into the porous spinneret, and the nanofiber membrane loaded with ZIF-67 was prepared in batches by using an air-supplied porous electrospinning device;

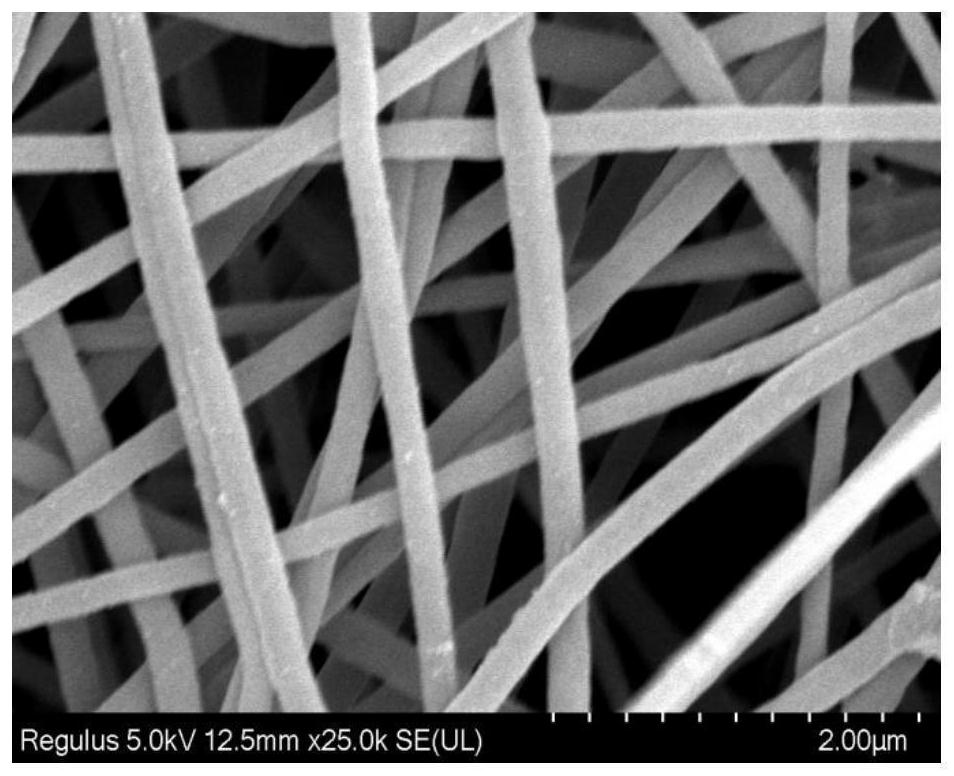

[0052] (3) Place the spun nanofiber membrane in an electric constant temp...

Embodiment 2

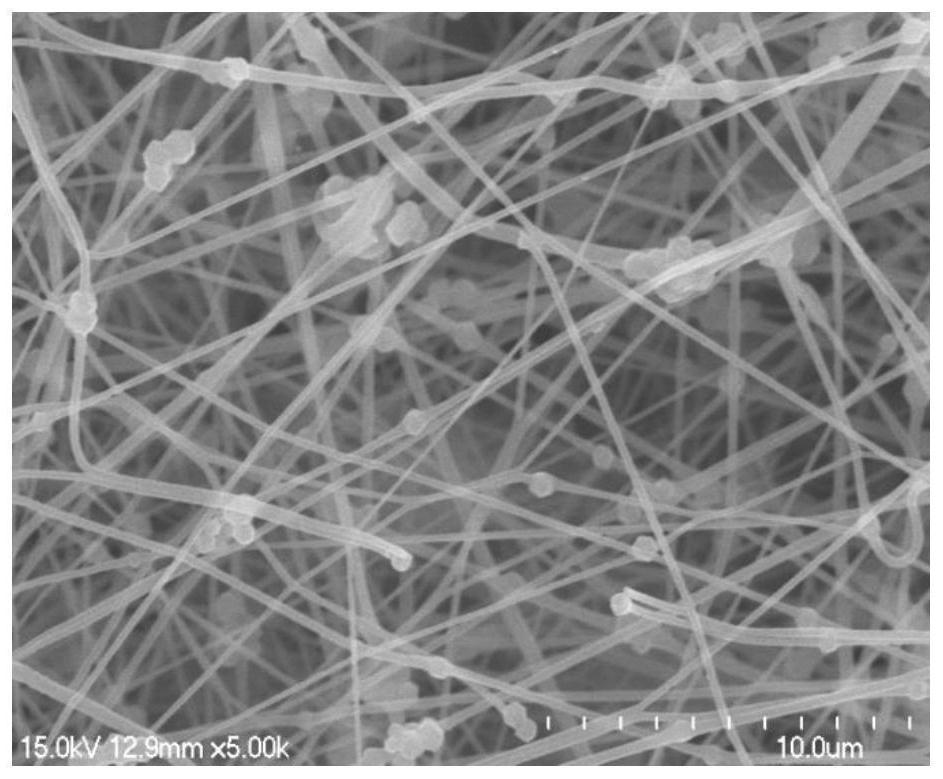

[0059] (1) Use a balance to weigh 4.5g of polyacrylonitrile, 2.91g of cobalt nitrate hexahydrate, and 3.28g of 2-methylimidazole into 45.5g of N,N-dimethylformamide solution, and stir for 24 hours under a magnetic stirrer , the prepared spinning solution is dropped into the porous spinneret, and the nanofiber membrane loaded with ZIF-67 is prepared by using the air-supplied porous electrospinning device;

[0060] (2) Dry in an electric constant temperature drying oven at room temperature for 16-24 hours, take it out and put it into a muffle furnace to pre-oxidize at 240°C at a heating rate of 2°C / min, and keep it at 240°C for 2h;

[0061] (3) Prepare 30-50 ml of NaOH solution with a pH of 11-12.5, and then place the pre-oxidized nanofibrous membrane in NaOH solution for 12 hours to perform anion exchange (under normal temperature and pressure);

[0062] (4) Place the exchanged nanofiber membrane in an oven, and dry at 60° C. for 12 to 16 hours. Finally, the above-mentioned na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com