Negative electrode electrolyte for zinc-iron flow battery

An anode electrolyte, flow battery technology, applied in fuel cells, organic electrolytes, non-aqueous electrolytes, etc., can solve the problems of short cycle life, low battery performance, etc., to improve performance and cycle life, improve battery performance and cycle Longevity and the effect of reducing the generation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

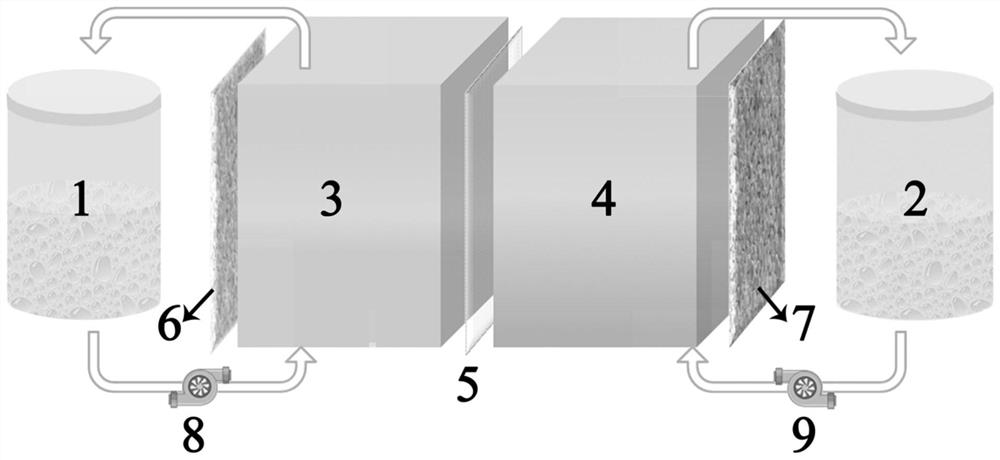

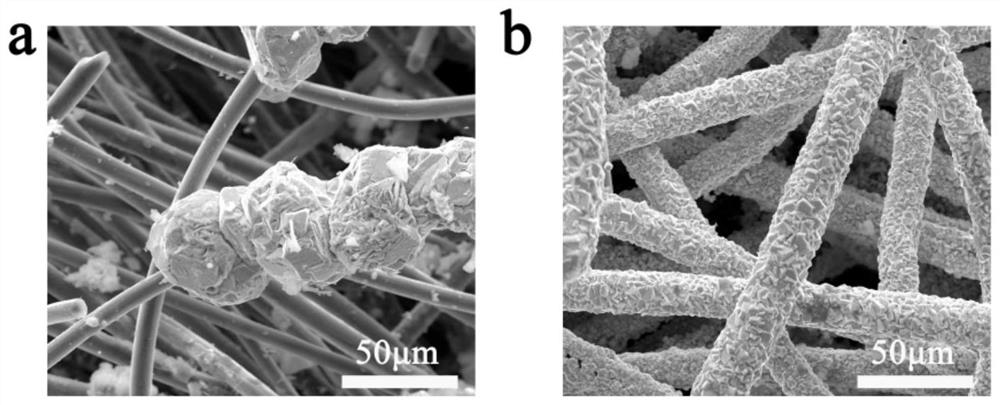

[0034] In this embodiment, the negative electrode electrolyte of the zinc-iron flow battery includes: zinc chloride, nicotinamide as an additive, potassium chloride as a supporting electrolyte, and deionized water as a solvent. Among them, the concentrations of zinc chloride, nicotinamide and potassium chloride were 0.5, 0.05, and 3 mol / L, respectively, and the areas of the positive and negative electrodes and the proton exchange membrane were both 4 × 7 cm. 2 .

[0035]The specific configuration steps of the negative electrolyte are as follows: Weigh 3.4g of zinc chloride particles in a beaker to dissolve in deionized water, then weigh 11.1g of potassium chloride to dissolve in deionized water, and then weigh 0.305g of nicotinamide to dissolve in deionized water Dissolve; pour the above solution into a 50mL volumetric flask, dilute to 50mL with deionized water and mix well.

[0036] Positive Electrolyte K 4 Fe(CN) 6 ·3H 2 The O concentration is 0.5mol / L, the supporting el...

Embodiment 2

[0042] In this example, the conditions were the same as those in Example 1.

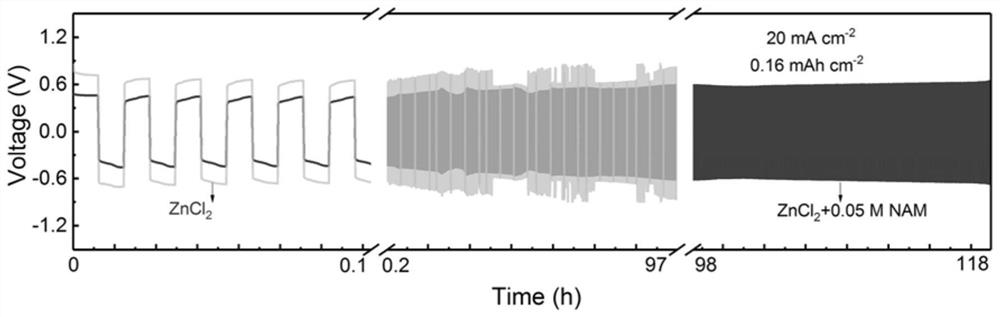

[0043] like Figure 4 (a), at 20mA cm -2 Under the conditions of current density, charging for 45min and then discharging to 0.5V for 15h, when nicotinamide is not added to the zinc chloride system flow battery, the coulombic efficiency of the flow battery is seriously attenuated, and the capacity retention rate is 63.9%. After adding nicotinamide to the zinc chloride system flow battery, such as Figure 4 As shown in (b), the coulombic efficiency of the flow battery at this time is almost not attenuated, and the capacity retention rate is 98.9%. In general, the addition of nicotinamide inhibits the side reaction of hydrogen evolution, reduces the generation of by-products, and ensures that the battery does not fail.

Embodiment 3

[0045] In this example, a constant temperature water bath was used to keep the temperature of the positive and negative electrolytes of the flow battery at 33°C, and other conditions were the same as those in Example 2. The result is as Figure 5 (a), at 20mA cm -2 When no nicotinamide is added to the zinc chloride system flow battery under the conditions of current density and charging for 10 minutes, the life of the flow battery is 200 cycles, and the battery cycle stability is poor and cannot guarantee long-term cycling. After adding nicotinamide to the zinc chloride system flow battery, such as Figure 5 As shown in (b), the cycle life of the battery is improved to 300 cycles while maintaining an energy efficiency of 85%. And the Coulomb efficiency is 100% without fluctuation, and the cycle stability and reversibility of the flow battery are significantly improved.

[0046] The results of the examples show that the negative electrode electrolyte used in the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com