Water-based composite latex applied to preparation of hydrophobic aluminum foil and synthesis process of water-based composite latex

A composite latex and synthetic process technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of large polarity difference between silicone hydrophobic agent and main resin, deterioration of mechanical properties of paint film, poor compatibility of two phases, etc., to achieve Excellent hydrophobicity, good construction efficiency and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A water-based composite latex used in the preparation of hydrophobic aluminum foil and its synthesis process. It is characterized in that its composition and relative proportions are:

[0026]

[0027]

[0028] Its synthesis process is as follows:

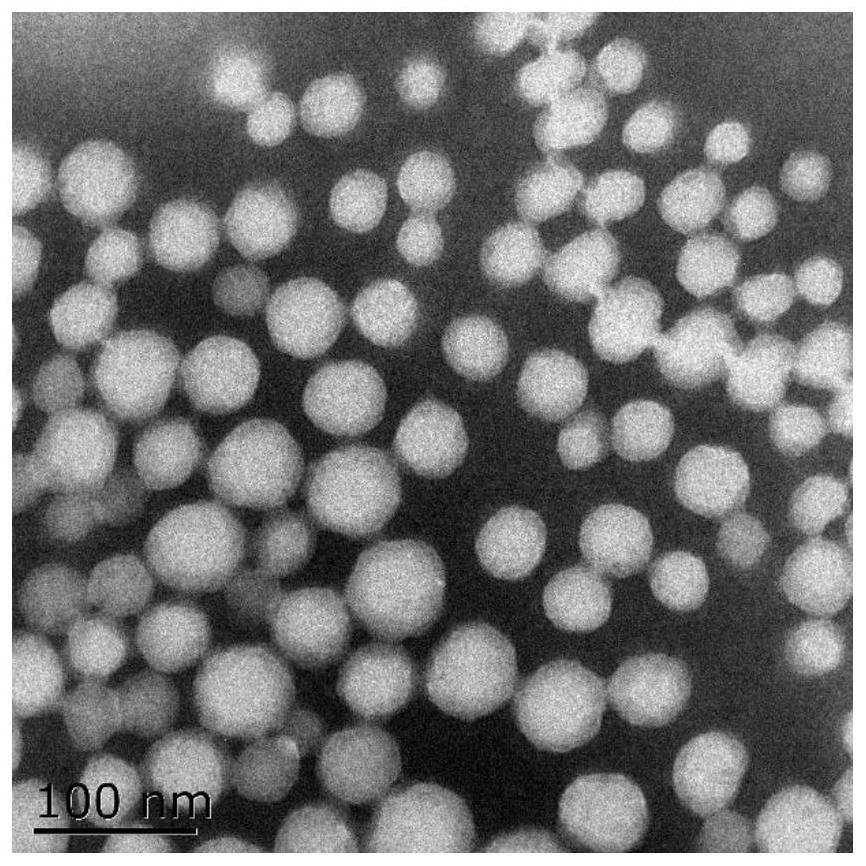

[0029] Step 1: Mix polyethylene glycol dimethacrylate with hydrogen-containing silicone oil, then add a platinum catalyst of 3ppm relative to the total mass of the two reactants, mix and stir, and react for 1 hour at a temperature range of 150°C to obtain two Polyethylene glycol methacrylate grafted with hydrogen-containing silicone oil.

[0030] Step 2: Mix polyethylene glycol dimethacrylate grafted hydrogen-containing silicone oil with acrylate monomer mixture, then add anionic emulsifier, and gradually add part of water and part of water-based initiator at the speed of high-speed mixer at 1000 rpm Agent, both are relative total amount 30%wt and 30%wt respectively. Under high-speed stirring, a pre-emulsion is obta...

Embodiment 2

[0040] A water-based composite latex used in the preparation of hydrophobic aluminum foil and its synthesis process. It is characterized in that its composition and relative proportions are:

[0041]

[0042] Its synthesis process is as follows:

[0043] Step 1: Mix polyethylene glycol dimethacrylate with hydrogen-containing silicone oil, then add a platinum catalyst of 4 ppm relative to the total mass of the two reactants, mix and stir, and react for 2 hours at a temperature range of 130°C to obtain di Polyethylene glycol methacrylate grafted with hydrogen-containing silicone oil.

[0044] Step 2: Mix polyethylene glycol dimethacrylate grafted hydrogen-containing silicone oil with acrylate monomer mixture, then add anionic emulsifier, and gradually add part of water and part of water-based initiator at the speed of high-speed mixer at 1200 rpm agent, both of which are respectively 40%wt and 40%wt relative to the total amount. Under high-speed stirring, a pre-emulsion is...

Embodiment 3

[0052] A water-based composite latex used in the preparation of hydrophobic aluminum foil and its synthesis process. It is characterized in that its composition and relative proportions are:

[0053]

[0054] Its synthesis process is as follows:

[0055] Step 1: Mix polyethylene glycol dimethacrylate with hydrogen-containing silicone oil, then add a platinum catalyst of 5 ppm relative to the total mass of the two reactants, mix and stir, and react for 5 hours at a temperature range of 120°C to 120°C , to obtain hydrogen-containing silicone oil grafted with polyethylene glycol dimethacrylate.

[0056] Step 2: Mix polyethylene glycol dimethacrylate grafted hydrogen-containing silicone oil with acrylate monomer mixture, then add anionic emulsifier, and gradually add part of water and part of water-based initiator at the speed of high-speed mixer at 1400 rpm agent, both of which are respectively 50%wt and 45%wt relative to the total amount. Under high-speed stirring, a pre-emu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap