Engineering bacterium for producing daptomycin and application thereof

A technology of daptomycin and engineering bacteria, applied in the field of genetic engineering, can solve the problems of low fermentation level and high cost of daptomycin, and achieve the effects of reducing production cost and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

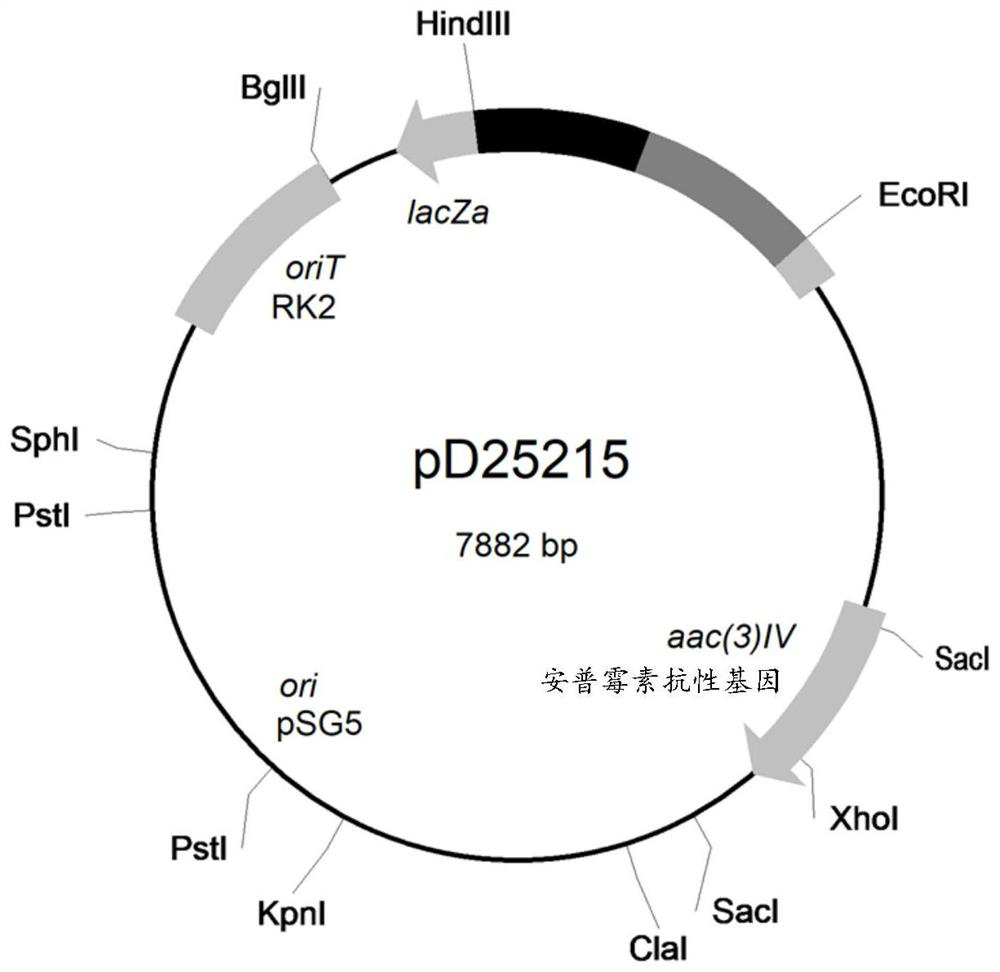

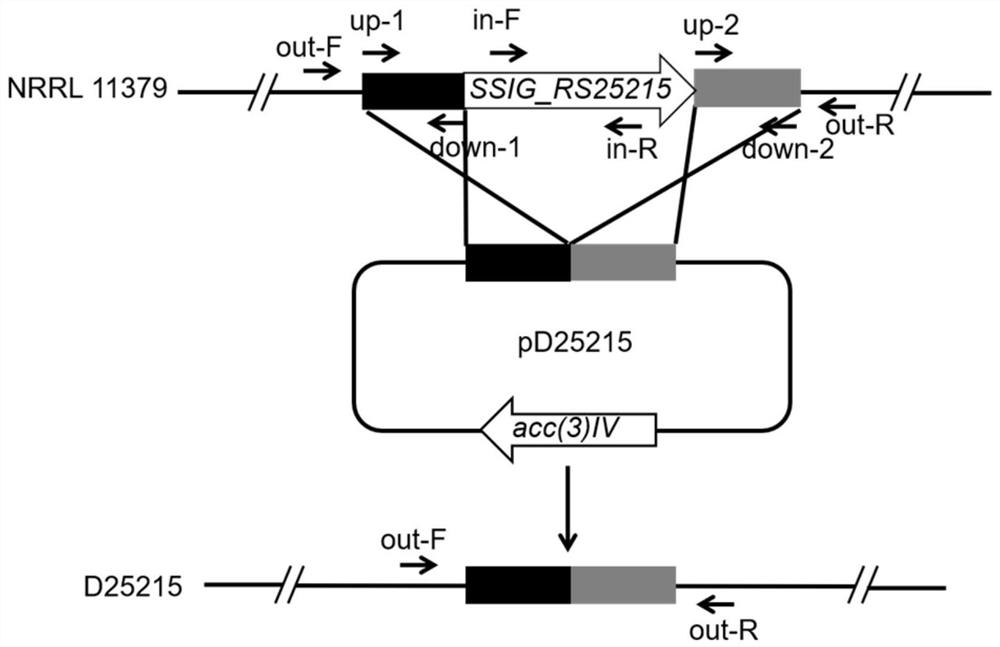

[0036] Embodiment 1: Construction of SSIG_RS25215 gene deletion vector

[0037] (1) Cloning of upper and lower arms of Streptomyces roseospora SSIG_RS25215 gene

[0038] According to the sequence of the SSIG_RS25215 gene, PCR primers for the upstream (up-1) and downstream (down-1) of the upper arm, and the PCR primers for the upstream (up-2) and downstream (down-2) of the lower arm were designed, as follows Table 1 shows.

[0039] Table 1.

[0040]

[0041] Using the genomic DNA of Streptomyces roseospora wild-type strain NRRL11379 as a template, PCR amplification was performed with primer pairs up-1 / down-1 and up-2 / down-2, respectively. PCR reaction conditions: 95°C, 5min; (95°C, 50s; 60°C, 50s; 72°C, 40s) x 29 cycles; 72°C, 10min; 25°C, 1min. A 657bp upper arm fragment was amplified by the primer pair up-1 / down-1, and a 656bp lower arm fragment was amplified by the primer pair up-2 / down-2.

[0042] The upper and lower arm fragments of the above SSIG_RS25215 gene were ...

Embodiment 2

[0045] Embodiment 2: Transformation of recombinant plasmid

[0046] Using electric shock method or heat shock method, vector pD25215 was used to transform competent cells of Escherichia coli ET12567 without restriction modification, and unmethylated plasmid DNA was extracted from transformants. Transformation of Streptomyces roseospora protoplasts with unmethylated plasmid DNA can significantly increase the transformation efficiency. The original vector pKC1139 without inserting the upper and lower arm fragments of SSIG_RS25215 was used as a control.

[0047] The wild-type Streptomyces roseospora strain NRRL11379 was selected as the starting strain to prepare protoplasts. Transform protoplasts with plasmids pD25215 and pKC1139 extracted from Escherichia coli ET12567, respectively, and spread them on the dried RM14 plates without antibiotics. Aqueous solution, continue culturing at 28°C for 5-7 days, and the grown colony is the transformant.

[0048] Three transformants were...

Embodiment 3

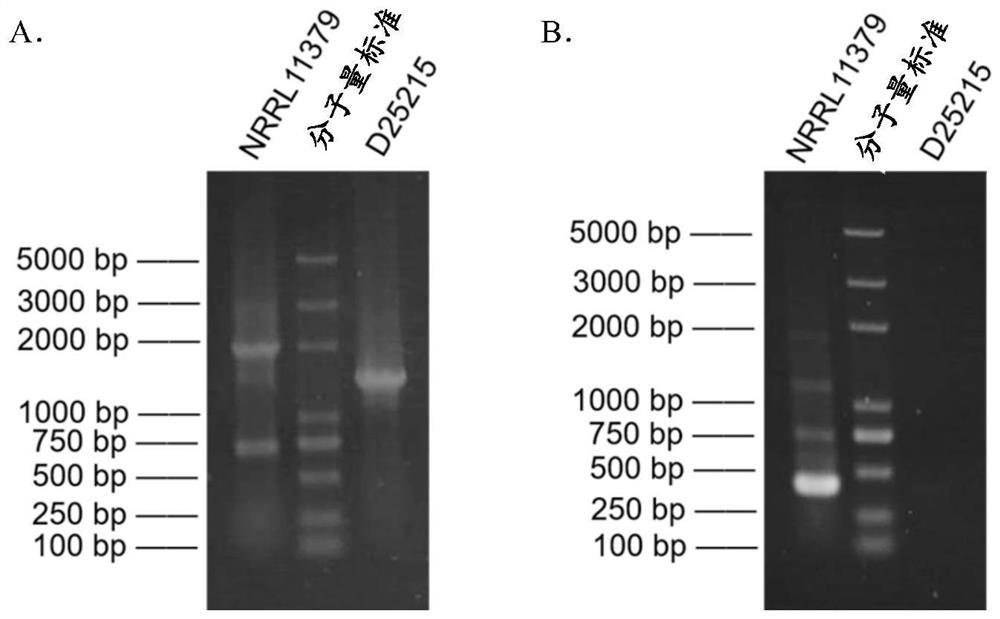

[0049] Embodiment 3: Obtaining of SSIG_RS25215 gene deletion mutant strain

[0050] The above-mentioned spores verified to contain the plasmid pD25215 and the control plasmid pKC1139 were collected respectively, spread on the DA1 plate containing apramycin at a concentration of about 100 spores per culture dish, and cultured at 28°C for 48-72 hours. When the diameter of the colony is about 2 mm (when the aerial hyphae will be formed), the plate is transferred to 39°C for 7 days, and some colonies containing pD25215 appear fan-shaped growth, while the colonies containing pKC1139 no longer grow after being transferred to 39°C. grow.

[0051] This is because the control plasmid pKC1139 is a temperature-sensitive Escherichia coli-Streptomyces shuttle plasmid, which cannot replicate itself when the temperature is higher than 34°C, so that the transformant cannot grow on the DA1 medium containing apramycin; while the plasmid pD25215 The upper arm or lower arm fragment of the SSIG_R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com