Au/Ti3C2Tx modified glassy carbon working electrode-based dopamine electrochemical sensor and preparation method thereof

A technology of working electrode and glassy carbon electrode, which is applied in the field of biosensors, can solve problems such as low catalytic activity, small specific surface area, and poor biocompatibility, and achieve high chemical stability, large specific surface area, and good air tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

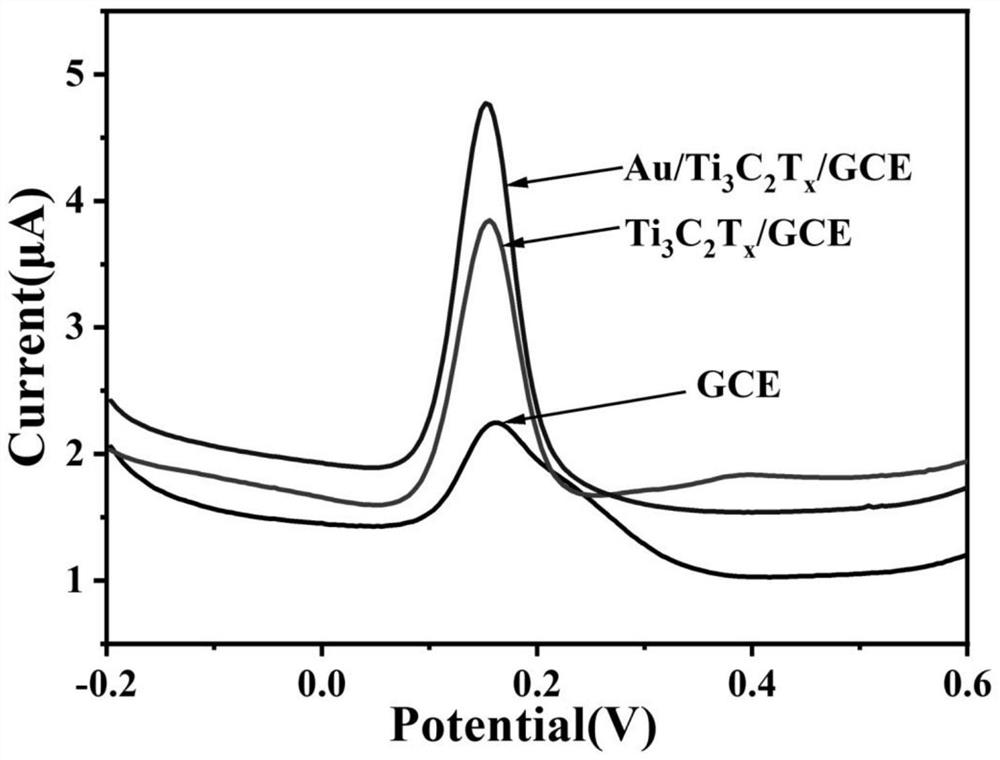

[0037] Using the glassy carbon electrode as the working electrode, the dopamine electrochemical sensor was fabricated based on the three-electrode working system, and the related performance of the sensor was tested. The specific process is as follows:

[0038] 1. Grinding the glassy carbon electrode: Before grinding the glassy carbon electrode, gently wipe the glassy carbon electrode with moistened absorbent cotton to remove dirt and ensure the surface of the electrode is smooth; take 2 mg of polishing powder Al with a particle size of 0.05 μm 2 o 3Put it on the suede, then add 2mL of deionized water dropwise, and stir it evenly with the polishing powder; hold the glassy carbon electrode firmly to ensure that the glassy carbon electrode is always moving vertically in a circular or "8" shape. Rotate clockwise and counterclockwise 100 times until the surface of the glassy carbon electrode appears mirror-like, and rinse with deionized water. Then, using the washed glassy carbon...

Embodiment 2

[0041] to Ti 3 C 2 T x As an electrode modification material modified glassy carbon electrode (GCE), namely Ti 3 C 2 T x / GCE is the working electrode, and the dopamine electrochemical sensor is made, and the manufacturing process is as follows:

[0042] 1. The process of polishing the glassy carbon electrode is the same as that in Example 1.

[0043] 2. Making Ti 3 C 2 T x / GCE working electrode: first prepare Ti 3 C 2 T x nanocomposites.

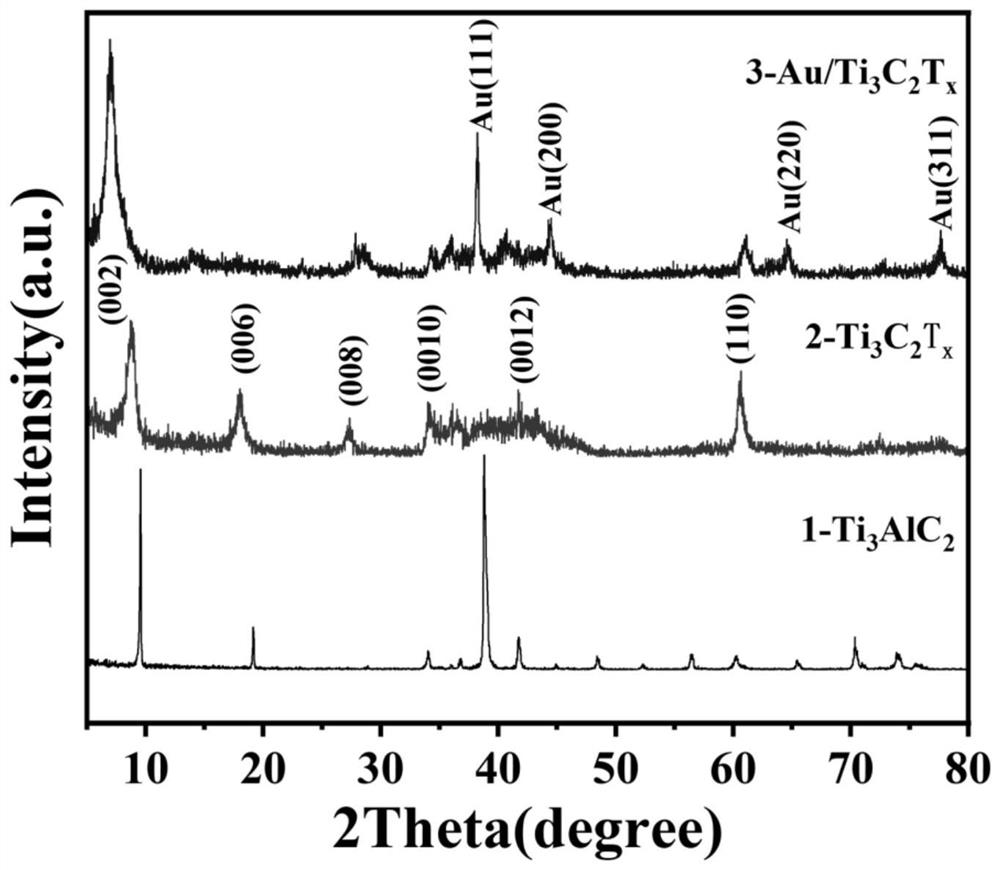

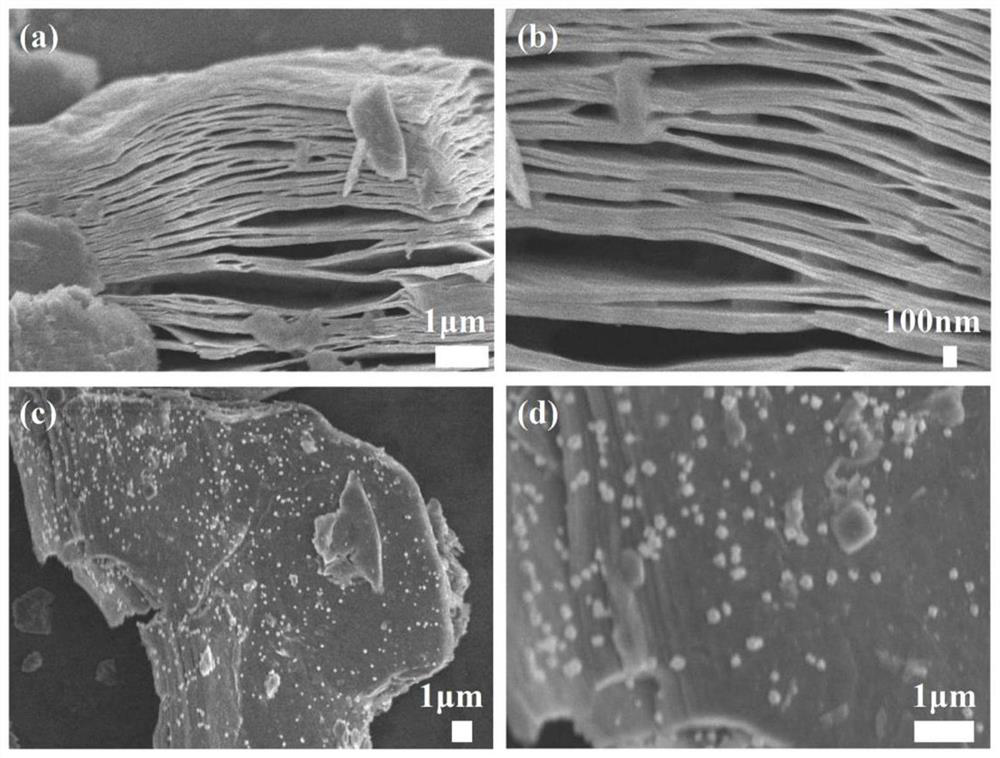

[0044] 2g Ti 3 AlC 2 The powder was slowly added into 40 mL of 40 wt % hydrofluoric acid solution, and reacted with magnetic stirring at 40° C. for 24 h. Then by adding deionized water several times to centrifuge and wash (4000rpm, each 10min), until the pH of the supernatant = 6, the resulting precipitate was freeze-dried to obtain Ti 3 C 2 T x powder.

[0045] to Ti 3 C 2 T x As the electrode modification material, modified on the glassy carbon electrode: take 3mg Ti 3 C 2 T x Add 3 mL of deionized water to the po...

Embodiment 3

[0048] with Au / Ti 3 C 2 T x Modified glassy carbon electrode (GCE) as electrode modification material, namely Au / Ti 3 C 2 T x / GCE is the working electrode, and the dopamine electrochemical sensor is made, and the manufacturing process is as follows:

[0049] 1. The process of polishing the glassy carbon electrode is the same as that in Example 1.

[0050] 2. Making Au / Ti 3 C 2 T x / GCE working electrode: first prepare Au / Ti 3 C 2 T x nanocomposites.

[0051] Weigh 80mg Ti 3 C 2 T x Dissolve the powder in 40mL deionized water and mix well, add 0.4mL, 20mg / mL HAuCl to the mixed solution 4 solution and mix well, slowly add the weighed 0.019mg NaBH 4 , after magnetic stirring for 3 h, the reactants were centrifuged at 12,000 rpm for three times, and finally dried in a vacuum oven at 60°C for 24 h to obtain Au / Ti 3 C 2 T x powder.

[0052] with Au / Ti 3 C 2 T x For the electrode modification material, modify the glassy carbon electrode according to the proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com