Cooling nursing bag with soft texture and long cooling time

A cooling time and soft technology, applied in the field of cooling nursing bag preparation, can solve the problems of gradual temperature gradient, short cooling time, inability to meet physical cooling needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A cooling care bag with soft texture and long cooling time, including the following steps:

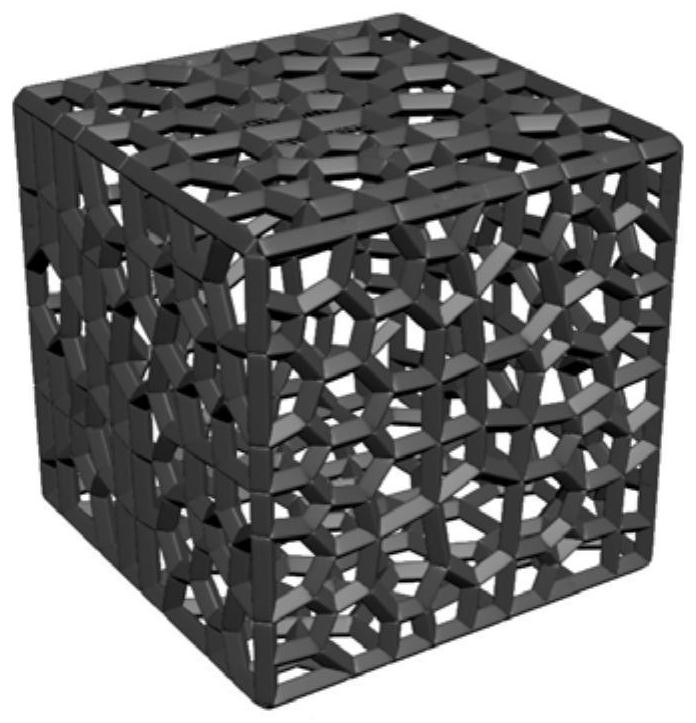

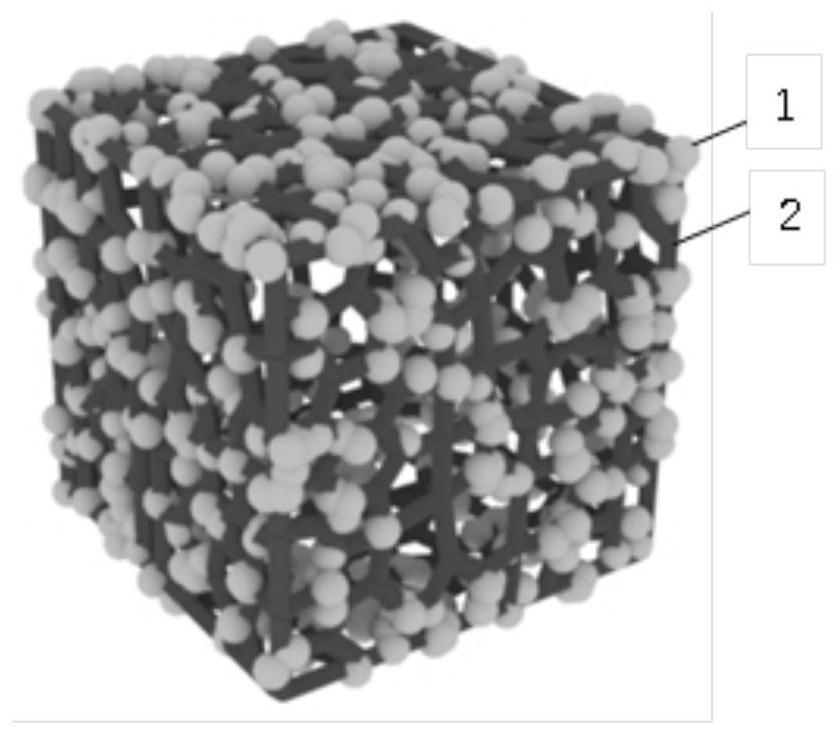

[0031] (1) Methyl methacrylate, monofluorotrichloromethane, alkyl betaine sulfonic acid, triethylenediamine, and dimethylformamide are in a mass ratio of 50%: 2%: 1%: 2%: 45 % uniformly mixed, and polymerized at 80°C for 90 minutes to form porous polymethyl methacrylate through polymerization;

[0032] (2) The water-based polyurethane and ethanol are formed into a uniform solution according to the volume fraction of 40%: 60%, and the porous polymethyl methacrylate obtained in step (1) is immersed in the solution, so that the solution completely submerges the porous polymethacrylate methyl methacrylate, soaking the porous polymethyl methacrylate obtained in step (1) for 24 hours by vacuum impregnation method at room temperature, so that the porous polymethyl methacrylate is filled with the aqueous polyurethane solution;

[0033] (3) Take out the saturated porous polymethyl metha...

Embodiment 2

[0040] A cooling care bag with soft texture and long cooling time, including the following steps:

[0041] (1) Dimethicone, pentane, N-alkyliminodiacetic acid sodium salt, tetramethylbutanediamine and triethylamine are in a mass ratio of 70%: 0.5%: 0.5%: 1%: 28% uniform mixing, polymerizing at 50°C for 200 minutes, forming porous polydimethylsiloxane through polymerization;

[0042](2) A uniform solution of water-based epoxy and diethyl ether is formed according to the volume fraction of 20%: 80%, and the porous polydimethylsiloxane obtained in step (1) is immersed in the solution, so that the solution completely submerges the porous polydimethylsiloxane. Methyl siloxane, using the pressure dipping method to impregnate the porous polydimethylsiloxane obtained in step (1) for 48 hours at room temperature, so that the porous polydimethylsiloxane is filled with the aqueous polyester solution;

[0043] (3) Take out the saturated porous polydimethylsiloxane from the aqueous epoxy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com