Ceramic shell for single-crystal high-temperature alloy blade and preparation method of ceramic shell

A high-temperature alloy, ceramic type technology, applied in the field of investment casting, can solve the problems of increasing the amount of slurry and sand and prolonging the cycle of ceramic shells, and achieves the effect of reducing the amount of consumption, shortening the production cycle, and improving the ease of release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

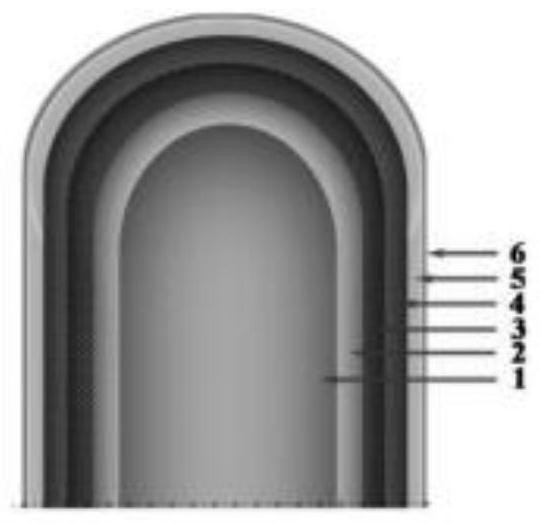

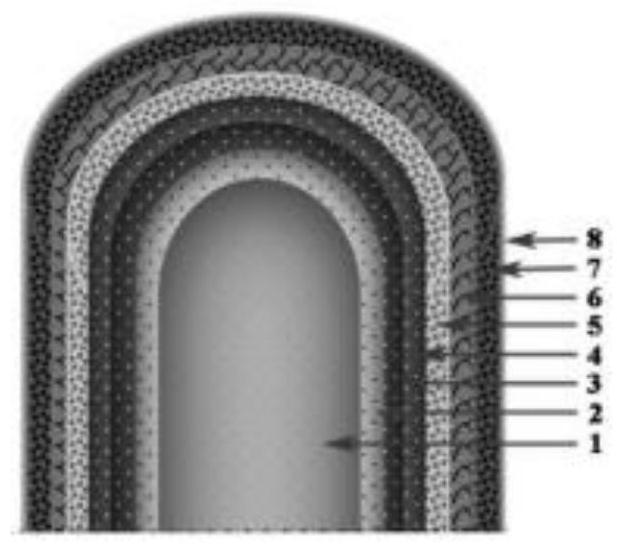

[0035] The invention provides a preparation method of a ceramic shell for a single crystal superalloy blade, comprising the following steps:

[0036] (1) carry out surface layer slurry coating, sanding and drying on the outer surface of the wax mold to obtain the first composite structure after preparing the surface layer;

[0037] (2) on the outer surface of the first composite structure obtained in the step (1), the transition layer slurry coating, sanding and drying are performed to prepare the transition layer to obtain the second composite structure;

[0038] (3) on the outer surface of the second composite structure obtained in the step (2), carry out the back layer slurry coating, sanding and drying to prepare the first back layer to obtain the third composite structure;

[0039] (4) coating the outer surface of the third composite structure obtained in the step (3) with epoxy resin, and then wrapping a layer of carbon fiber tape on the outer surface of the epoxy resin ...

Embodiment 1

[0076] (1) Wax mold pretreatment: decontaminate the pressed wax mold and dry it for later use; the schematic diagram of the wax mold structure is shown in image 3 ,from image 3 It can be seen that the wax model includes five cylinders.

[0077] (2) Preparation of surface layer slurry: use silica sol and 320-mesh EC95 powder (EC95 powder is brown corundum sand made of 95% alumina and 5% silica fused and sintered) to prepare a slurry with a viscosity of 3.2mPa.s The surface layer slurry is ready for use;

[0078] (3) Preparation of surface layer: the surface layer slurry prepared in step (2) is used to coat and sand the surface layer slurry on the outer surface of the pressed wax mold, and then it is placed in the room to dry naturally for 12 hours to obtain the first composite structure. ; The sand in the sand is 70 mesh EC95 powder;

[0079] (4) Configure the transition layer slurry: use silica sol and 320 mesh EC95 powder to prepare a slurry with a viscosity of 3.1 mPa.s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com