Nano molybdenum sulfide and application thereof as efficient adsorbent for uremic toxin

A technology of molybdenum sulfide and nanotechnology, which is applied in the direction of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problems of difficult storage of adsorption materials, low adsorption efficiency, poor biocompatibility, etc., and achieve good biocompatibility and high-efficiency adsorption performance , highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

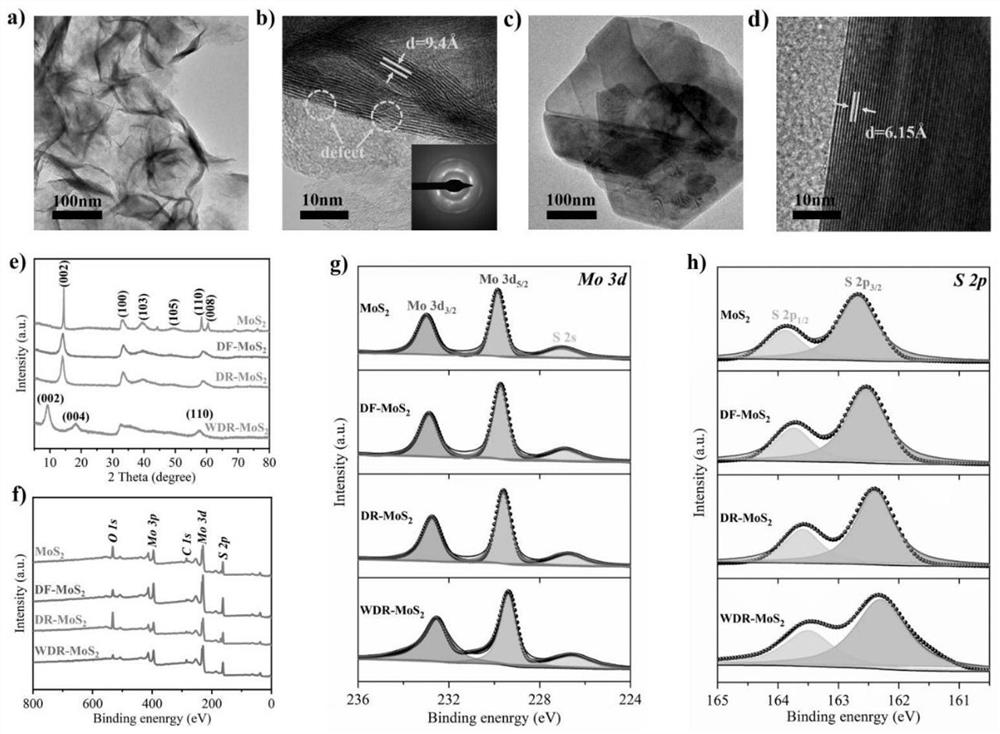

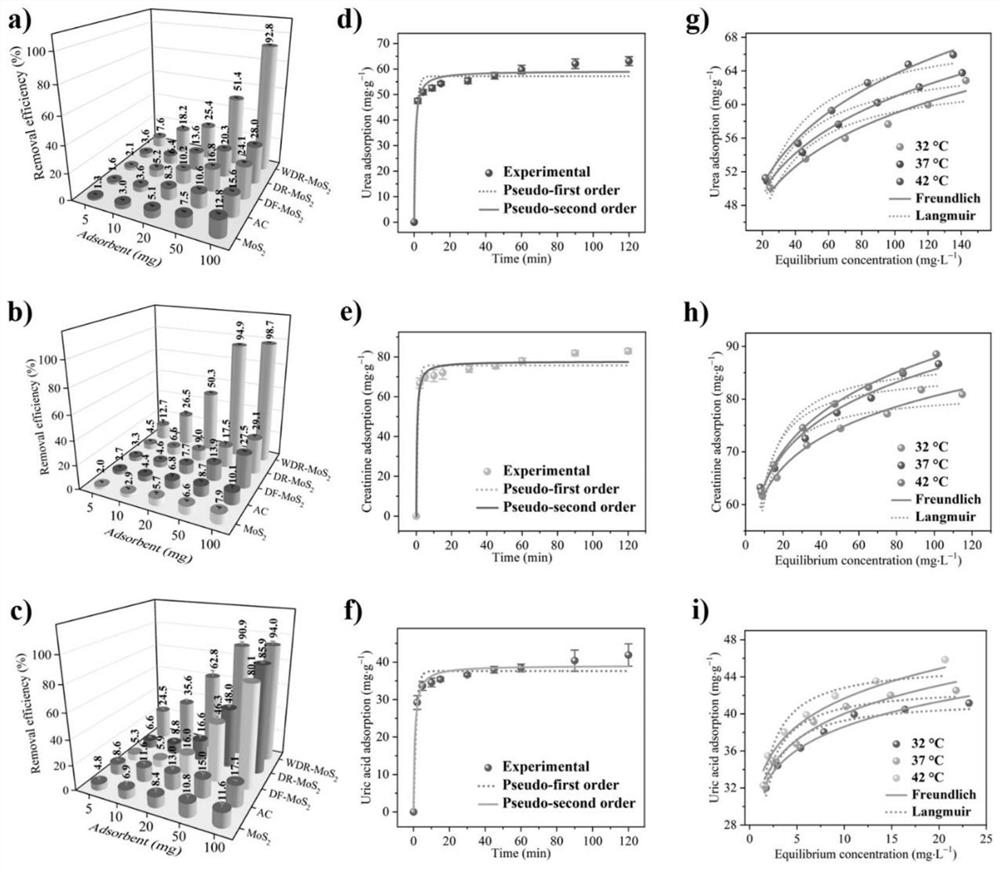

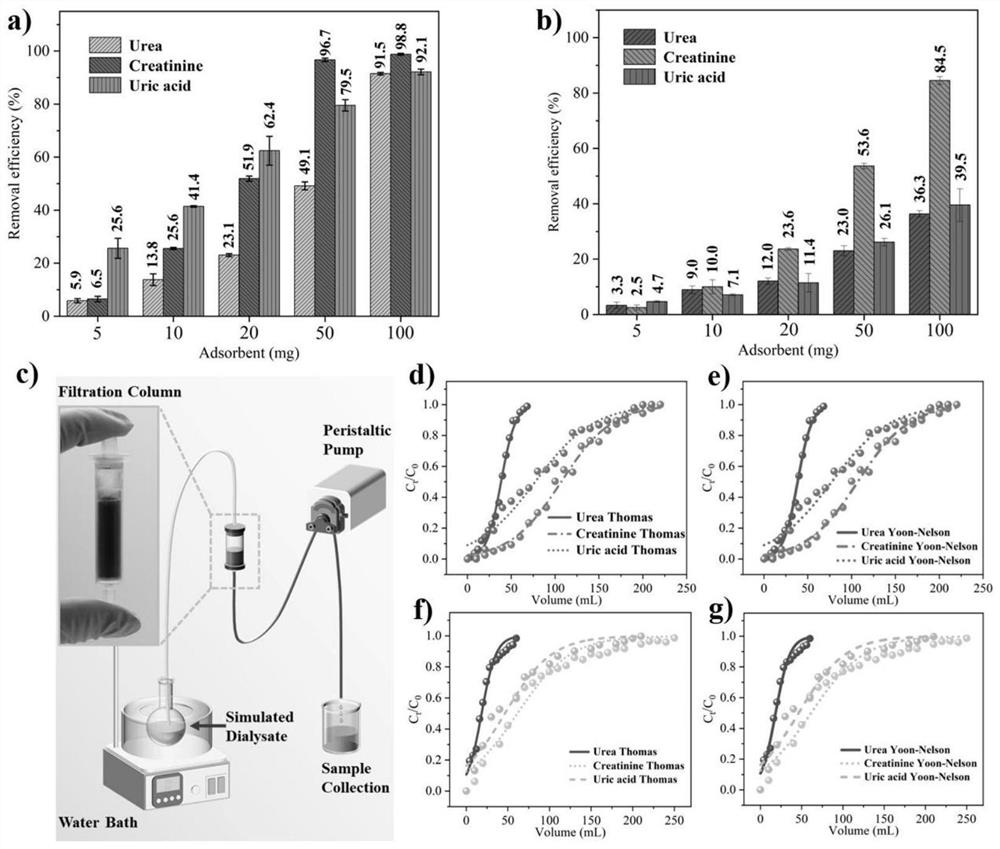

[0024] will (NH 4 ) 6 Mo 7 O 24 ·4H 2 O (1 mmol) and CS (NH 2 ) 2 (30 mmol) was added to 225 mL of distilled water, and the mixture was stirred for 30 minutes and then transferred to a 300 mL polytetrafluoroethylene autoclave, and reacted at 180° C. for 24 hours. The product was washed with ethanol and distilled water, and dried under vacuum at 60°C for 24 hours.

Embodiment 2

[0026] will (NH 4 ) 6 Mo 7 O 24 ·4H 2 O(2mmol) and CS(NH 2 ) 2 (60 mmol) was added to 225 mL of distilled water, the mixture was stirred for 30 minutes, and then transferred to a 300 mL polytetrafluoroethylene autoclave, and reacted at 180° C. for 24 hours. The product was washed with ethanol and distilled water, and dried under vacuum at 60°C for 24 hours.

Embodiment 3

[0028] will (NH 4 ) 6 Mo 7 O 24 ·4H 2 O(3mmol) and CS(NH 2 ) 2 (90 mmol) was added to 225 mL of distilled water, and the mixture was stirred for 30 minutes and then transferred to a 300 mL polytetrafluoroethylene autoclave, and reacted at 180° C. for 24 hours. The product was washed with ethanol and distilled water, and dried under vacuum at 60°C for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com