A kind of iron-doped copper sulfide nanosheet material with abundant defects and its preparation method and application

A technology of iron doping and nanosheets, which is applied in the field of nanomaterials, can solve the problems of slowness and restrict the development of hydrogen production energy technology by electrolysis of water, and achieve the effect of high purity, low production cost and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

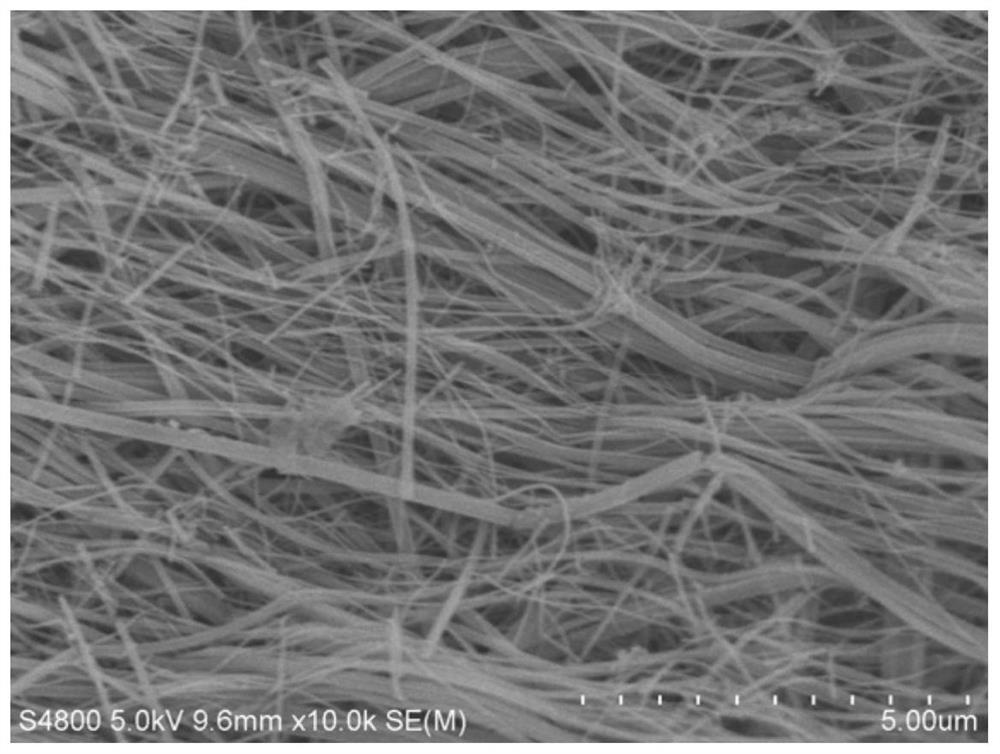

[0041] A method for self-assembling to form an iron-doped copper sulfide (Fe-CuS-0.025) nanosheet material with abundant defects, comprising the following steps:

[0042] S1: Dissolve 2mmol of copper chloride dihydrate in 10ml of absolute ethanol and stir vigorously to dissolve completely to form a uniform copper salt solution; 0.05mmol ferrous chloride tetrahydrate is vigorously stirred in 20mL of ethanol until completely dissolved to form a uniform ferrous salt solution;

[0043] S2: Vigorously stir 4 mmol of thiourea in 10 mL of ethanol until completely dissolved;

[0044] S3: Then, under vigorous stirring, the thiourea solution and the copper salt solution were rapidly mixed and stirred for 15 minutes to obtain a white flocculent intermediate solution;

[0045] S4: Under vigorous stirring, quickly mix the ferrous salt solution with the white flocculent intermediate solution obtained in step S3 and stir for 15 minutes, then transfer to a 60mL reaction kettle, tighten the l...

Embodiment 2

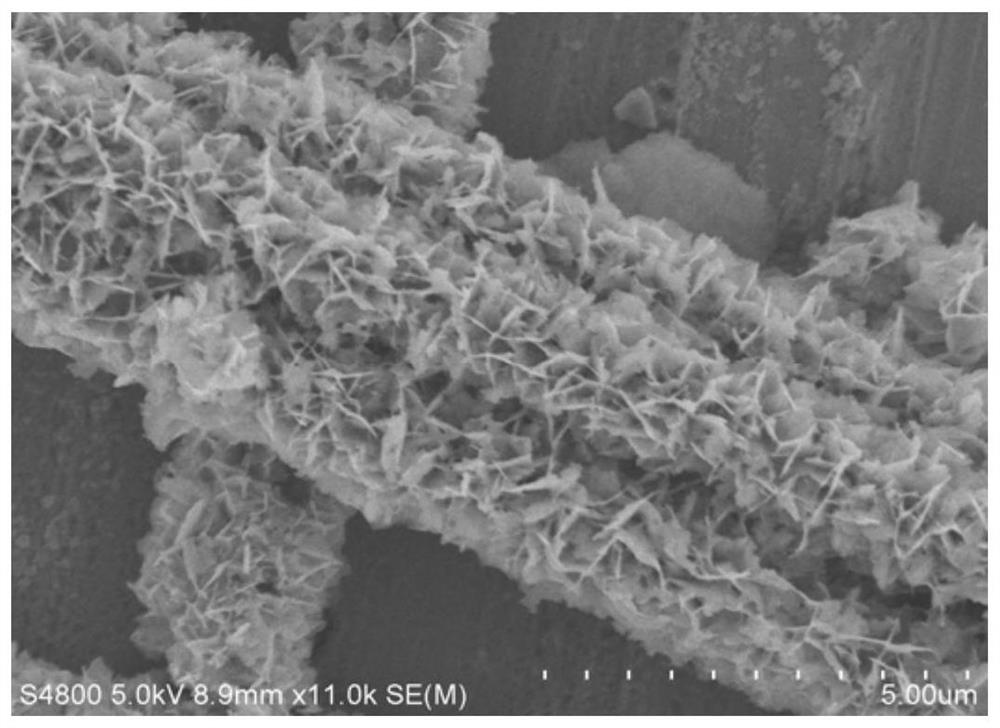

[0048] A method for self-assembling to form an iron-doped sulfur (Fe-CuS-0.033) copper nanosheet material with abundant defects, comprising the following steps:

[0049]S1: Dissolve 2mmol of copper chloride dihydrate in 10ml of absolute ethanol and stir vigorously to dissolve completely to form a uniform copper salt solution; 0.067mmol ferrous chloride tetrahydrate is vigorously stirred in 20mL of ethanol until completely dissolved to form a uniform ferrous salt solution;

[0050] S2: Vigorously stir 4 mmol of thiourea in 10 mL of ethanol until completely dissolved;

[0051] S3: Then, under vigorous stirring, the thiourea solution and the copper salt solution were rapidly mixed and stirred for 15 minutes to obtain a white flocculent intermediate solution;

[0052] S4: Under vigorous stirring, quickly mix the ferrous salt solution with the white flocculent intermediate solution obtained in step S3 and stir for 15 minutes, then transfer to a 60mL reaction kettle, tighten the li...

Embodiment 3

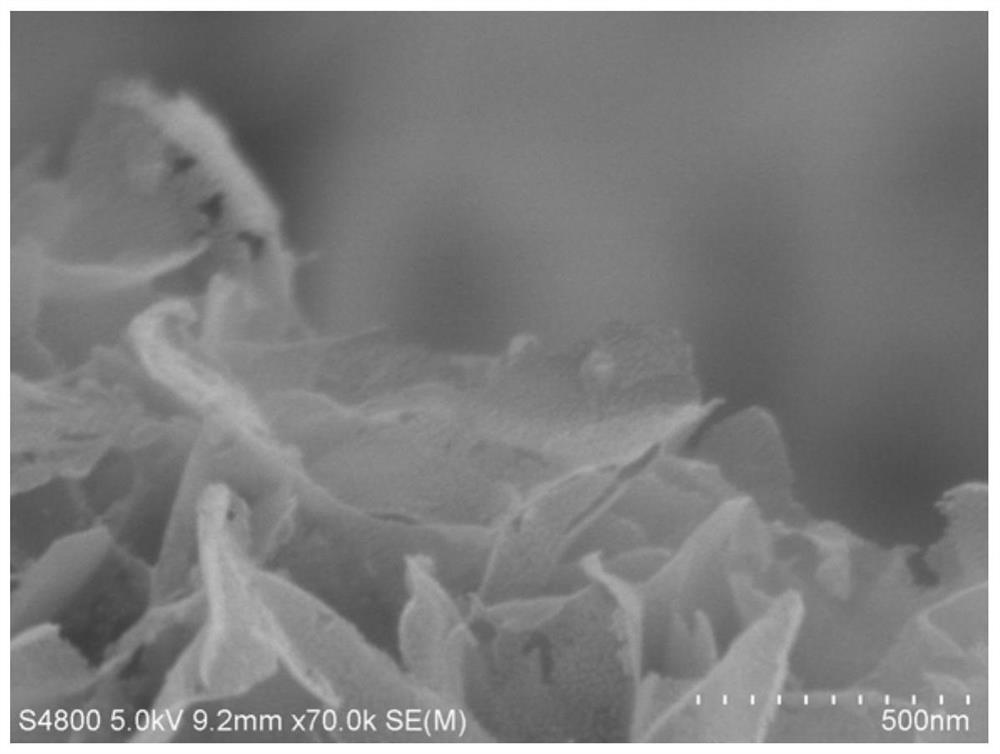

[0055] A method for self-assembling to form an iron-doped sulfur (Fe-CuS-0.05) copper nanosheet material with abundant defects, comprising the following steps:

[0056] S1: Dissolve 2mmol of copper chloride dihydrate in 10ml of absolute ethanol and stir vigorously to dissolve completely to form a uniform copper salt solution; 0.1mmol ferrous chloride tetrahydrate is vigorously stirred in 20mL of ethanol until completely dissolved to form a uniform ferrous salt solution;

[0057] S2: Vigorously stir 4 mmol of thiourea in 10 mL of ethanol until completely dissolved;

[0058] S3: Then, under vigorous stirring, the thiourea solution and the copper salt solution were rapidly mixed and stirred for 15 minutes to obtain a white flocculent intermediate solution;

[0059] S4: Under vigorous stirring, quickly mix the ferrous salt solution with the white flocculent intermediate solution obtained in step S3 and stir for 15 minutes, then transfer to a 60mL reaction kettle, tighten the lid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com