Formula, processing technology and use method of plastic master batch with long-acting insect repelling and preventing effects

A technology for plastic masterbatch and insect control, applied in the field of plastic masterbatch, can solve the problems of short validity period, easy shedding of drugs, and safety, etc., and achieve the effect of long validity period, extended shelf life, and prevention of product damage and aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment proposes a plastic masterbatch formulation with long-term repelling and insect repellent effects, including component A and component B;

[0060] In parts by mass, component A includes 12 parts of cypermethrin, 5 parts of antioxidant, 70 parts of LLDPE, and 0.3 part of dispersant;

[0061] In parts by mass, component B includes 10 parts of aluminosilicate, 10 parts of strong polar dispersant, 65 parts of LLDPE, and 15 parts of piperonyl butoxide.

[0062] Wherein, the antioxidant includes pentaerythritol ester, the dispersant includes pe wax, and the strong polar dispersant includes montan wax or polyester wax.

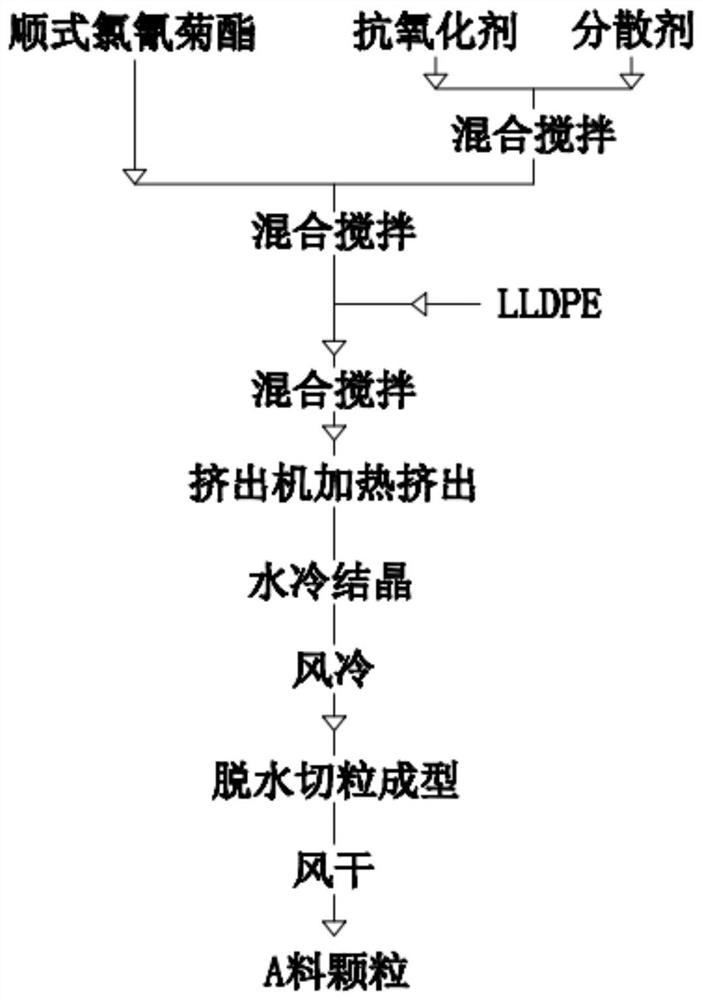

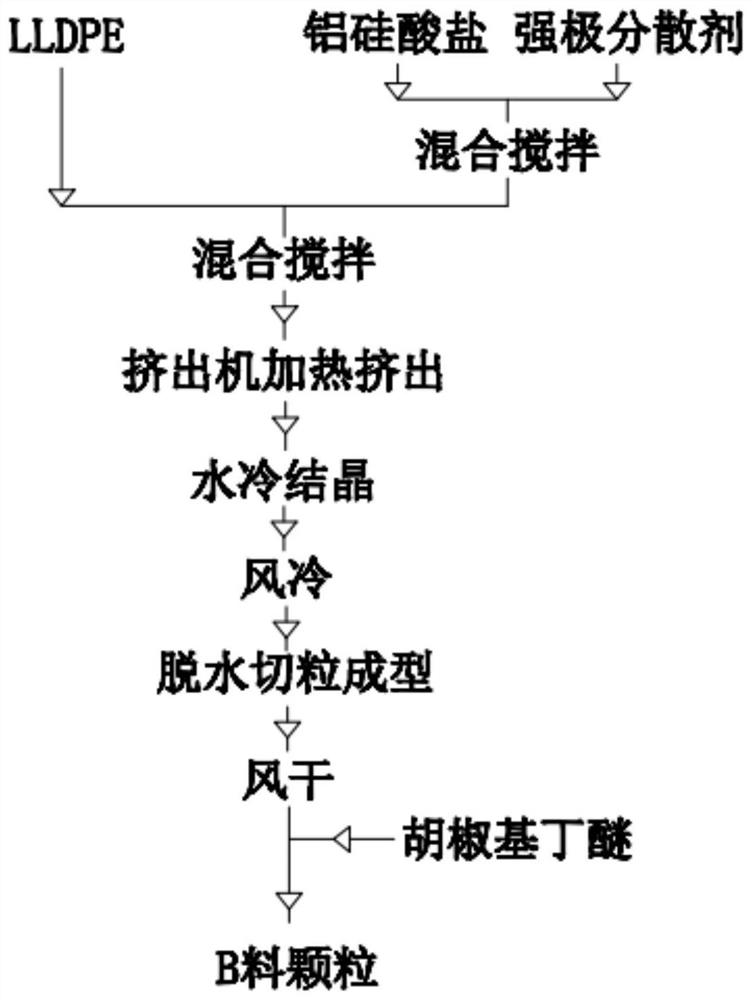

[0063] The processing technology of plastic masterbatch with long-term repelling and insect repellent effects includes the following steps:

[0064] The preparation steps of A material particles are as follows:

[0065] (a) firstly, 5 mass parts of antioxidants and 0.3 mass parts of dispersants are mixed and stirred;

[0066] (b) then add 12 ...

Embodiment 2

[0080] The present invention firstly proposes a formula of plastic masterbatch with long-term repelling and insect repellent effects, including component A and component B;

[0081] In parts by mass, component A includes 20 parts of cypermethrin, 10 parts of antioxidant, 85 parts of LLDPE, and 1.5 parts of dispersant;

[0082] In parts by mass, component B includes 25 parts of aluminosilicate, 30 parts of strong polar dispersant, 80 parts of LLDPE, and 30 parts of piperonyl butoxide.

[0083] Wherein, the antioxidant includes pentaerythritol ester, the dispersant includes pe wax, and the strong polar dispersant includes montan wax or polyester wax.

[0084] The processing technology of plastic masterbatch with long-term repelling and insect repellent effects includes the following steps:

[0085] The preparation steps of A material particles are as follows:

[0086] (a) mixing and stirring 10 parts by mass of antioxidant and 1.5 parts by mass of dispersant;

[0087] (b) the...

Embodiment 3

[0101] The present invention firstly proposes a formula of plastic masterbatch with long-term repelling and insect repellent effects, including component A and component B;

[0102] In parts by mass, component A includes 16 parts of cypermethrin, 8 parts of antioxidant, 78 parts of LLDPE, and 1 part of dispersant;

[0103] In parts by mass, component B includes 18 parts of aluminosilicate, 20 parts of strong polar dispersant, 72 parts of LLDPE, and 22 parts of piperonyl butoxide.

[0104] Wherein, the antioxidant includes pentaerythritol ester, the dispersant includes pe wax, and the strong polar dispersant includes montan wax or polyester wax.

[0105] The processing technology of plastic masterbatch with long-term repelling and insect repellent effects includes the following steps:

[0106] The preparation steps of A material particles are as follows:

[0107] (a) firstly, 8 parts by mass of antioxidant and 1 part by mass of dispersant are mixed and stirred;

[0108] (b) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com