Environment-friendly gloss paint suitable for automatic pencil coloring machine and preparation method of environment-friendly gloss paint

An automatic coloring and environmental protection technology, applied in the direction of coating, polyurea/polyurethane coating, etc., to prevent volatilization and protect the factory environment

Pending Publication Date: 2022-06-03

浙江鸿星文具有限公司

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Such as Chinese patent CN101240145B "single-component classification skin texture paint" by mixing elastic resin, feel filler, dispersion aid, matte powder to obtain pencil skin texture paint coating; such as Chinese patent CN10702294A "a kind of water-based matte wooden pole "Elastomer pencil and its preparation method" uses water-based polyurethane matting resin as the main material, and adds various additives to speed up the curing and film-forming speed of pencil paint. paint standard

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

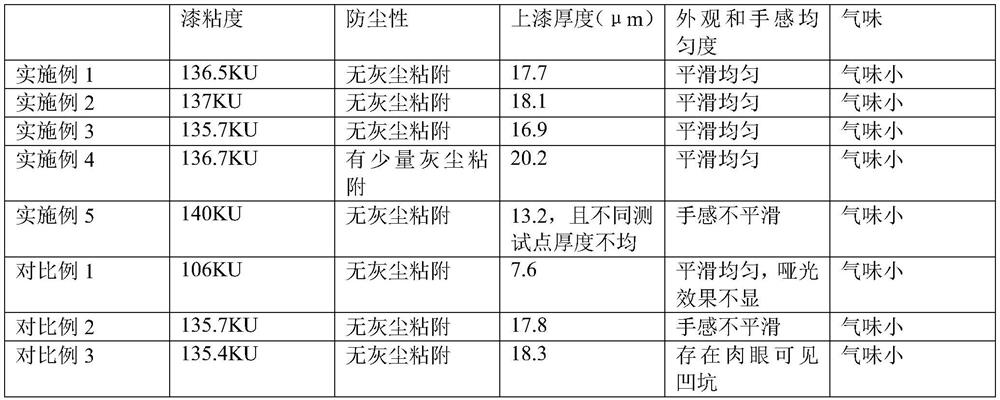

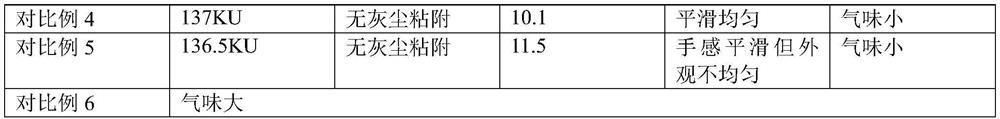

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of pencil paint, and discloses environment-friendly gloss paint suitable for an automatic pencil coloring machine and a preparation method of the environment-friendly gloss paint. Comprising the following components in parts by mass: 80 to 90 parts of water-based resin, 0.2 to 1 part of a defoaming agent, 0.1 to 0.5 part of a dispersing agent, 3.5 to 7 parts of a coalescing agent, 2 to 7 parts of extinction powder, 0.1 to 0.2 part of a sterilizing agent, 0.1 to 0.2 part of an antibacterial agent, 1 to 4 parts of a thickening agent, 0.05 to 0.1 part of a neutralizing agent, 0.5 to 3 parts of a hand feeling agent and 0.1 to 0.5 part of a flatting agent. The water-based resin forms an elastic and glossy component of the varnish and can reduce the volatility of the coalescing agent, the defoaming agent prevents a finished product from generating pits, the dispersing agent contributes to uniform mixing of all the components, the matting powder realizes a matte effect, the thickening agent adjusts the viscosity of the varnish in a varnish cylinder, and the flatting agent promotes the fluidity of the varnish and contributes to smoothness of the coating process; the gloss paint reaches the paint flowability standard of an automatic painting machine, the automatically painted pencils have uniform and full matte texture and certain dustproof performance, the volatility of the paint is small, and ambient air pollution is prevented.

Description

technical field [0001] The invention relates to the technical field of pencil paint, in particular to an environment-friendly gloss paint suitable for an automatic pencil coloring machine and a preparation method thereof. Background technique [0002] The automation of pencil painting is an inevitable trend in the production of modern pencil industry. The most commonly used automatic painting and coloring method is to inject pencils into the paint tank, then shoot and dry, and the pencils are painted in the paint tank. Process control is the key to the quality control of pencil painting. The pencil is quickly painted through the paint tank. There is an inner rubber ring in the paint tank for the pencil to pass through. It is used to control the amount of paint. The viscosity and shear force of the paint directly affect the pencil. The adhesion time with the paint will then affect the thickness and quality of the pencil paint. Therefore, it is necessary to design a paint that...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D133/00C09D175/04C09D7/20

CPCC09D133/00C09D175/04C09D7/20C08L75/04C08L33/00

Inventor 叶明上王林春刘辉

Owner 浙江鸿星文具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com