Double-sided antistatic LR film, assembly and display device

A thin-film component and antistatic technology, which is applied in conductive coatings, optical components, identification devices, etc., can solve the problems of poor adhesion of thin-film coatings, poor coating uniformity, high requirements for equipment and process conditions, and achieve the anti-static value of the film layer Stable, permanent antistatic performance, excellent effect of coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

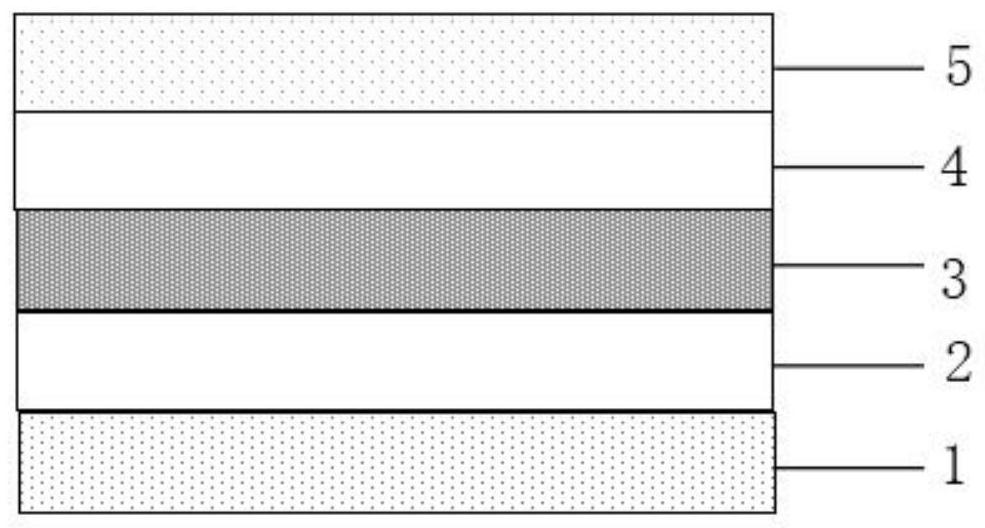

[0026] The bifacial antistatic LR film in the present embodiment, comprising sequentially disposing of the first LR layer 1, the first antistatic coating 2, the substrate 3, the second antistatic coating 4 and the second LR layer 5, wherein the first LR layer 1 and the second LR layer 5 are equally thick, and formed by the anti-reflective coating fluid. The anti-reflective coating solution comprises, by weight: 15 parts of polyurethane acrylic resin; 2-Hydroxy-2-methyl-1-phenyl-1-propanone 1 part; 10 parts of magnesium fluoride particles with a particle size of 30 nm; 1 part of vinyl distearylamide; Solvent methyl ethyl ketone 40 parts.

Embodiment 12

[0028] The bifacial antistatic LR film in the present embodiment, comprising sequentially disposing of the first LR layer 1, the first antistatic coating 2, the substrate 3, the second antistatic coating 4 and the second LR layer 5, wherein the first LR layer 1 and the second LR layer 5 are equally thick, and formed by the anti-reflective coating fluid. The anti-reflective coating solution comprises, by weight: polyurethane acrylic resin 20 parts; 1-Hydroxy-cyclohexyl-phenylmethanone 2 parts; 10 parts of magnesium fluoride particles, 10 parts of polymethyl methacrylate (PMMA) particles with a particle size of 20 nm; Monoglyceride stearate 2 parts; Solvent propylene glycol methyl ether 50 parts.

Embodiment 13

[0030]The bifacial antistatic LR film in the present embodiment, comprising sequentially disposing of the first LR layer 1, the first antistatic coating 2, the substrate 3, the second antistatic coating 4 and the second LR layer 5, wherein the first LR layer 1 and the second LR layer 5 are equally thick, and formed by the anti-reflective coating fluid. The anti-reflective coating solution comprises, by weight: polyurethane acrylic resin 25 parts; Ethyl 4-dimethylamino-benzoate 3 parts; Alumina particles with a mass ratio of 1:2 with a particle size of 150 nm and magnesium fluoride particles with a particle size of 20-150 nm total 15 parts; 3 parts of glyceryl tristearate; Solvent methyl isobutyl ketone 60 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com