Composite refined production method and system for camellia oleosa seed oil

A compound essence and production method technology, which is applied in the production of oil/fat, refining of oil/fat, production of fat, etc., can solve the complex and backward production process, reduce the quality of camellia seed oil, and cannot realize the refined production of camellia oil. control and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

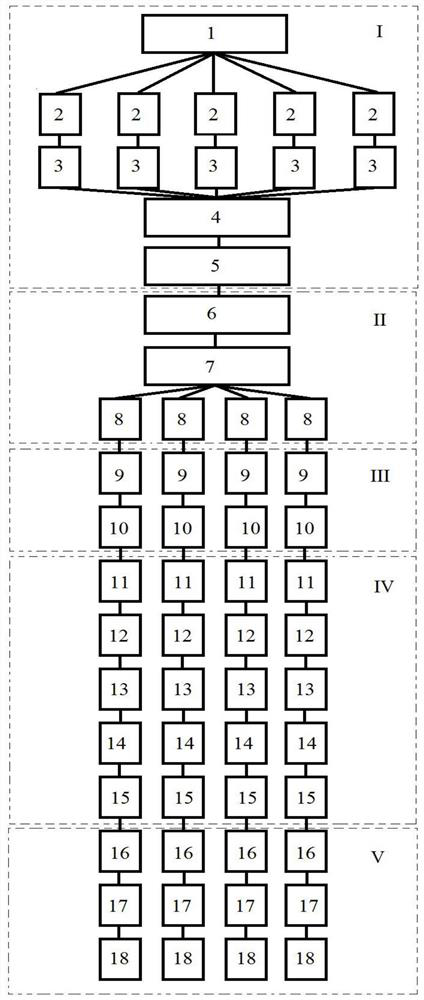

Method used

Image

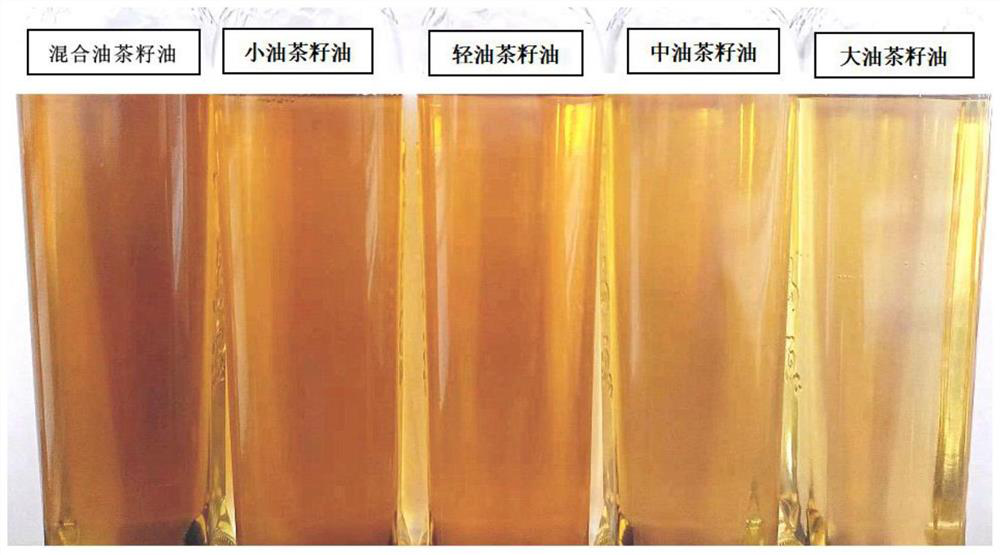

Examples

Embodiment 1

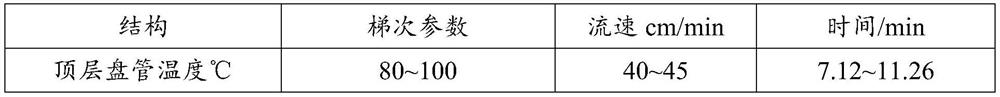

[0116] A compound refined production method of camellia oleifera seed oil, including the following process steps:

[0117] 1. Differentiated and accurate fresh seed drying technology:

[0118] (1) After the tea oleifera fruit is picked and collected by the base, the elastic mesh of different calibers is installed through the grading and screening equipment of camellia oleifera (the pore size of the elastic mesh is 3.1cm, 4.7cm, 6.3cm, 7.9cm, 9.5cm, respectively), and the refined grading screening of camellia oleifera fruit assembly line is carried out, and the camellia oleifera fruit is differently graded, and the primary tea oil fruit, the secondary tea oil fruit, the third-grade tea oil fruit, the fourth-grade tea oil fruit and the fifth-grade tea oil fruit are obtained; Batch sampling was carried out for each grade of Camellia oleifera fruit, and the average fruit diameter, average hull thickness, average moisture content and average quality of each grade of Camellia oleifera f...

Embodiment 2

[0155] A compound refined production method of camellia oleifera seed oil, including the following process steps:

[0156] 1. Differentiated and accurate fresh seed drying technology:

[0157] (1) After the tea oleifera fruit is picked and collected by the base, the elastic mesh of different calibers is installed through the grading and screening equipment of camellia oleifera (the pore size of the elastic mesh is 3.1cm, 4.7cm, 6.3cm, 7.9cm, 9.5cm, respectively), and the refined grading screening of camellia oleifera fruit assembly line is carried out, and the camellia oleifera fruit is differently graded, and the primary tea oil fruit, the secondary tea oil fruit, the third-grade tea oil fruit, the fourth-grade tea oil fruit and the fifth-grade tea oil fruit are obtained; Batch sampling was carried out for each grade of Camellia oleifera fruit, and the average fruit diameter, average hull thickness, average moisture content and average quality of each grade of Camellia oleifera f...

Embodiment 3

[0196]A compound refined production method of camellia oleifera seed oil, including the following process steps:

[0197] 1. Differentiated and accurate fresh seed drying technology:

[0198] (1) After the tea oleifera fruit is picked and collected by the base, the elastic mesh of different calibers is installed through the grading and screening equipment of camellia oleifera (the pore size of the elastic mesh is 3.1cm, 4.7cm, 6.3cm, 7.9cm, 9.5cm, respectively), and the refined grading screening of camellia oleifera fruit assembly line is carried out, and the camellia oleifera fruit is differently graded, and the primary tea oil fruit, the secondary tea oil fruit, the third-grade tea oil fruit, the fourth-grade tea oil fruit and the fifth-grade tea oil fruit are obtained; Batch sampling was carried out for each grade of Camellia oleifera fruit, and the average fruit diameter, average hull thickness, average moisture content and average quality of each grade of Camellia oleifera fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com