Mn (VO3) 2/V2O5 catalyst as well as preparation method and application thereof

A catalyst and carbonization technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of short life and low activity of vanadium-based catalysts, and achieve high activity Increased sites, excellent ability to catalyze the degradation of chlorobenzene organic compounds, and high catalytic efficiency

Active Publication Date: 2022-06-10

JIANGSU UNIV OF TECH

View PDF12 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006]

In order to solve the technical problems of low activity and short life of existing vanadium-based catalysts, a Mn(VO

3

)

2

/ V

2

o

5

Catalyst and its preparation method and application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

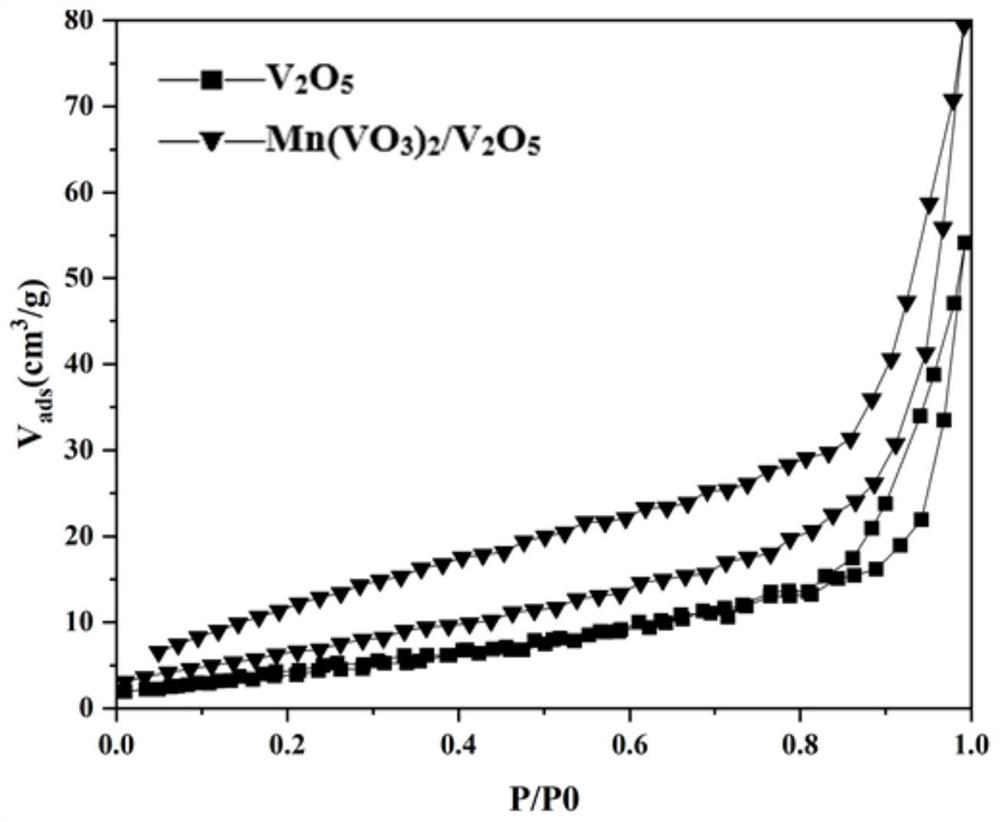

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

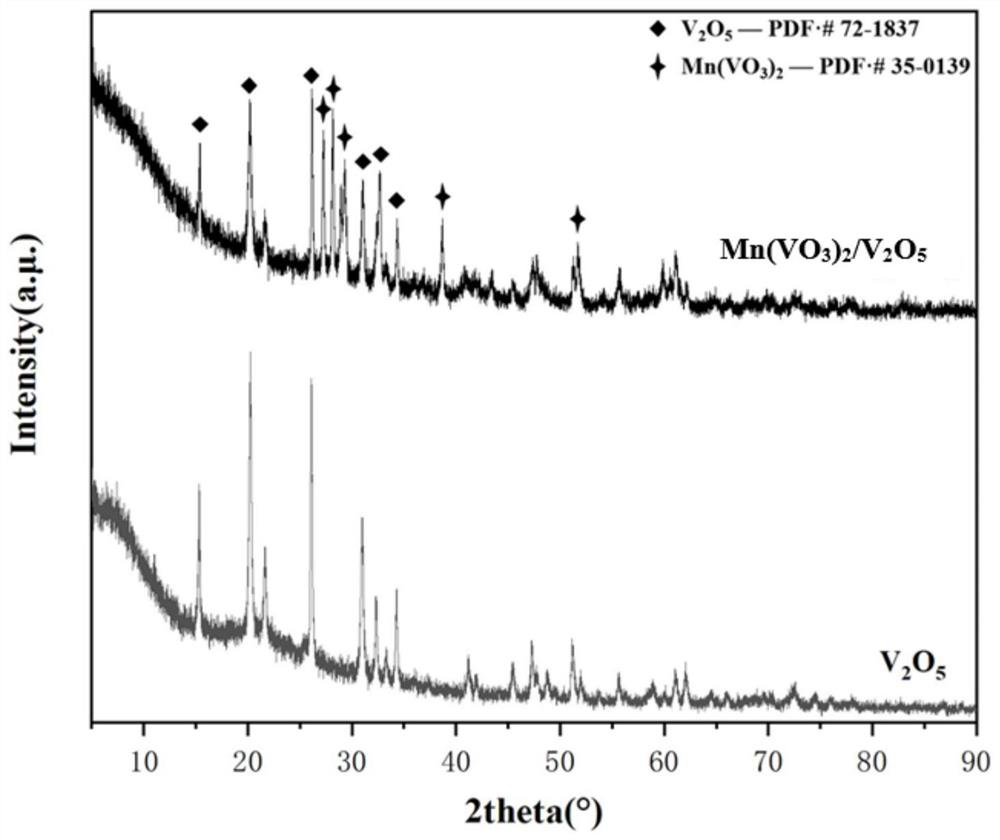

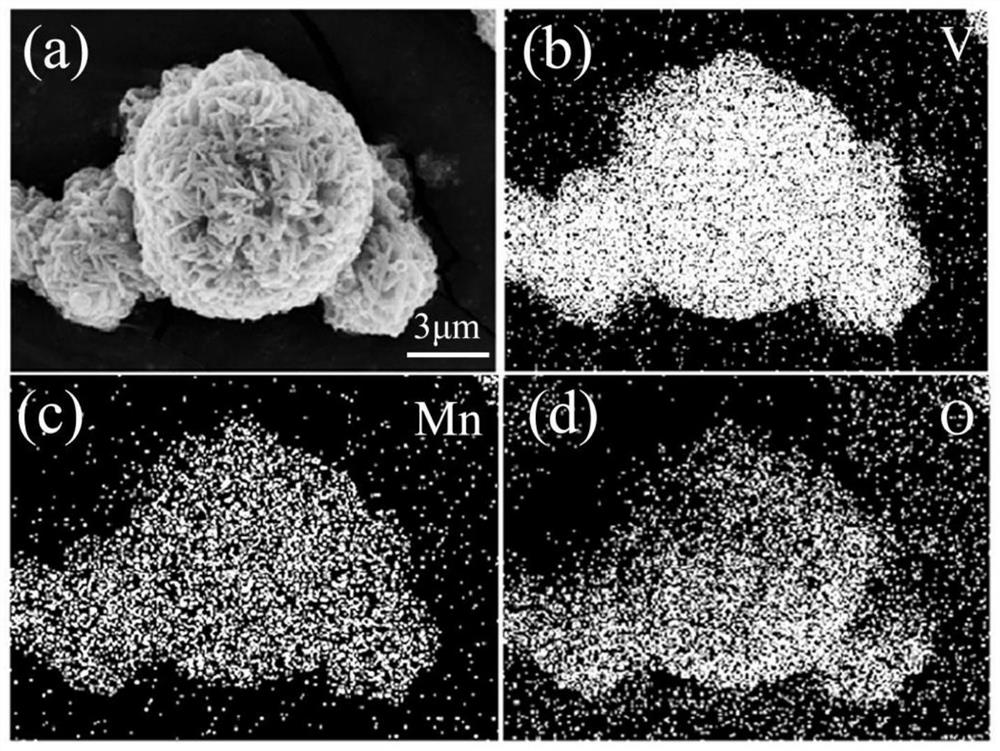

The invention relates to a Mn (VO3) 2 / V2O5 catalyst and a preparation method and application thereof, and the preparation method comprises the following steps: (1) dissolving a vanadium salt in a polyhydroxy compound aqueous solution, adding a manganese salt, uniformly mixing to obtain a precursor solution, then carrying out a hydrothermal reaction, and collecting a precipitation product after the reaction is finished; and (2) cleaning the precipitation product for multiple times, drying, carrying out pre-oxidation treatment in an oxidation atmosphere, and then carrying out carbonization treatment in a nitrogen atmosphere to prepare the Mn (VO3) 2 / V2O5 catalyst. The second metal is doped in the vanadium-based catalyst to form the doped composite catalyst, the doped composite catalyst has good catalytic oxidation activity, the catalytic oxidation efficiency of the catalyst on CBs can be improved, and the reaction temperature can be reduced.

Description

A Mn(VO 3 ) 2 / V 2 O 5 Catalyst and its preparation method and application technical field The present invention relates to inorganic catalyst technical field, be specifically related to a kind of Mn(VO 3 ) 2 / V 2 O 5 Catalyst and its preparation law and application. Background technique Chlorobenzene volatile organic compounds (CBs) are harmful to the environment and human health, and excessive discharge can cause secondary organic gas Increases in sols (SOA), peroxyacetyl nitrate (PAN) and tropospheric ozone, which are also major contributors to the greenhouse gas effect Contributor. As a result, relevant regulations on CBs emissions have become progressively improved and more stringent, developing a high-performance, low-cost The current CBs removal technology has urgently become the main problem that scholars need to overcome. Generally the treatment method for CBs is catalytic combustion method, and this method is in the presen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J23/34B01J23/22B01J35/02B01D53/86B01D53/70B01J35/00

CPCB01J23/34B01J23/22B01D53/8662B01J35/50Y02A50/20

Inventor 傅一枭胡雅欣董若羽秦恒飞陈朕楠房静玲周建斌刘维桥

Owner JIANGSU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com