Heat-resistant ceramic coating, surface coating and preparation method

A technology of ceramic coatings and surface coatings, applied in coatings, fireproof coatings, etc., to achieve the effects of reducing the difference in thermal expansion and deformation, good resistance to hot air aging, strong adhesion and heat aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0053] Comparative example 3

[0054] Comparative example 4

[0055] Comparative example 5

preparation example 2

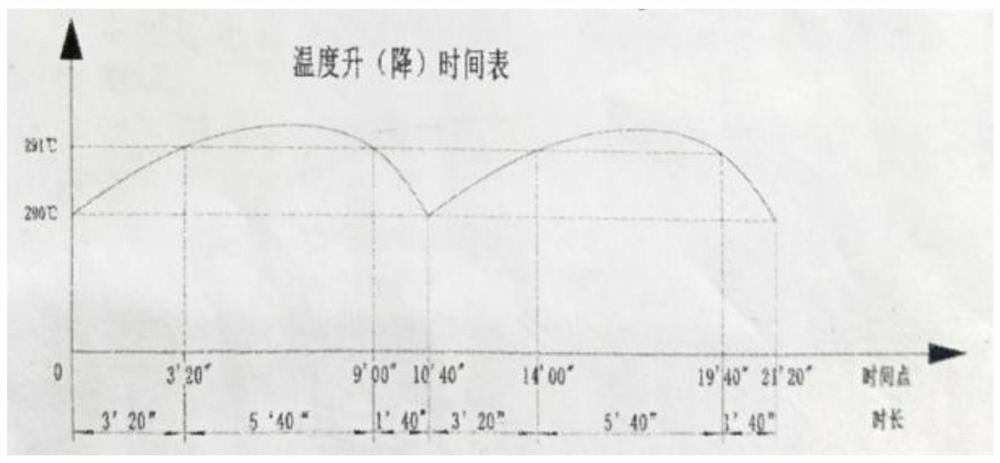

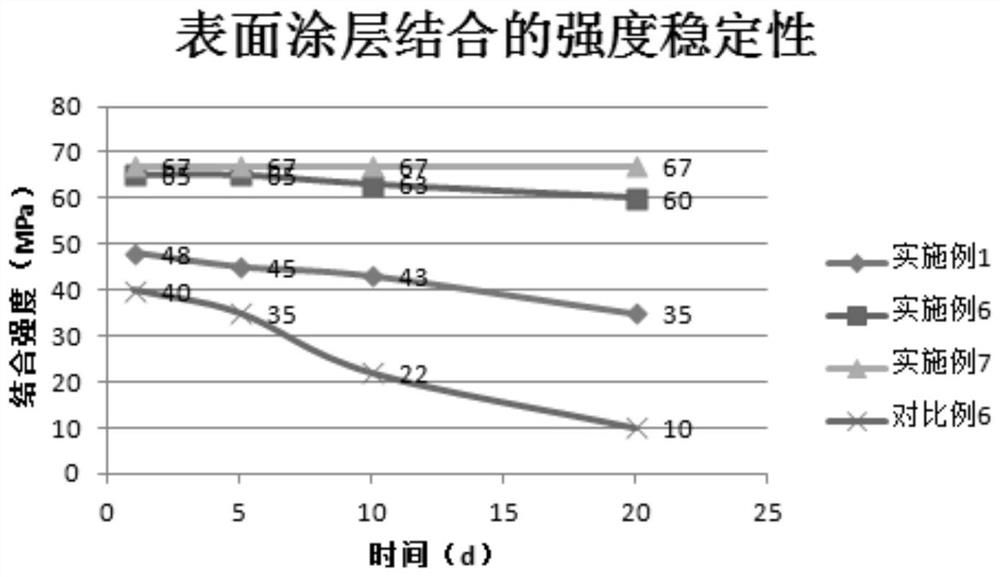

[0057] performance test

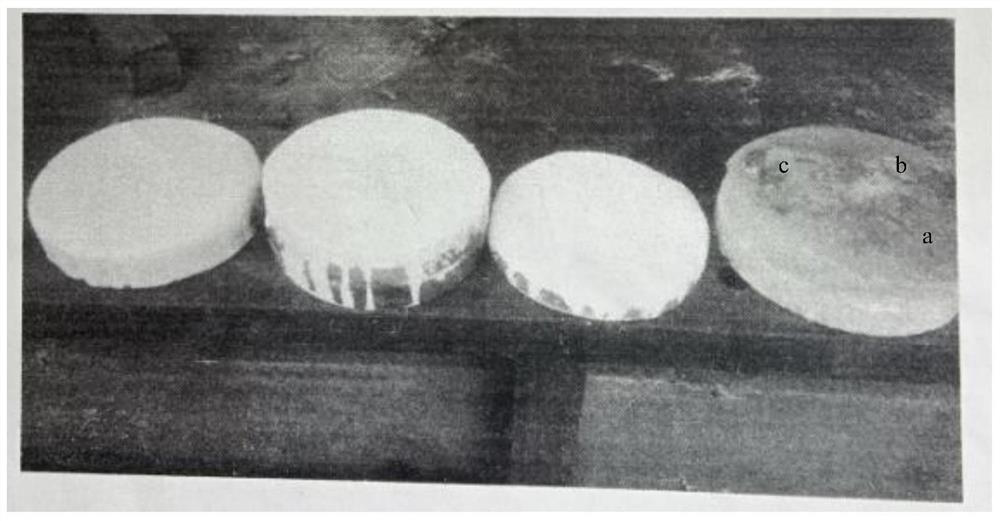

[0058] In conjunction with Example 1, Example 5 and Example 6, it can be seen that the thermal barrier coating in Example 1 is 8 mm, and it is sprayed in 5 times; the thermal barrier coating in Example 5 is only 2 mm, and it is divided into two times Spraying; the heat-insulating coating in comparative example 6 is 8mm, one-time spraying; Adopt the test piece heat insulation temperature difference that the technology of embodiment 6 makes is less than the test piece heat insulation temperature difference that embodiment 1 makes, rate of temperature rise Slower than the heating rate of the sample made in Example 1, the thermal conductivity is greater than that of the sample made in Example 1.

preparation example 3

[0060] In combination with Example 1 and Comparative Examples 2, 3, and 4, it can be seen that no carbon fiber, ZrO 2 With silicone putty powder, but the weight of the insulation layer mixture remains the same, the other two materials are used to replace the unadded substances, but the lack of any one of these materials will affect the synergistic effect of the three substances, therefore, adopt The samples prepared by the processes of Comparative Examples 2, 3, and 4 are smaller in insulation temperature difference, faster in temperature rise rate, poor in erosion resistance, and larger in thermal conductivity than those prepared in the process of Example 1.

[0061] In conjunction with Example 1 and Comparative Example 5, it can be seen that in the preparation method of Comparative Example 5, the thermal insulation layer was not sprayed, and the heat insulation temperature difference of the sample prepared by the preparation method of Comparative Example 5 was small, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com