Silicon carbide wafer wax pasting method and auxiliary wax pasting device

A silicon carbide crystal and silicon carbide technology, applied in the field of silicon carbide wafer waxing methods and auxiliary waxing devices, can solve the problems of unfavorable wafer waxing yield, residual wax layer bubbles, and increased enterprise costs, etc., to achieve the elimination of bubbles, The effect of improving yield rate and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

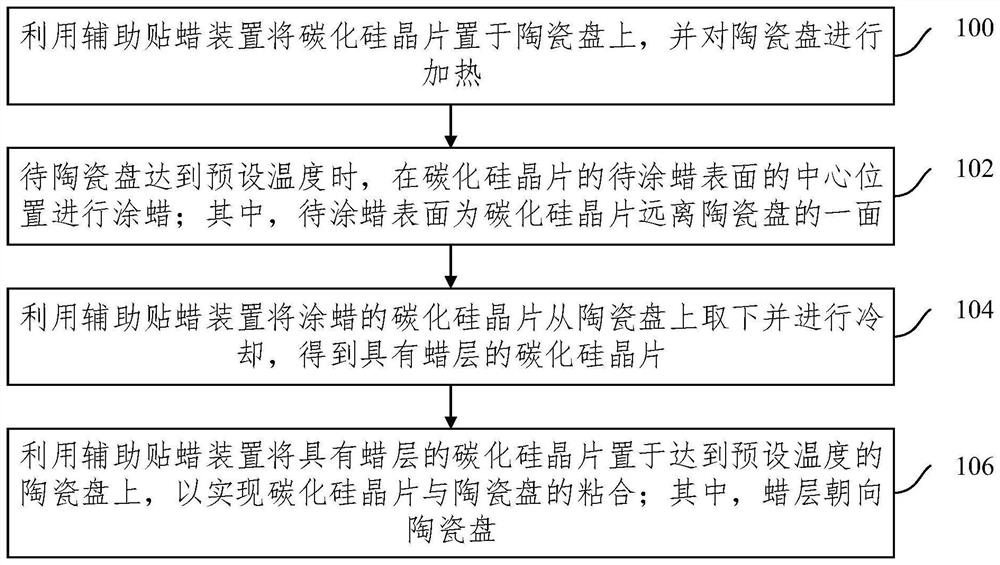

[0083] A method for manually applying wax to a silicon carbide wafer with a size of 4 inches, the method comprising:

[0084] Step (1): place the 4-inch silicon carbide wafer on the auxiliary wax sticking device with the surface to be waxed facing upward, and then use the tray (made of iron) of the auxiliary wax sticking device to place the silicon carbide wafer on the ceramic plate Heating, the preset temperature of the ceramic plate is 100 ℃;

[0085] Step (2): when the preset temperature of the ceramic disc reaches 100°C, the silicon carbide wafer is preheated, and the alcohol-soluble solid bonding wax is used to coat the center of the upper surface of the silicon carbide wafer with wax, and the wax coating area is: A circle with a diameter of 3cm;

[0086] Step (3): use an auxiliary wax sticking device to remove the wax-coated silicon carbide wafer from the ceramic plate in step (2), and re-cool the wax layer to solidify at room temperature (25° C.);

[0087] Step (4): M...

Embodiment 2

[0091] Embodiment 2 is basically the same as Embodiment 1, except that:

[0092] Using silicon carbide wafers with a size of 6 inches; the tray of the auxiliary wax sticking device is made of aluminum;

[0093] The preset temperature of the ceramic plate is 120° C.; in step (2), a temperature-resistant solid bonding wax is used, and the wax-coated area is a circle with a diameter of 4 cm; in step (5), the continuous vibration of the vibration table after the wax layer is spread is completed The time is 40s.

Embodiment 3

[0095] Embodiment 3 is basically the same as Embodiment 1, except that:

[0096] 2-inch silicon carbide wafer is used; the tray of the auxiliary wax sticking device is made of copper-iron alloy;

[0097] The preset temperature of the ceramic plate is 110° C.; in step (2), a high-viscosity solid bonding wax is used, and the wax-coated area is a circle with a diameter of 1 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com