Reaction system and process for preparing acetic acid through methanol carbonylation

A methanol carbonylation and reaction system technology, applied in the field of acetic acid preparation, can solve the problems of serious corrosion of equipment, low product purity, difficult product separation, etc., and achieve the effect of less equipment cost

Pending Publication Date: 2022-06-21

CHANGZHOU INST OF DALIAN UNIV OF TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] For this reason, the present invention provides a kind of reaction system and technique for preparing acetic acid by carbonylation of methanol, in order to overcome the presence of cocatalyst iodide in the prior art will affect equipment Serious corrosion is caused, and at the same time, a large amount of water in the system of preparing acetic acid by methanol carbonylation makes it difficult to separate the product, resulting in the problem of low product purity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

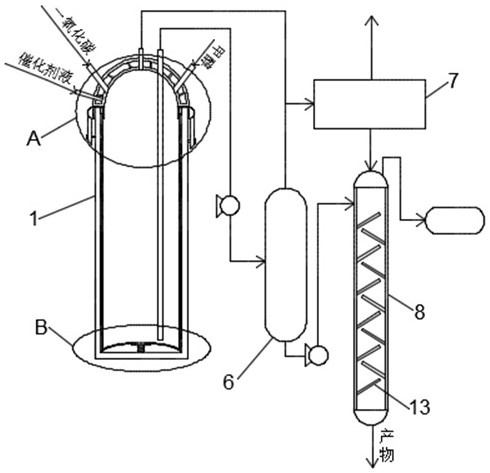

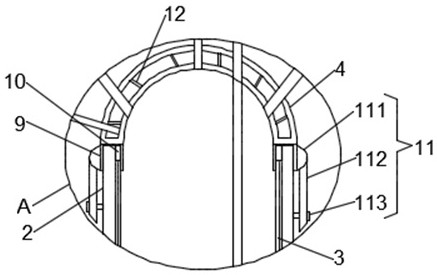

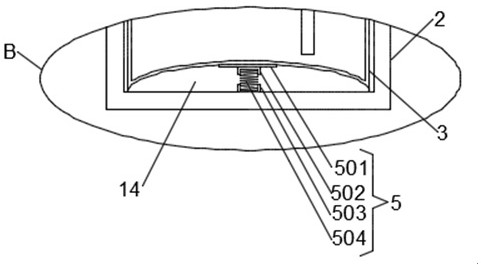

The invention relates to a reaction system and process for preparing acetic acid through methanol carbonylation. The reaction system comprises a reaction container, a container shell, a container inner container and the like. A reaction container is arranged to be of a structure combining a container shell and a container inner container, the reaction container comprises the container shell, the container inner container and a container sealing cover, the container inner container is located in the container shell, the inner wall of the container inner container replaces the container shell to make contact with reactants, and the container sealing cover is used for sealing the open end of the reaction container. The side wall of the container inner container is coated with the anti-corrosion coating, the container inner container can replace the container shell to make contact with reactants, and therefore the purpose that the whole reaction container does not need to be replaced can be achieved only by periodically replacing the container inner container, and the equipment cost is effectively reduced.

Description

technical field [0001] The invention relates to the technical field of acetic acid preparation, in particular to a reaction system and process for preparing acetic acid by carbonylation of methanol. Background technique [0003] Acetic acid is an important basic organic chemical raw material. The main raw materials such as chloroacetic acid, vinyl acetate monomer, polyvinyl alcohol, terephthalic acid, acetate, cellulose acetate and metal acetate are all synthesized from acetic acid. , Acetic acid is widely used in many aspects such as pesticides, medicines, dyes, adhesives and organic solvents. [0004] As a widely used important chemical raw material, the synthesis methods of acetic acid mainly include fermentation of carbohydrates, oxidation of naphtha or n-butane, oxidation of ethylene or acetaldehyde, and carbonylation of methanol, among which methanol carbonylation Accounting for 60% of the current production of acetic acid in the world, the methanol carbonylation me...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C51/12C07C53/08B01D3/06B01J19/00

CPCC07C51/12B01J19/0053B01D3/06C07C53/08

Inventor 刘旭超

Owner CHANGZHOU INST OF DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com