High-glucose-resistant lactic acid production strain and application thereof in D-lactic acid production

A technology of lactic acid and lactate dehydrogenase, applied in the field of microorganisms, can solve problems such as increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

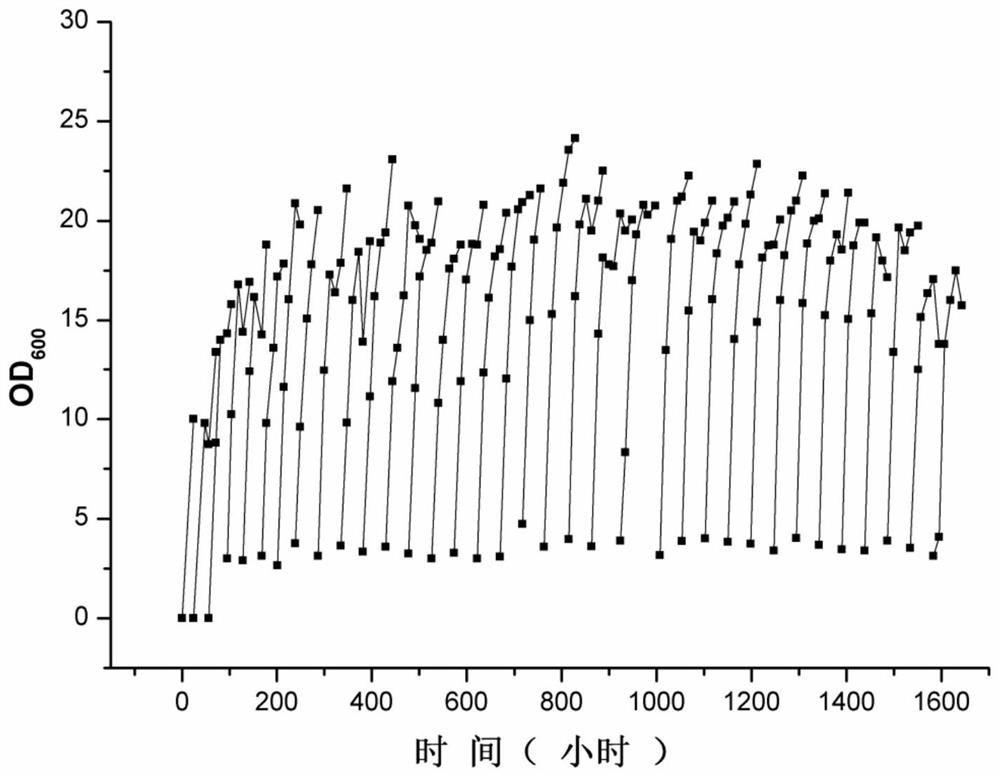

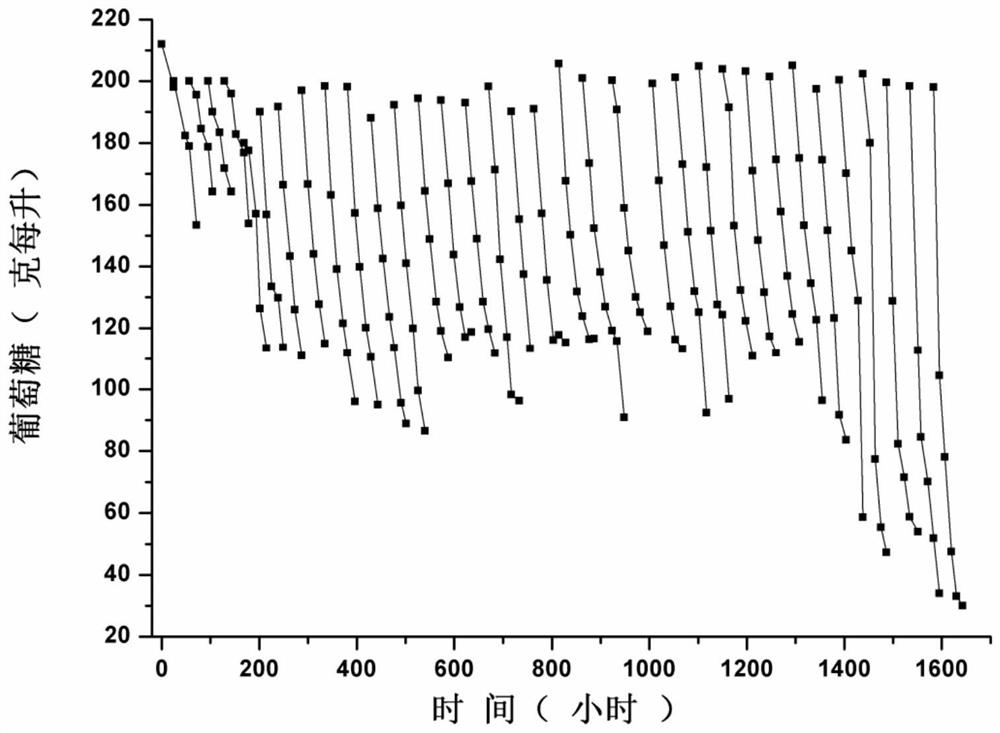

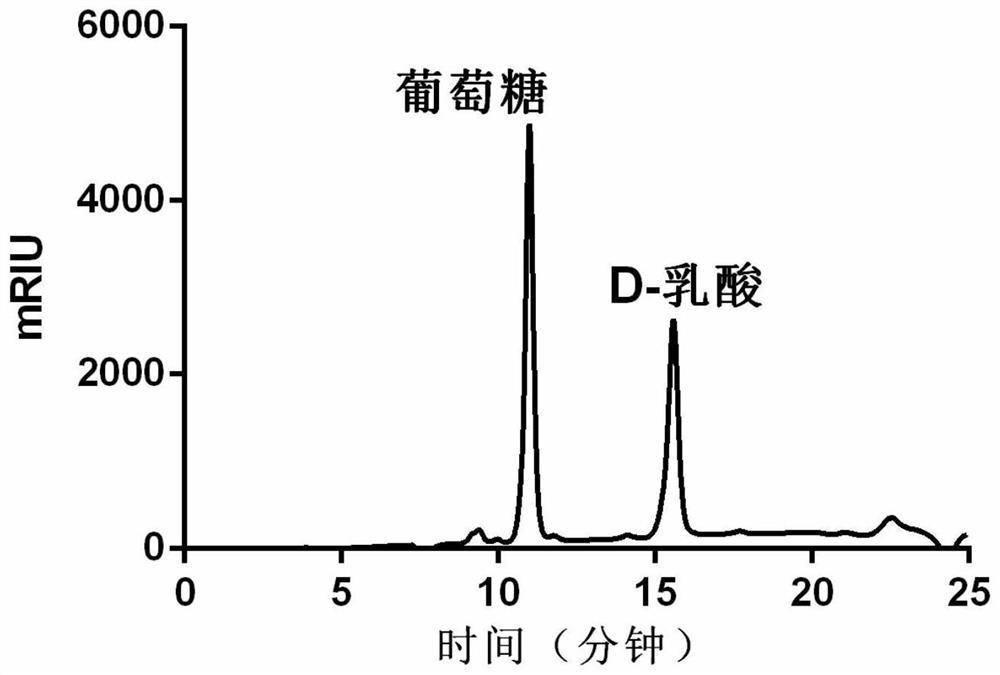

[0053] Embodiment 1, the acquisition of Bacillus coagulans (Bacillus coagulans) G35 and G35-LjLDH and identification of fermentation characteristics

[0054] In this example, Bacillus coagulans (Bacillus coagulans) D-DSM1 was used as the starting strain, and the atmospheric pressure room temperature plasma (ARTP) mutagenesis technology was used in combination with the adaptive evolution technology to screen and obtain a strain that can tolerate high concentrations of initial sugar (200 gram per liter of initial sugar), in low yeast (less than 1 gram per liter) culture medium producing D-lactic acid strain G35, its D-lactic acid production can reach 134 grams per liter of fermentation broth. details as follows:

[0055] 1. ARTP mutagenesis

[0056] 1.1 Mutagenesis process

[0057] Bacillus coagulans (Bacillus coagulans) D-DSM1 was activated with 513 liquid medium (containing glucose 50g / L, yeast powder 10g / L and neutralizing agent 30g / L) for 12 hours, and streaked 513 solid m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com