Submicro gradient hard alloy with cubic phase removed on surface layer and preparation method

A cemented carbide and cubic phase technology, which is applied in the field of cemented carbide materials, can solve the problems of decreasing the wettability of the cemented carbide phase and the binder, increasing the pores of the gradient cemented carbide, hindering sintering and densification, etc., so as to reduce the porosity rate, reducing decarburization problems, promoting strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] According to the present invention, a second aspect is to provide a method for preparing a submicron gradient cemented carbide with a surface layer decubic phase described in the first aspect, the method comprising:

[0066] Step 1, mixing ball mill.

[0067] In step 1, the raw material of the mixture includes Ti(C x , N 1-x ) powder, (W y , Ti 1-y ) C powder, TaC powder and WC powder.

[0068] According to the present invention, the Ti(C x , N 1-x ) powder, (W y , Ti 1-y ) The weight percent content and particle size of C powder, TaC powder and WC powder are preferably the same as the weight percent content and particle size of each substance described in the first aspect.

[0069] According to the present invention, the ball milling process has a direct effect on the cemented carbide.

[0070] In step 1, the weight ratio of pellets is 2-20:1, preferably 5-15:1, more preferably 10:1.

[0071] According to the present invention, the ball loading amount is dete...

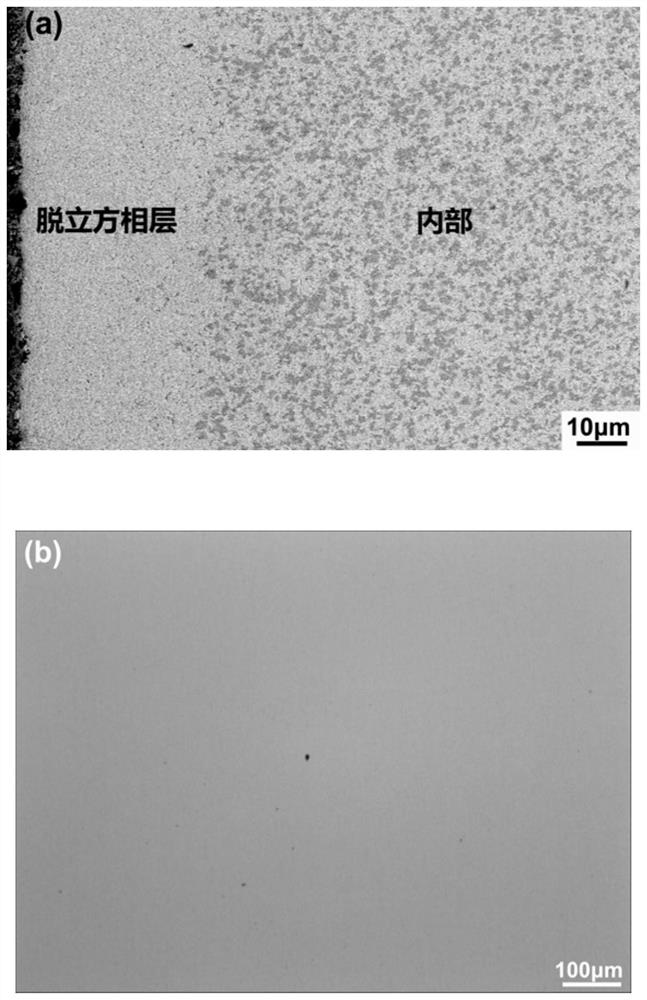

Embodiment 1

[0128] Preparation of Submicrograded Cemented Carbide with Surface Decubic Phase

[0129]Weigh the raw materials by weight to prepare the sub-micro gradient cemented carbide with decubic phase on the surface layer, in which Co with an average particle size of 1.10μm accounts for 9.2%, and Ti(C) with an average particle size of 1.38μm 0.5 ,N 0.5 ) accounted for 3.9% with a particle size of 2.80μm (W 0.23 ,Ti 0.77 )C accounted for 5.3%, TaC with a particle size of 1.28 μm accounted for 1%, W with a particle size of 2.00 μm accounted for 3.34%, and the rest was WC with a particle size of 0.65 μm. The atomic ratio of (Ti+Ta) to N in the total composition of the raw material was 3.54:1.

[0130] First, WC powder, Ti (C 0.5 ,N 0.5 ) powder, (W 0.23 ,Ti 0.77 ) C powder and TaC powder were added to a stirring ball mill for mixing. The grinding balls were WC-6wt% Co cemented carbide balls of Φ6mm, and the weight ratio of the balls was 10:1, and the grinding was carried out at a ...

Embodiment 2

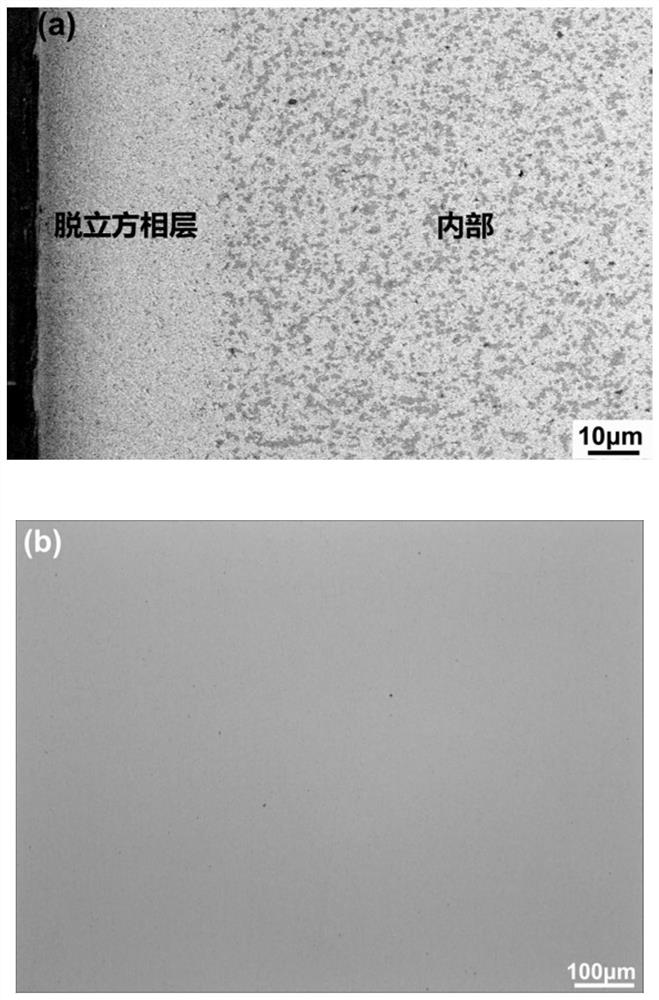

[0138] The method for preparing the submicron gradient cemented carbide with decubic phase on the surface layer in this example is the same as that in Example 1, except that TaC is not added, and the atomic ratio of Ti to N in the total composition of the raw material is 3.38:1.

[0139] The obtained graded cemented carbide has a decubic surface layer thickness of about 37.2 μm and an average WC grain size of 0.63 μm. The SEM image of the microstructure is as follows figure 2 As shown in (a), the porosity is A02B00, and the metallographic structure is as follows figure 2 (b).

[0140] The prepared sub-micro gradient cemented carbide has a density of 99.4%, a transverse fracture strength of 2028.44MPa, and a hardness (Hv30) of 1798.1MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Transverse breaking strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com