Beneficiation method for high-sulfur copper-zinc ore by using sodium humate

A technology of sodium humate and beneficiation method, applied in chemical instruments and methods, flotation, wet separation and other directions, can solve the problems of low recovery rate of copper and zinc, no value recovery, unsatisfactory inhibition effect, etc. The effect of low chemical cost, stable flotation technical indicators, and stable concentrate recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

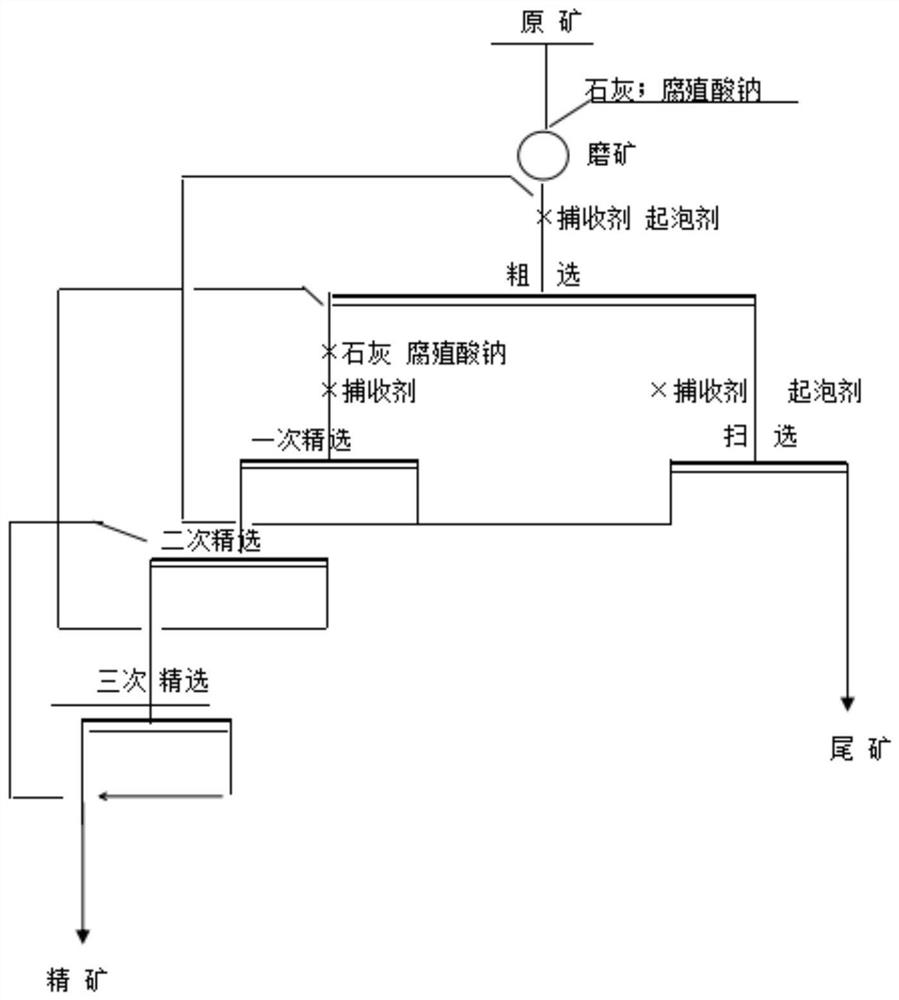

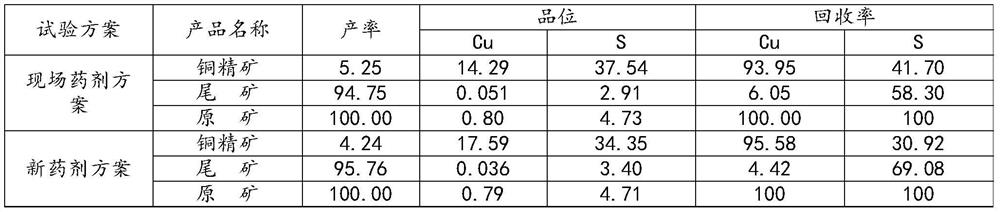

[0027] like figure 1 , the present embodiment provides a high-sulfur copper-zinc beneficiation method using sodium humate, comprising the following steps:

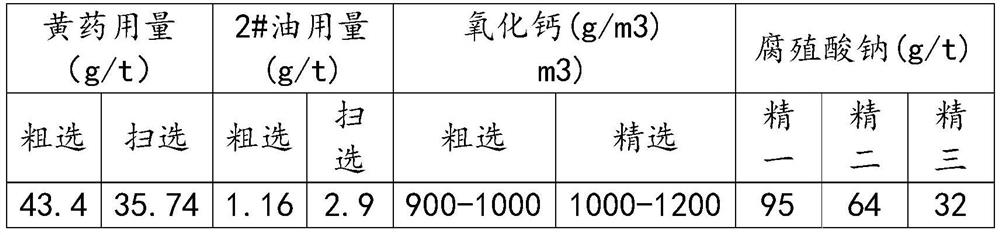

[0028] (1) Grinding, crushing and grinding the raw ore to fully dissociate copper sulfide minerals, zinc minerals and pyrite as monomers, adding a slurry pH adjuster and a pyrite inhibitor during grinding, and the slurry pH The adjusting agent is lime, the pyrite inhibitor is sodium humate, and the amount of lime added is 2000-3000g / t and the amount of sodium humate is 100-150g / t per ton of raw ore. When the weight concentration is 30-40%, the pH value of the pulp is controlled to be 9-9.5;

[0029] (2) Obtain the roughing concentrate and roughing tailings through one roughing, carry out a sweeping selection for the roughing tailings, carry out a selection, secondary selection, and three selections for the roughing concentrate, and sweep the intermediate ore Return to the selected medium ore sequentially to form a closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com