High-density ultra-fine grain molybdenum lanthanum alloy and preparation method thereof

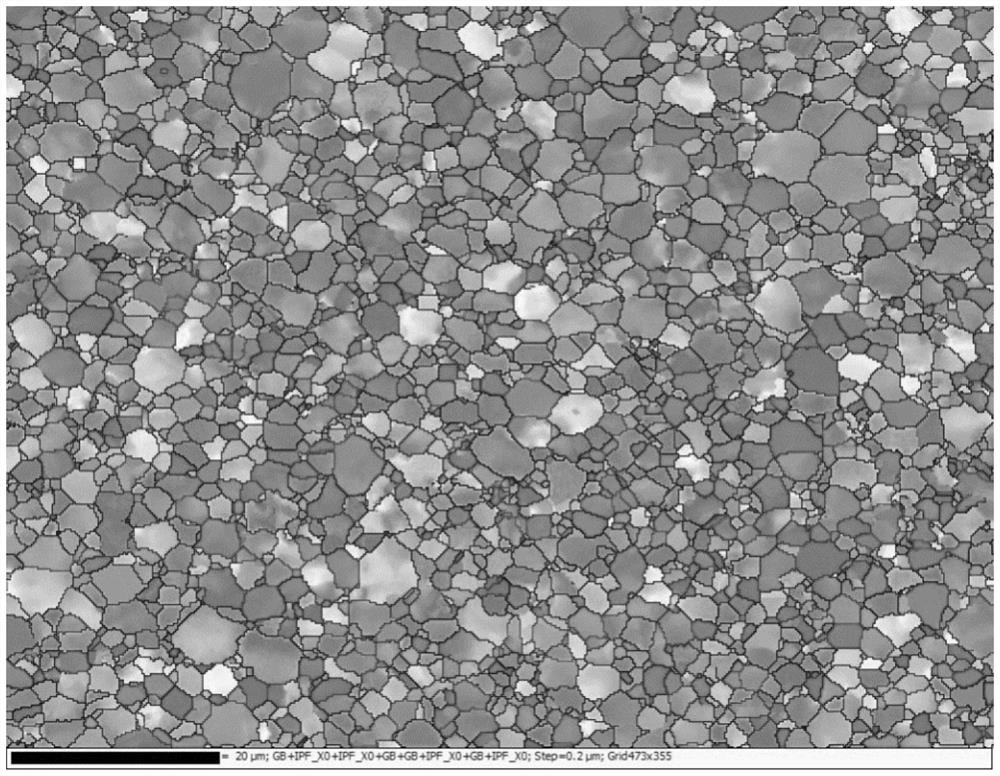

A molybdenum-lanthanum alloy and density technology is applied in the field of metallurgy, which can solve the problems of large grain size, poor performance and low density of molybdenum-lanthanum alloy, and achieve the effects of uniform composition and structure, reducing energy consumption and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The present embodiment provides a method for preparing a high-density ultrafine-grained molybdenum-lanthanum alloy, which specifically includes the following steps:

[0048] Step 1, preparing lanthanum oxide doped molybdenum dioxide powder;

[0049] Configuration of lanthanum oxide suspension: Weigh 1.188kg of rare earth lanthanum oxide powder into deionized water, fully stir it with a magnetic stirrer to completely disperse it, and obtain a lanthanum oxide suspension. Using high-pressure air, spray the prepared lanthanum oxide suspension into 150kg of molybdenum dioxide powder, and stir evenly while spraying to prepare mixture A. After heating and drying the prepared mixture A in a vacuum state, an oxidized Lanthanum doped molybdenum dioxide powder. The lanthanum oxide doped molybdenum dioxide powder is composed of the following raw materials in terms of mass percentage: 0.8% of lanthanum oxide and 99.2% of molybdenum dioxide.

[0050] Step 2, preparing molybdenum la...

Embodiment 2

[0060] This example presents a method for preparing a high-density ultrafine-grained molybdenum-lanthanum alloy, which is basically the same as Example 1, except that in step 5 of this example, after the third heat preservation is completed, the method is cooled to room temperature, and then a fourth temperature rise was performed to increase the temperature from room temperature to 1700 °C.

[0061] Using the preparation method of the high-density ultra-fine-grained molybdenum-lanthanum alloy in this embodiment, the final high-density ultra-fine-grained molybdenum-lanthanum alloy has a density of 99.2% and a grain size of about 3 μm.

Embodiment 3

[0063] This example presents a method for preparing a high-density ultrafine-grained molybdenum-lanthanum alloy, which is basically the same as Example 1, except that in step 5 of this example, after the third heat preservation is completed, the method is cooled to room temperature, and then a fourth temperature rise was performed to increase the temperature from room temperature to 1800 °C.

[0064] Using the preparation method of the high-density ultra-fine-grained molybdenum-lanthanum alloy in this embodiment, the final high-density ultra-fine-grained molybdenum-lanthanum alloy has a density of 99.4% and a grain size of about 3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com