Nuclear-grade polyacrylic acid as well as preparation method and application thereof

A technology of polyacrylic acid and acrylic acid monomer, which is applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. It can solve the problems of less impact on scale inhibition performance, achieve less environmental pollution, and produce Low cost and excellent anti-scaling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Weigh 200 g of n-butanol, 100 g of acrylic monomer, and 1 g of dicumyl peroxide, slowly add them to the reaction kettle, and mix them uniformly for 0.5 hours. Under the protection of high-purity argon, it was slowly heated to 75 °C and kept at a constant temperature for 6 hours. Then, 50 g of the resulting product was weighed and poured into 50 g of ethylene glycol methyl ether solvent, and the polyacrylic acid solid was precipitated. Next, the precipitated polyacrylic acid was dried at 70° C. for 4 hours, then taken out and smashed, followed by drying for 8 hours. Finally, the formed polyacrylic acid solid powder is the nuclear grade polyacrylic acid scale inhibitor.

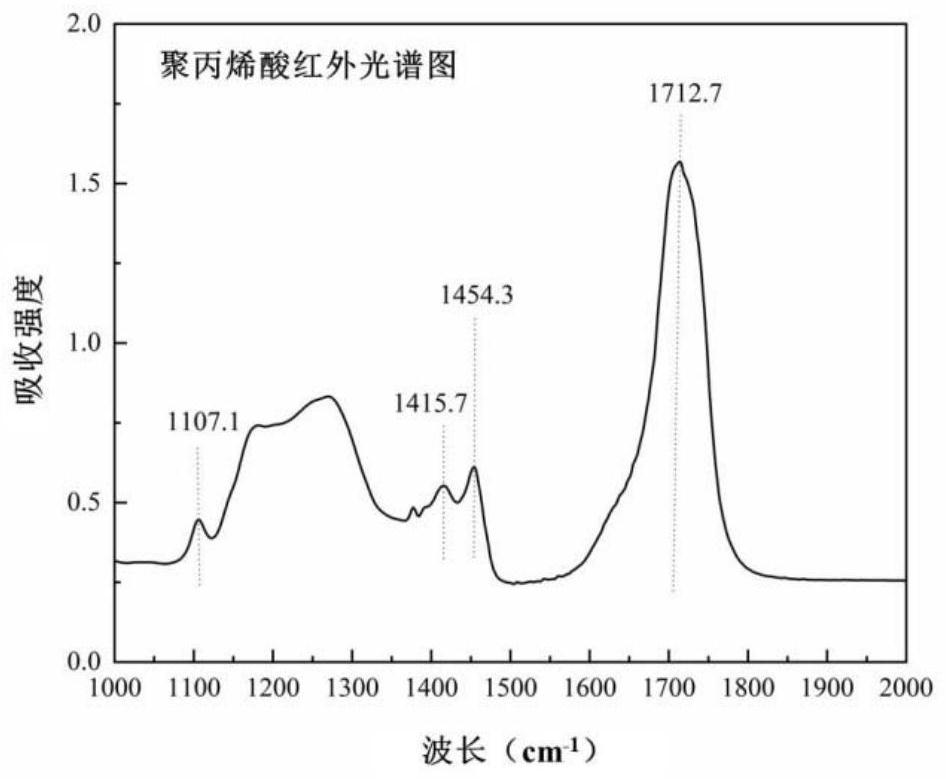

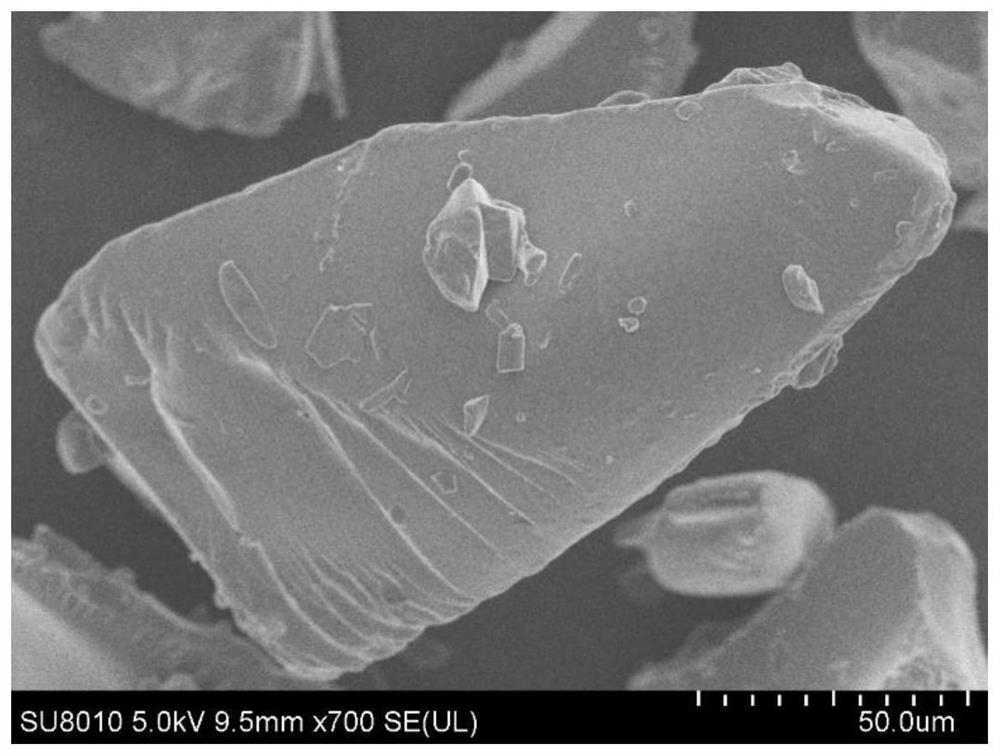

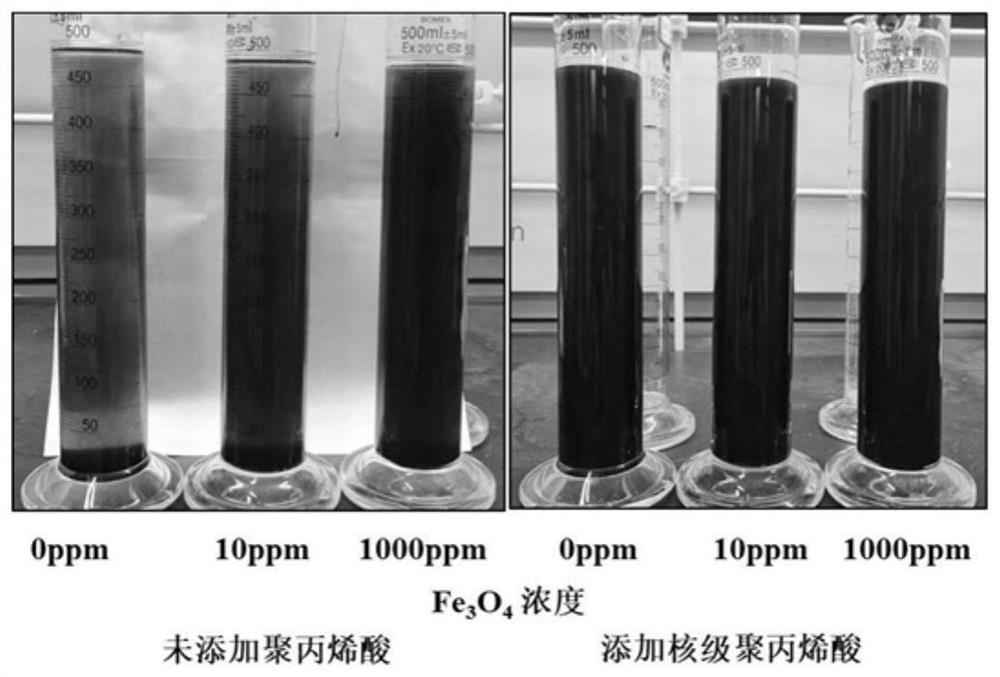

[0051] figure 1 It is the infrared spectrum of polyacrylic acid in Example 1, and the positions of the characteristic peaks in the spectrum correspond to the characteristic peaks of polyacrylic acid one by one, indicating that pure polyacrylic acid has been successfully prepared. figure 2 Optical mic...

Embodiment 2

[0053] Weigh 300 g of n-butanol, 100 g of acrylic monomer, and 1 g of azobisisobutyronitrile, and slowly add them to the reaction kettle and mix them uniformly for 1 hour. Under the protection of high-purity argon, it was slowly heated to 75 °C and kept at a constant temperature for 7 hours. Then, 50 g of the resulting product was weighed and poured into 100 g of ethylene glycol methyl ether solvent, and the polyacrylic acid solid was precipitated. Next, the precipitated polyacrylic acid was dried at 75° C. for 5 hours, then taken out and smashed, followed by drying for 7 hours. Finally, the formed polyacrylic acid solid powder is the nuclear grade polyacrylic acid scale inhibitor.

Embodiment 3

[0055] Weigh 400 g of n-butanol, 100 g of acrylic monomer, and 1 g of hydrogen peroxide, slowly add them into the reaction kettle, and mix them uniformly for 1.5 hours. Under the protection of high-purity argon, it was slowly heated to 80 °C and kept at a constant temperature for 8 hours. Then, 50 g of the resulting product was weighed and poured into 150 g of ethylene glycol methyl ether solvent, and the polyacrylic acid solid was precipitated. Next, the precipitated polyacrylic acid was dried at 80° C. for 6 hours, then taken out and smashed, followed by drying for 6 hours. Finally, the formed polyacrylic acid solid powder is the nuclear grade polyacrylic acid scale inhibitor.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap