High-mechanical-strength self-repairing self-adhesive polysiloxane elastomer and preparation method thereof

A technology of polysiloxane and mechanical strength, applied in the field of high mechanical strength self-healing and self-adhesive polysiloxane elastomer and its preparation, can solve the problems of unreported, poor mechanical properties, limited application fields, etc. problems, to achieve the effect of easy-to-obtain raw materials, low cost, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

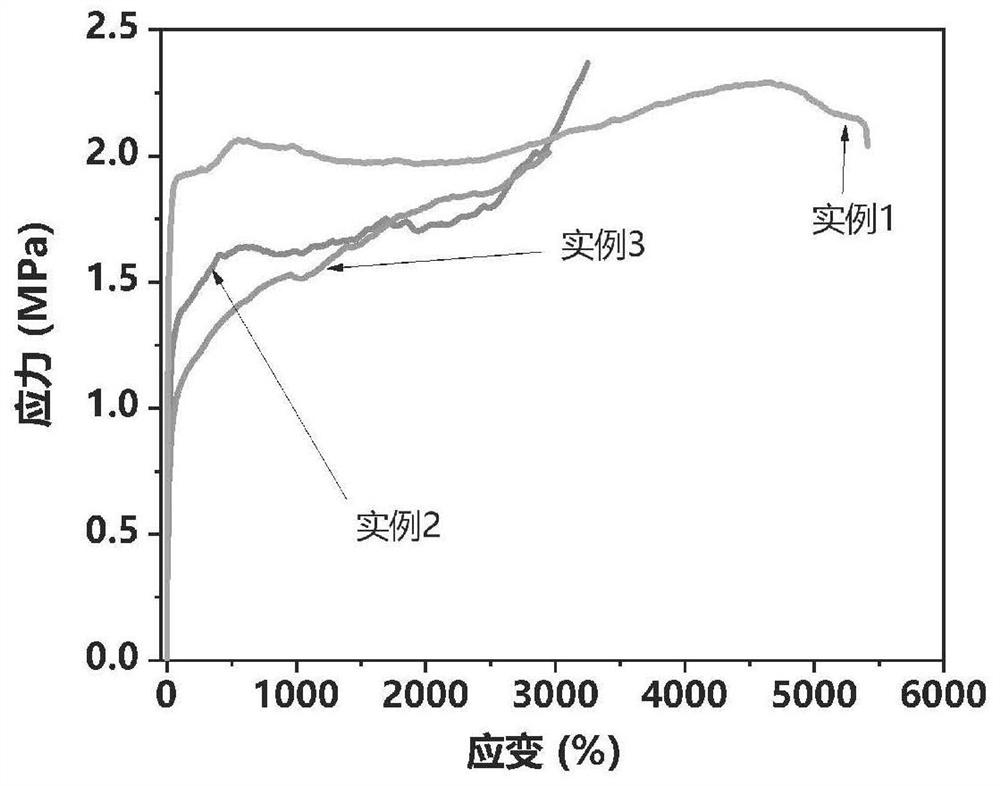

Embodiment 1

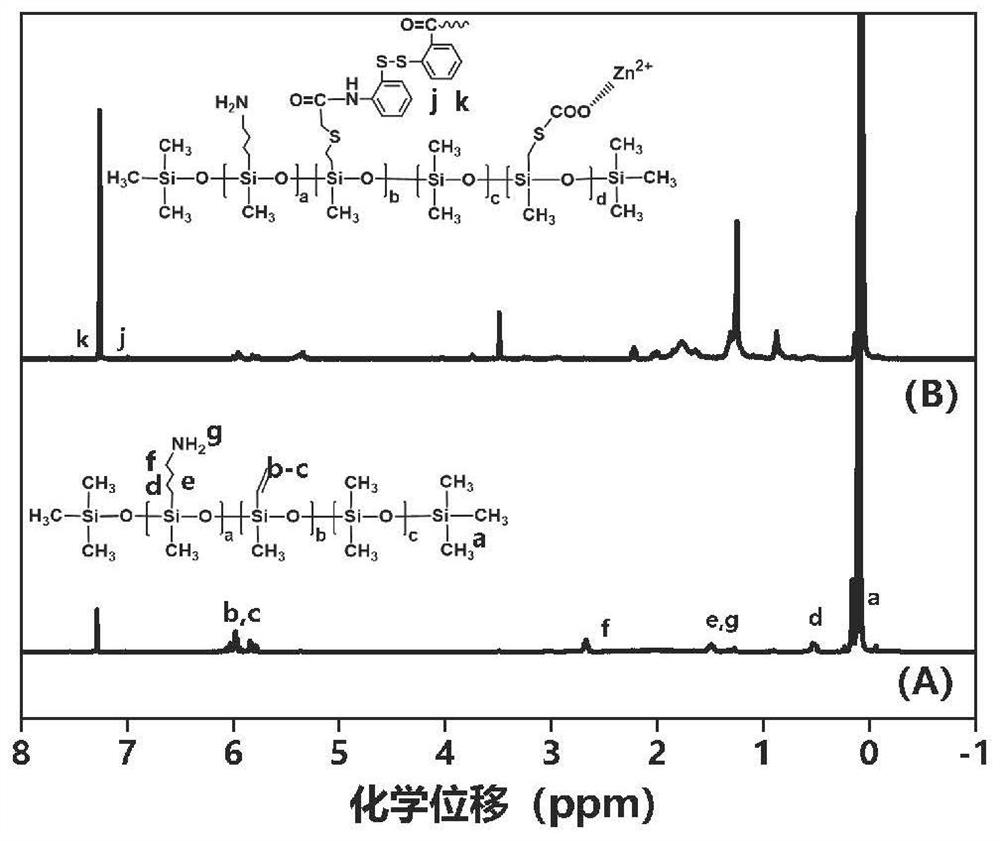

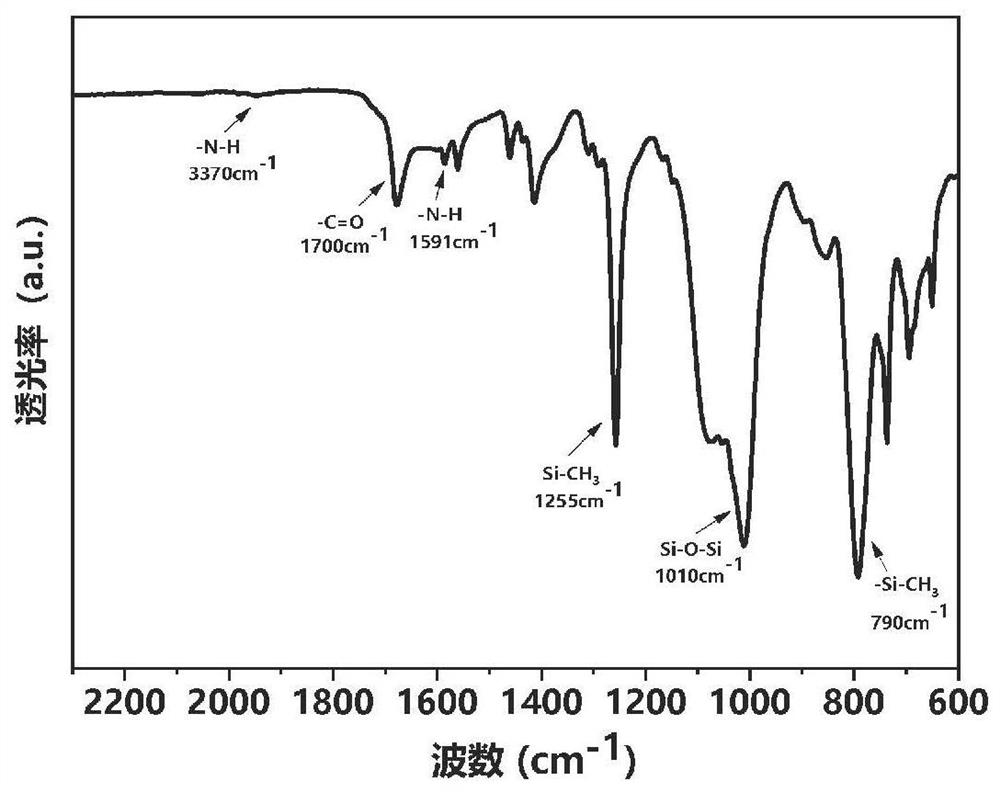

[0059] 1) Take 10g of side methylaminopropyl vinyl polysiloxane (Mn=50000g mol -1 , the molar ratio of methyl, aminopropyl and vinyl in the side methylaminopropyl vinyl polysiloxane is 8:1:1, that is, c:a:b=8:1:1), which is fully dissolved in After adding 0.2g of 2,2-dimethylolpropionic acid and 1.152g of mercaptoacetic acid to 20ml of tetrahydrofuran, stir until uniform, and then place it under a UV lamp to stir and irradiate for 15min to take out;

[0060] 2) Add 3.5 g of dithiodibenzoic acid to the prepared polymer, mix it evenly, place it at 60°C for stirring and react for 3 hours, and take it out;

[0061] 3) Finally, add 6.22ml of 0.1g / ml anhydrous zinc chloride solution to the polymer, stir evenly for 12h and wait for it to fully react, then pour it into the mold and place it in a fume hood to level at room temperature, and move it to 90°C after the tetrahydrofuran is volatilized. After drying in a vacuum oven for 12 hours, the mold is released to obtain a high-mechani...

Embodiment 2

[0063] 1) Take 10g of side methylaminopropyl vinyl polysiloxane (Mn=30000g mol -1 , the molar ratio of methyl, aminopropyl and vinyl in the side methylaminopropyl vinyl polysiloxane is 14:3:3, that is, c:a:b=14:3:3), which is fully dissolved in After adding 0.3g of 2,2-dimethylolpropionic acid and 0.23g of mercaptoacetic acid to 20ml of tetrahydrofuran, stir until uniform, and then place it under a UV lamp to stir and irradiate for 30min to take out;

[0064] 2) Add 1.76 g of dithiodibenzoic acid to the prepared polymer, mix it evenly, place it at 60° C. for stirring and react for 3 hours, and take it out;

[0065] 3) Finally, add 8.34ml of 0.1g / ml anhydrous ferric chloride solution to the polymer, stir evenly for 10h and wait for it to fully react, then pour it into the mold and place it in a fume hood to level at room temperature. After the tetrahydrofuran is volatilized, move it to 120°C After drying in a vacuum oven for 12 hours, the mold was released to obtain an elastom...

Embodiment 3

[0067] 1) Take 10g of side methylaminopropyl vinyl polysiloxane (Mn=35000g mol -1 , the molar ratio of methyl, aminopropyl and vinyl in the side methylaminopropyl vinyl polysiloxane is 6:2:2, that is, c:a:b=6:2:2), which is fully dissolved in After adding 0.2g of 2,4,6-trimethylbenzoyl-diphenylphosphorus oxide and 0.46g of mercaptoacetic acid to 20ml of tetrahydrofuran, stir until uniform, and then place it under a UV lamp to stir and irradiate for 20min to take out;

[0068] 2) Add 2.3 g of dithiodibenzoic acid to the prepared polymer, mix it evenly, place it at 65°C and stir for 3 hours and take it out;

[0069] 3) Finally, add 3.11 ml of 0.2 g / ml anhydrous zinc chloride solution to the polymer, stir evenly for 12 hours and wait for it to fully react, then pour it into the mold and place it in a fume hood to level at room temperature, and move it to 100 ° C after the tetrahydrofuran is volatilized After drying in a vacuum oven for 10 hours, the mold was released to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com