Mercaptan epoxy elastomer material and preparation method and application thereof

An elastomer material, epoxy technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of difficult recycling or repair, difficult to prepare high thermal conductivity self-healing system, unable to reshape, etc. Self-healing performance, simple and easy preparation process, good recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

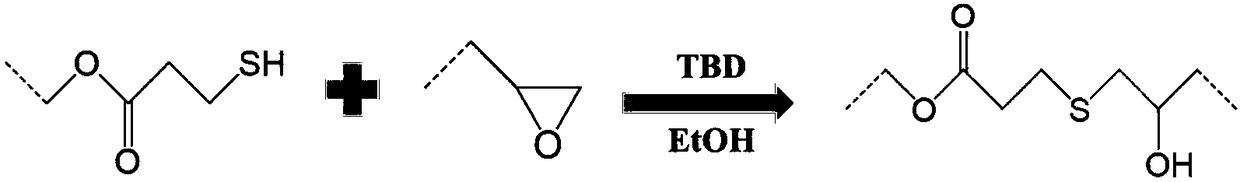

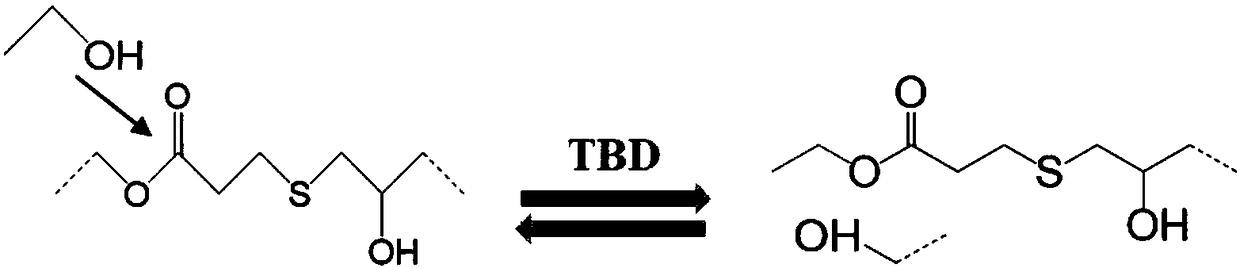

[0033] The invention provides a kind of preparation method of mercaptan epoxy elastomer material, comprises the following steps:

[0034] Mix monomer I, monomer II, 1,5,7-triazabicyclo[4,4,0]dec-5-ene with an organic solvent, and undergo a thiol-epoxy nucleophilic ring-opening reaction to obtain Thiol epoxy elastomer material;

[0035] Wherein, the monomer I is:

[0036]

[0037] The monomer II is:

[0038]

[0039] In the present invention, unless otherwise specified, all raw materials are commercially available products or sources known to those skilled in the art.

[0040] In the present invention, the molar ratio of the mercapto groups in the monomer I to the epoxy groups in the monomer II is preferably 1:(0.9-1.1), more preferably 1:1.

[0041] In the present invention, the mass ratio of the monomer II to 1,5,7 triazabicyclo[4,4,0]dec-5-ene is preferably (40-50):1, more preferably ( 42-48):1, most preferably (44-46):1. In the present invention, the 1,5,7 triaza...

Embodiment 1

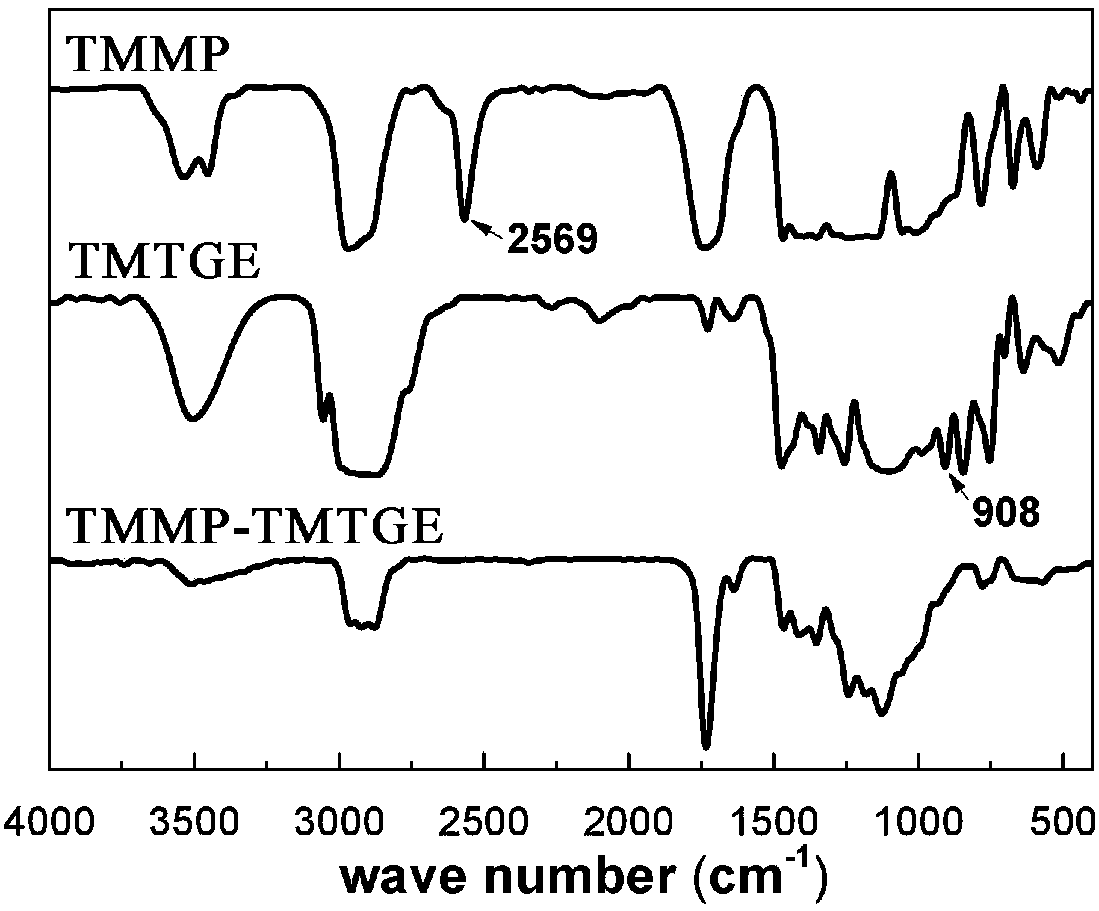

[0063] At 22°C, 2.0g (6.62mmol) trimethylolpropane triglycidyl ether (TMTGE), 2.65g (6.62mmol) trimethylolpropane tris (3-mercaptopropionate) (TMMP) and 46mg 1,5,7-Triazabicyclo[4,4,0]dec-5-ene (TBD) was mixed evenly, then 0.5mL absolute ethanol was added at a rate of 1ml / min, and the thiol- Epoxy nucleophilic ring-opening reaction to obtain thiol epoxy elastomer material;

[0064] The thiol epoxy elastomer material was hot-pressed at 180° C. and 10 MPa for 1 hour to obtain a thermally conductive self-healing material.

[0065] The thermal conductivity (λ) of the self-healing material is 0.2693W / mK (see Figure 4 ), glass transition temperature (T g ) is -23.50℃ (see Figure 6 ); Described self-healing material is measured its tensile strength according to ASTM D412 standard, and test result is 0.77MPa (see Figure 5 );

[0066] The self-healing material is subjected to tensile failure according to ASTM D412 conditions, and the self-healing material after tensile failure ...

Embodiment 2

[0068] At 25°C, 2.0g (6.62mmol) trimethylolpropane triglycidyl ether (TMPGE), 2.65g (6.62mmol) trimethylolpropane tris (3-mercaptopropionate) (TMPMP), 43mg 1,5,7-Triazabicyclo[4,4,0]dec-5-ene (TBD) and 0.235g micron boron nitride (mBN) were mixed evenly, and then added to 1mL at a rate of 1.5ml / min Absolute ethanol, 0.8min to complete the thiol-epoxy nucleophilic ring-opening reaction to obtain a thiol-epoxy elastomer material;

[0069] The thiol epoxy elastomer material was hot-pressed at 180°C and 8MPa for 1 hour to obtain a self-healing material;

[0070] The thermal conductivity (λ) of the self-healing material is 0.3485W / mK (see Figure 4 ), the glass transition temperature (Tg) is -20.33°C (see Figure 6 ); Described self-healing material is measured its tensile strength according to ASTM D412 standard, and test result is 1.88MPa (see Figure 5 );

[0071] The self-healing material is subjected to tensile failure according to ASTM D412 conditions, and the self-healin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com