Self-repairing polythiourethane protective coating material preparation method and product thereof

A polythiourethane and protective coating technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as material failure, and achieve the effects of reinforced materials, simple synthesis methods, and high reaction yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

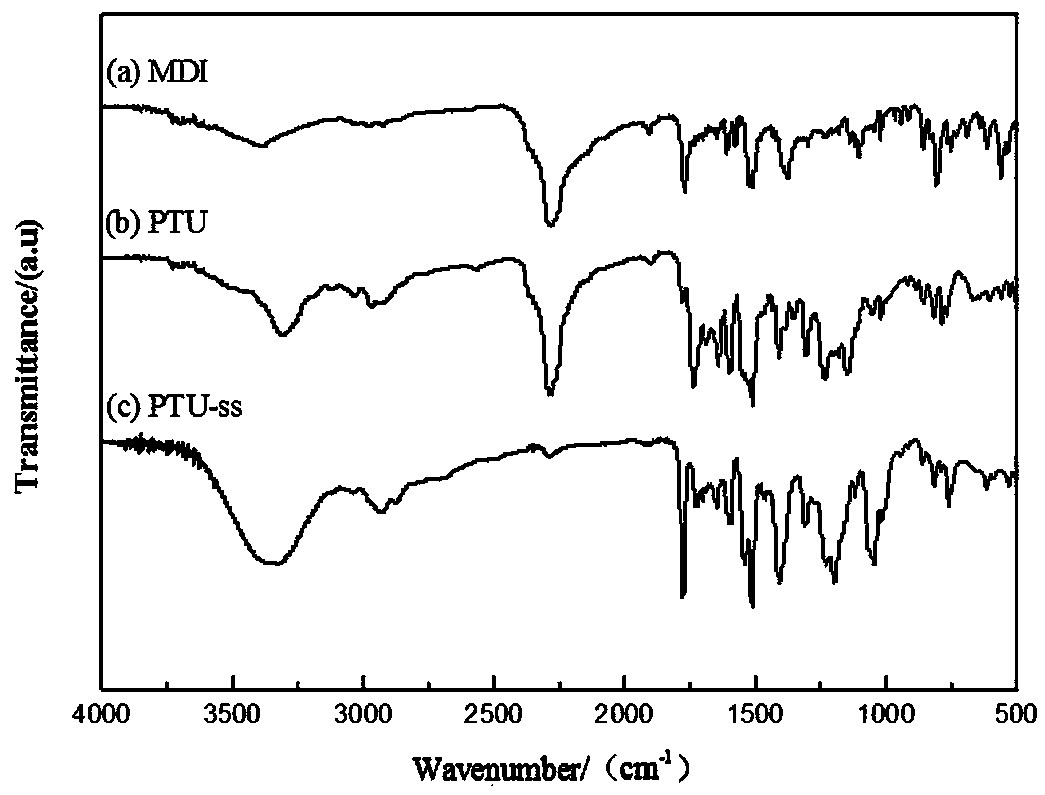

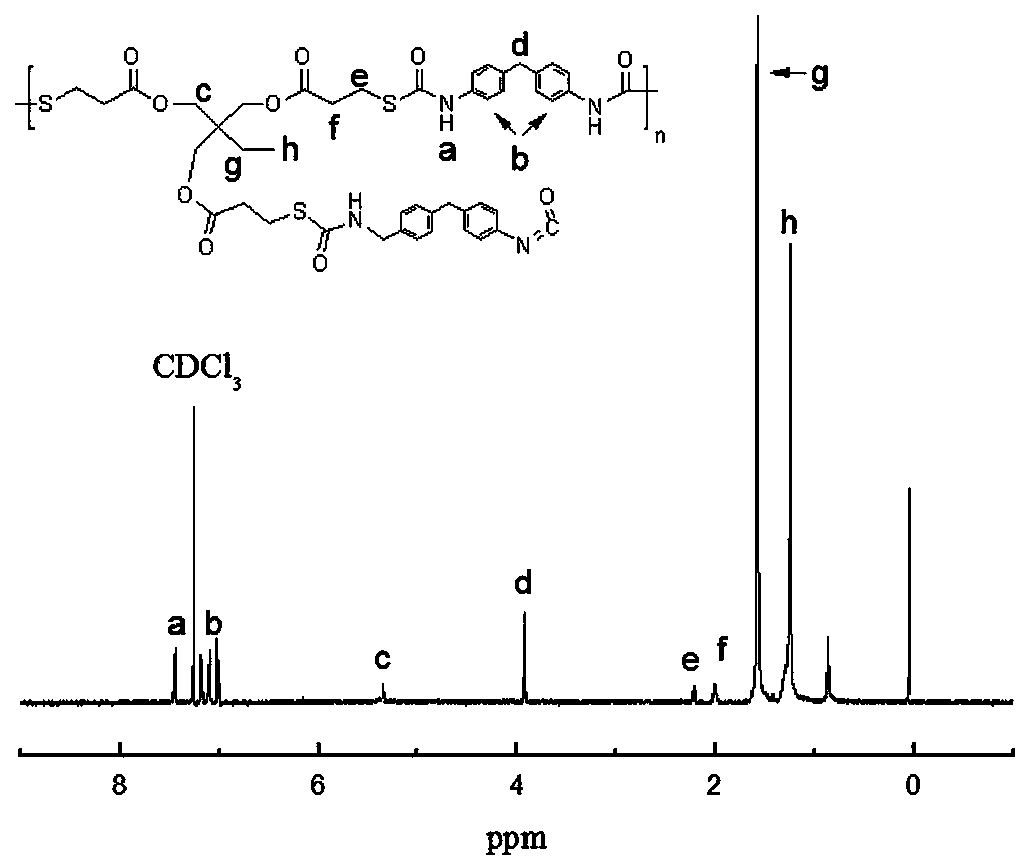

[0021] A self-healing polythiourethane material is prepared from a small molecular compound containing a disulfide bond and an isocyanate-terminated polythiourethane, and the specific steps are as follows;

[0022] (1) Calculate and weigh raw materials.

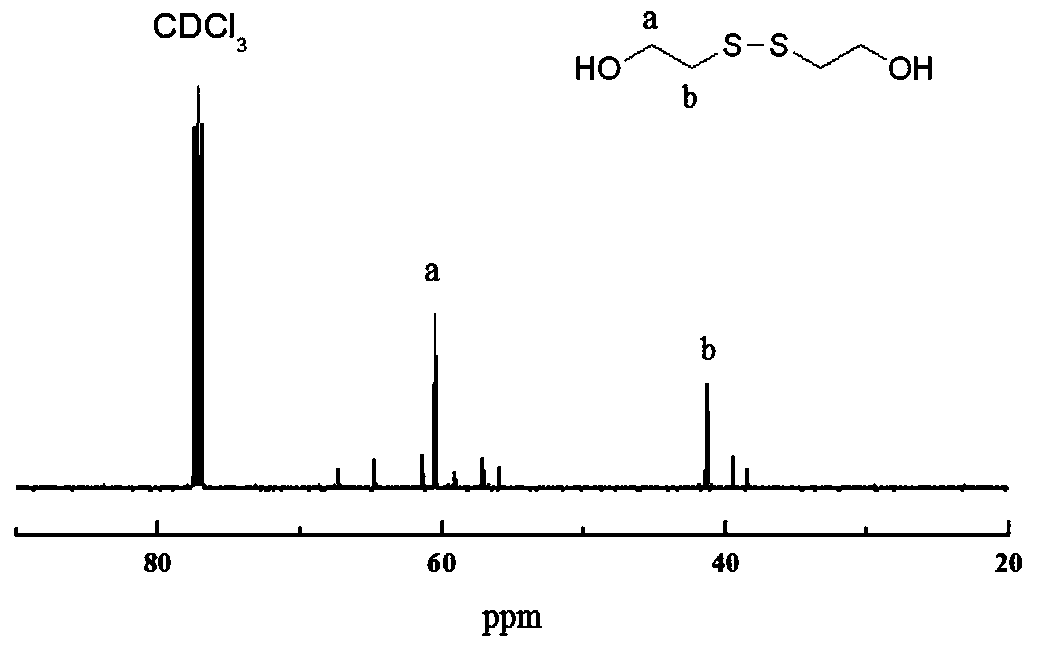

[0023] (2) Preparation of small molecule compounds containing disulfide bonds: Weigh 0.9 mL of β-mercaptoethanol into a 150 mL beaker, stir well, then quickly add 1.1 mL of triethylamine (TEA) dropwise, and keep the reaction vessel open to air contact, slowly and dropwise add 1.3 mL of H 2 o 2 (30%), white turbidity will be produced during the dropping process, and a large amount of heat will be released. When the temperature of the beaker is cooled to room temperature, continue to add H 2 o 2 (30%), after the dropwise addition, continue to stir until the solution is colorless and transparent, remove the reaction solvent and dry in vacuum at 60 °C overnight to constant weight.

[0024] (3) Preparation of isocyanate-termin...

Embodiment 2

[0027] A preparation of a self-healing polythiourethane material, which is prepared from a small molecular compound containing a disulfide bond and an isocyanate group-terminated polythiourethane, and the specific steps are as follows;

[0028] (1) Calculate and weigh raw materials.

[0029] (2) Preparation of small molecule compounds containing disulfide bonds: Weigh 2.7 mL of β-mercaptoethanol solution in a 150 mL beaker, stir well, then quickly add 3.3 mL of triethylamine (TEA) solution dropwise, and keep the reaction vessel open In contact with air, slowly and dropwise add 3.9 mL of H 2 o 2 (30%) solution, white turbidity will be generated during the dropping process, and a large amount of heat will be released. When the temperature of the beaker is cooled to room temperature, continue to add H 2 o 2 (30%), after the dropwise addition, continue to stir until the solution is colorless and transparent, remove the reaction solvent and dry in vacuum at 60 °C overnight to co...

Embodiment 3

[0033] A preparation of a self-healing polythiourethane material, which is prepared from a small molecular compound containing a disulfide bond and an isocyanate group-terminated polythiourethane, and the specific steps are as follows;

[0034](1) Calculate and weigh raw materials.

[0035] (2) Preparation of small molecular compounds containing disulfide bonds: Weigh 2.7 mL of β-mercaptoethanol into a 150 mL beaker, stir well, then quickly add 3.3 mL of triethylamine (TEA) dropwise, and keep the reaction vessel open to the air. contact, slowly and dropwise add 5.2 mL of H 2 o 2 (30%), white turbidity will be produced during the dropping process, and a large amount of heat will be released. When the temperature of the beaker is cooled to room temperature, continue to add H 2 o 2 (30%), after the dropwise addition, continue to stir until the solution is colorless and transparent, remove the reaction solvent and dry in vacuum at 60 °C overnight to constant weight.

[0036] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com