Antioxidant self-repairing lubricating oil containing graphene oxide

A self-healing and graphene technology, applied in the field of lubricating oil, can solve the problems of poor anti-freezing and anti-oxidation performance, no self-repairing effect, etc., and achieve the effect of improving self-repairing performance, improving anti-oxidation performance and good anti-oxidizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

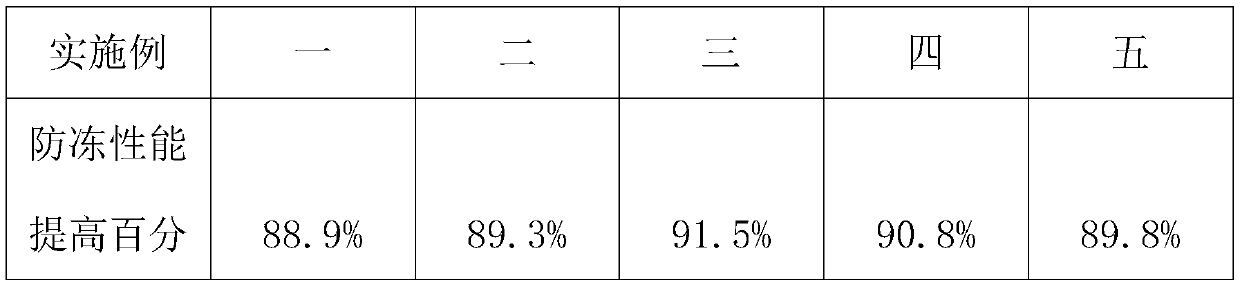

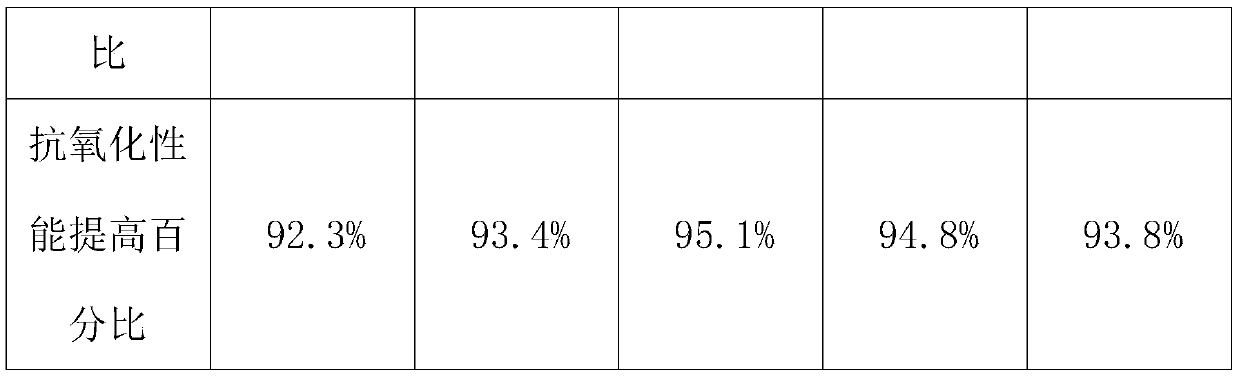

Examples

Embodiment 1

[0034] The present invention proposes an anti-oxidant self-repair lubricating oil containing graphene oxide, which includes the following raw materials in parts by weight: 30 parts of tetratitanic acid, 40 parts of graphene oxide, 50 parts of lubricating base oil, p-hydroxybenzyl 10 parts of aldehyde, 3 parts of sodium polyacrylate, 2 parts of sulfurized calcium alkylphenate, 1 part of polyvinyl alcohol, 4 parts of sodium sulfate, 7 parts of polycarboxylate superplasticizer, 8 parts of sodium lignosulfonate, 15 parts of nitrite 20 parts of zinc dialkyl dithiophosphate, 1 part of polybutenyl succinic acid amide, 10 parts of polymethacrylate, 5 parts of calcium chloride, 1 part of sodium acetate, 10 parts of magnesium chloride, acid phosphate amine 20 parts of salt, 5 parts of alkylamine, 6 parts of propylene glycol, 4 parts of triethanolamine, 3 parts of thiodipropionic acid, 2 parts of tert-butyl hydroquinone, 5 parts of dimer acid ethylene glycol monoester;

[0035] Its prepa...

Embodiment 2

[0041] The present invention proposes an anti-oxidant self-repair lubricating oil containing graphene oxide, which includes the following raw materials in parts by weight: 32 parts of tetratitanic acid, 42 parts of graphene oxide, 52 parts of lubricating oil base oil, p-hydroxybenzyl 11 parts of aldehydes, 4 parts of sodium polyacrylate, 3 parts of sulfurized calcium alkylphenate, 2 parts of polyvinyl alcohol, 5 parts of sodium sulfate, 8 parts of polycarboxylate superplasticizer, 9 parts of sodium lignosulfonate, 16 parts of nitrite Parts, 21 parts of zinc dialkyl dithiophosphate, 2 parts of polybutenyl succinic acid amide, 11 parts of polymethacrylate, 6 parts of calcium chloride, 2 parts of sodium acetate, 11 parts of magnesium chloride, acidic phosphate amine 21 parts of salt, 6 parts of alkylamine, 7 parts of propylene glycol, 5 parts of triethanolamine, 4 parts of thiodipropionic acid, 3 parts of tert-butyl hydroquinone, 7 parts of dimer acid ethylene glycol monoester;

...

Embodiment 3

[0048] The present invention proposes an anti-oxidant self-repairing lubricating oil containing graphene oxide, which includes the following raw materials in parts by weight: 34 parts of tetratitanic acid, 44 parts of graphene oxide, 54 parts of lubricating base oil, p-hydroxybenzyl 12 parts of aldehyde, 5 parts of sodium polyacrylate, 4 parts of sulfurized calcium alkylphenate, 3 parts of polyvinyl alcohol, 6 parts of sodium sulfate, 9 parts of polycarboxylate superplasticizer, 10 parts of sodium lignosulfonate, 17 parts of nitrite 22 parts, zinc dialkyldithiophosphate 22 parts, polybutenyl succinic acid amide 3 parts, polymethacrylate 12 parts, calcium chloride 7 parts, sodium acetate 3 parts, magnesium chloride 12 parts, acid phosphate amine 22 parts of salt, 7 parts of alkylamine, 8 parts of propylene glycol, 6 parts of triethanolamine, 5 parts of thiodipropionic acid, 4 parts of tert-butyl hydroquinone, 7 parts of dimer acid ethylene glycol monoester;

[0049] Its prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com