Flame-retardant flexible polyvinyl chloride plastic and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, applied in the field of plastics, which can solve the problems of poor mechanical properties of polyvinyl chloride plastics, toxicity of organic flame retardants, and large application limitations, so as to improve the blending effect and stability properties, reduce the effect of mechanical strength decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

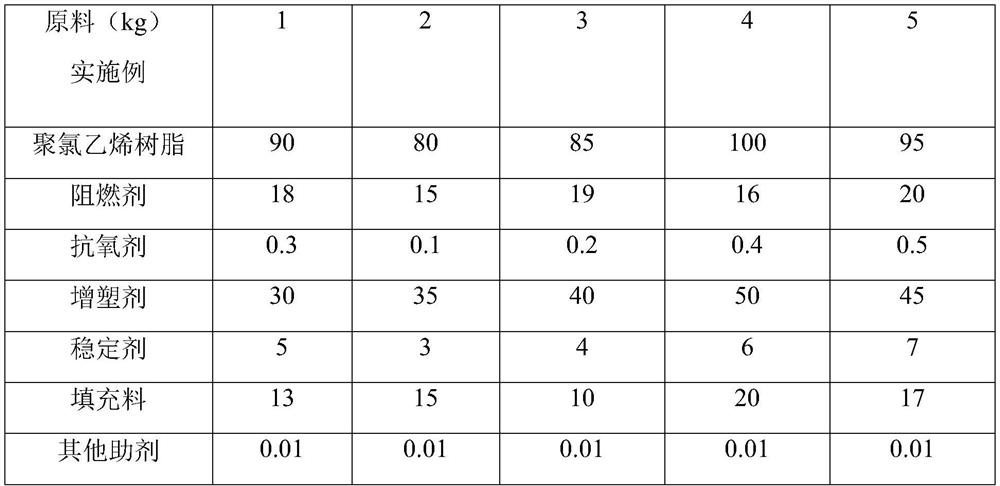

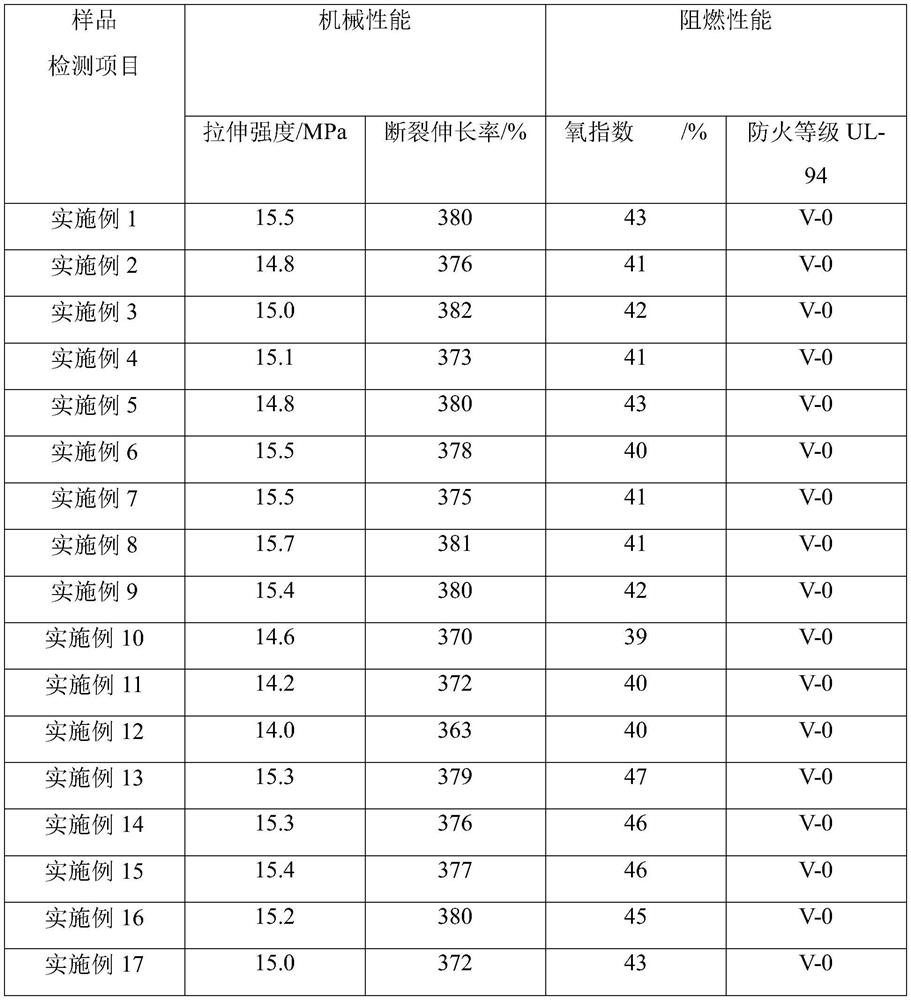

Examples

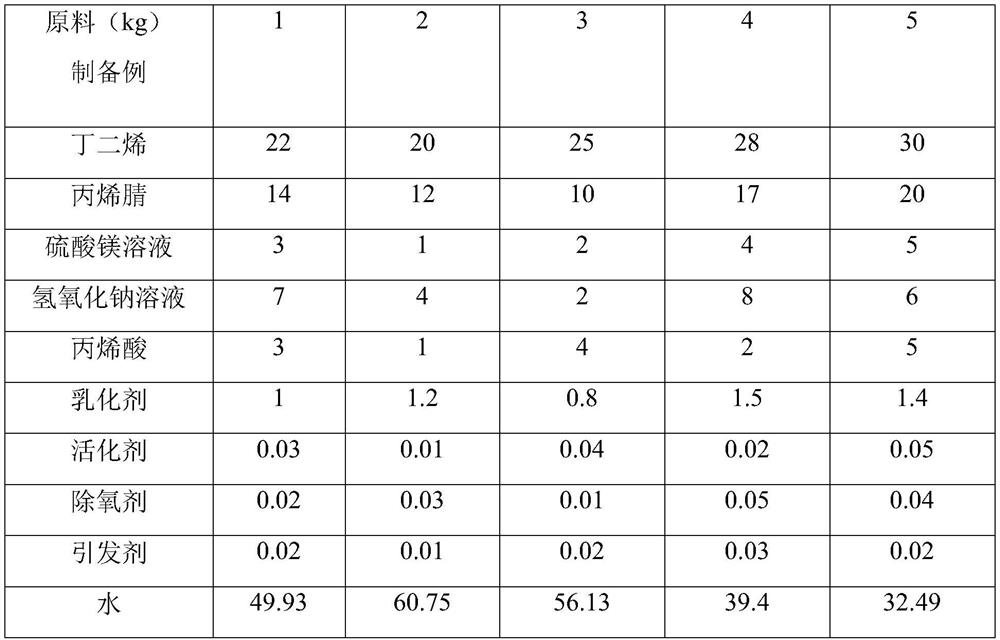

preparation example 1

[0042] A flame retardant, comprising a mixture formed by grafting nitrile rubber with magnesium hydroxide; and the mixture formed by grafting nitrile rubber with magnesium hydroxide comprises the following raw materials:

[0043] Butadiene 22kg, acrylonitrile 14kg, magnesium sulfate solution 3kg, sodium hydroxide solution 7kg, acrylic acid 3kg, emulsifier 1kg, activator 0.03kg, oxygen scavenger 0.02kg, initiator 0.02kg, water 49.93kg;

[0044] Wherein the mass concentration of magnesium sulfate solution is 10%, and the mass concentration of sodium hydroxide is 10%;

[0045] The emulsifier is fatty acid soap;

[0046] The activator is ethylenediaminetetraacetic acid;

[0047] The initiator is dicumyl hydrogen peroxide.

[0048] The preparation method of the flame retardant comprises the following steps:

[0049] (1) mixing magnesium sulfate solution and sodium hydroxide solution at a temperature of 40 ℃, and obtaining magnesium hydroxide prefabricated solution after reaction...

preparation example 6

[0056] The difference between this preparation example and preparation example 1 is that the mass concentration of the magnesium sulfate solution is 15%.

preparation example 7

[0058] The difference between this preparation example and preparation example 1 is that the mass concentration of sodium hydroxide is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap