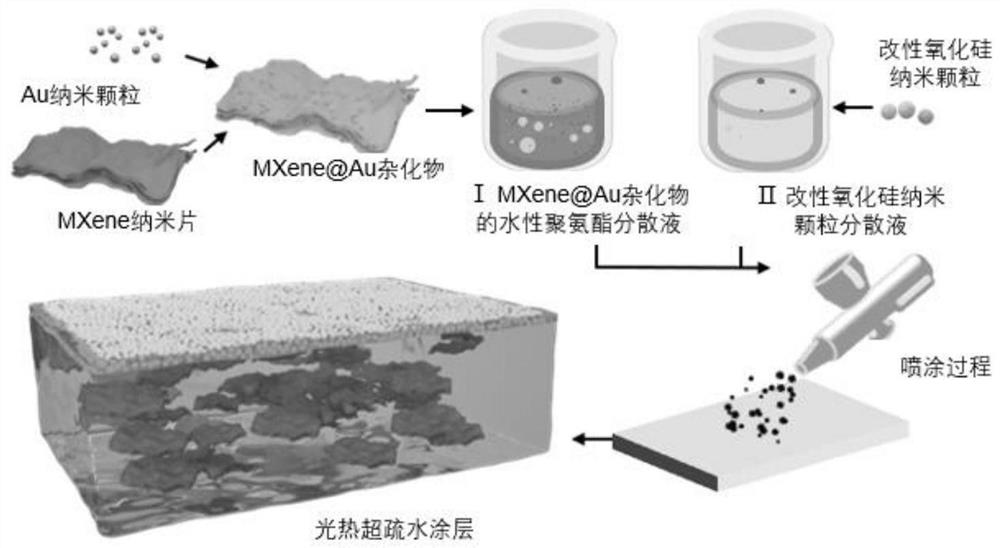

Photo-thermal super-hydrophobic coating based on MXene (at) Au hybrid and preparation method of photo-thermal super-hydrophobic coating

A technology of super-hydrophobic coatings and hybrids, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problem of low photothermal conversion efficiency of photothermal superhydrophobic coatings, and achieve improved photothermal conversion efficiency and excellent stability The effect of superhydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of photothermal superhydrophobic coating based on MXene@Au hybrid, comprising the following steps:

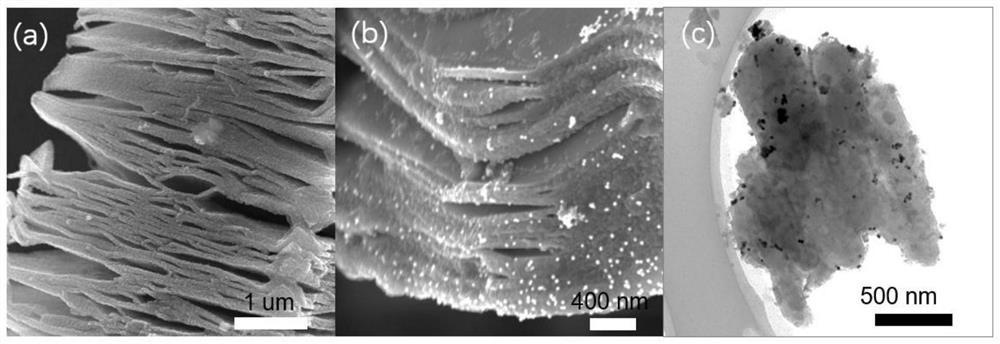

[0045] (1) Preparation of MXene nanosheets

[0046] Slowly add 10 mL of concentrated hydrochloric acid (6 mol / L) to 10 mL of deionized water, and stir well. Add 1 g of lithium fluoride powder to the solution and stir for 20 min to dissolve. Slowly add 1 g of MAX powder to the solution in several times, and after stirring for 30 minutes, turn on the heating, and make the mixed solution stir and react at a temperature of 55° C. and a rotation speed of 400 rpm for 24 hours. After the reaction was completed, the reaction was washed with water by ultrasonic centrifugation several times until the pH value was close to 7. The centrifuged product was placed in a vacuum drying oven and dried at 40 °C overnight to obtain MXene nanosheets.

[0047] (2) Preparation of gold nanoparticle dispersion

[0048] Prepare 10 mL of 0.1 mol / L cetyltrimethylammonium bro...

Embodiment 2

[0064] The photothermal superhydrophobic coating containing only MXene was prepared according to the same steps in Example 1 (the MXene powder was 1%, 2% and 4% according to the mass fraction of the aqueous polyurethane dispersion, without Au doping). like Figure 12As shown, for the photothermal superhydrophobic coatings containing different mass fractions of MXene prepared separately, when the mass fraction of MXene powder accounted for 3% of the aqueous polyurethane dispersion, the absorption spectrum of the coating showed the best performance, so based on this For optimization, the mass fraction of MXene powder in the aqueous polyurethane dispersion is set to be 3%. Therefore, when the mass fraction of MXene nanosheets in the aqueous polyurethane dispersion is less than 3%, the light absorption rate of the prepared coating increases with the mass fraction of MXene; and when the mass fraction of MXene nanosheets in the aqueous polyurethane dispersion exceeds At 3%, the lig...

Embodiment 3

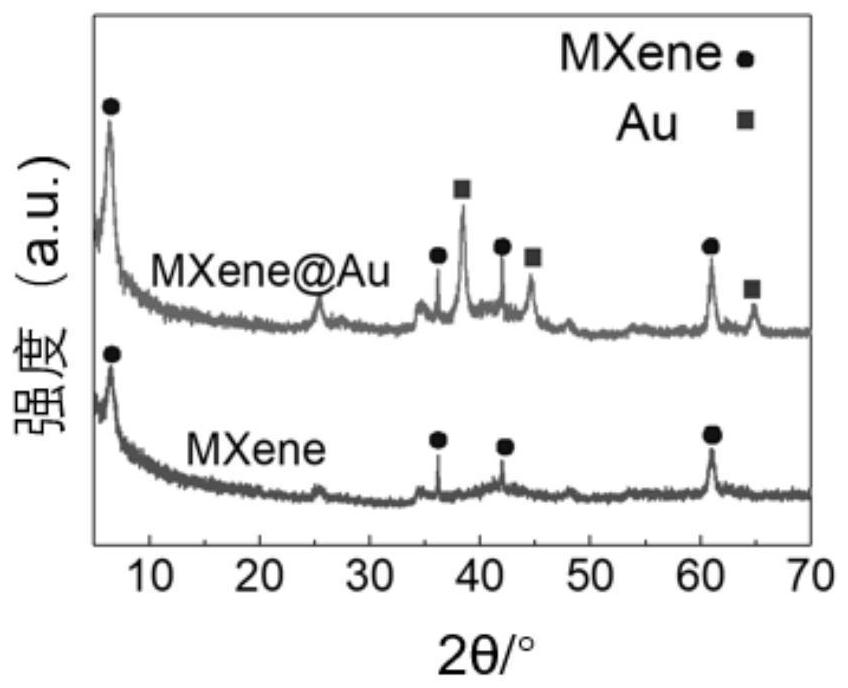

[0066] The photothermal superhydrophobic coating containing MXene@Au was prepared according to the same steps as in Example 1, except that in the step (3), the mass ratio of MXene to Au was 12:1, 10:1 and 6 The corresponding photothermal superhydrophobic coatings were prepared separately from 1. like Figure 13 As shown, for Example 1 and Example 3, the coatings containing different mass ratios of MXene to Au were prepared, when the mass ratio of MXene to Au was 8 to 1, the absorbance spectra of the coatings showed the best performance , so based on this optimization, the mass ratio of MXene to Au is set to 8:1. When the mass ratio of MXene to Au in the MXene@Au hybrid dispersion is too high and the content of Au particles is low, the plasmon effect and photothermal synergistic effect are not obvious, and the coating absorption rate is not high. The light-to-heat conversion performance is not high. When the mass ratio of MXene to Au in the MXene@Au hybrid is too low, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com