Integrated vertical two-phase anaerobic reaction device and process

An anaerobic reaction device and vertical technology, applied in the field of anaerobic reactors, can solve the problems of low methane production efficiency and low system integration efficiency, and achieve reduction of reactor volume, improvement of reaction mass transfer efficiency, separation The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

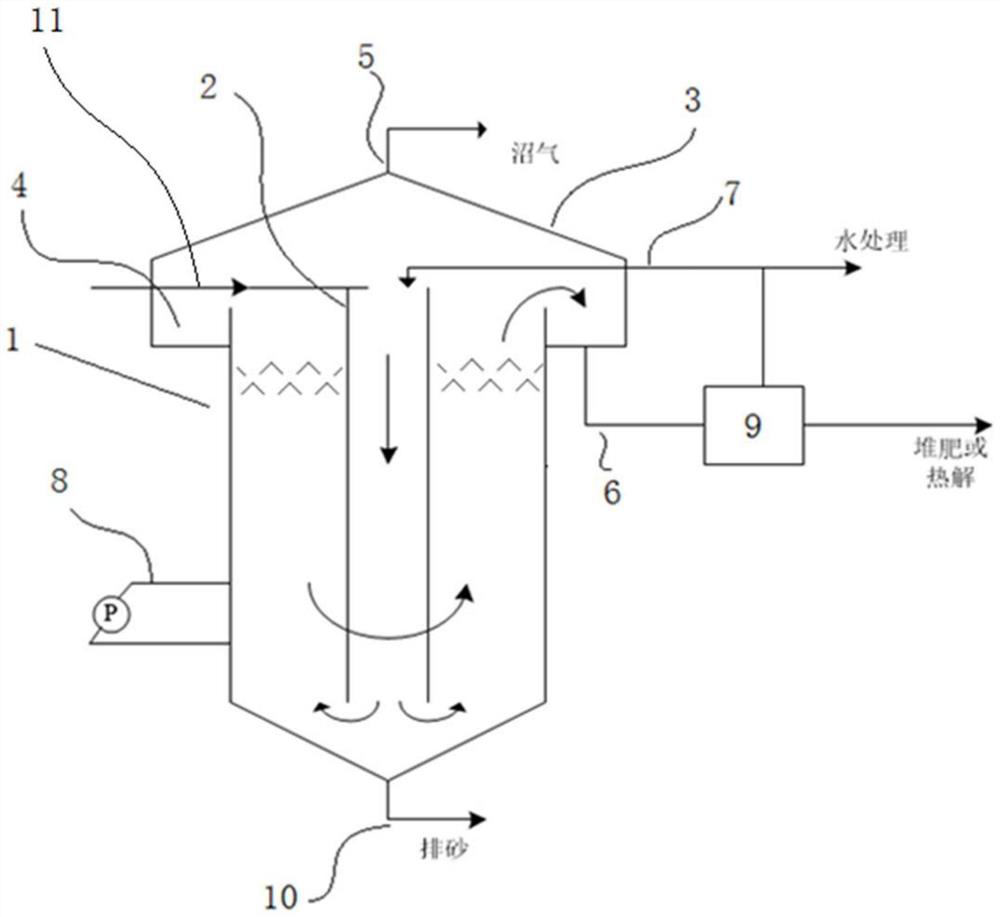

[0048] This embodiment provides an integrated vertical two-phase anaerobic reaction device, the structure of which is shown in figure 1 As shown, the reaction tank 1 is included, and a central inner cylinder 2 is arranged in the middle position of the reaction tank 1, so that a hydrolysis and acidification reaction zone located in the central inner cylinder 2 is formed in the reaction tank 1, and the inner wall of the reaction tank 1 is formed. With the methane-producing zone between the outer walls of the central inner cylinder 2, the hydrolysis and acidification reaction zone is communicated with the bottom of the methane-producing zone, and the top of the reaction tank body 1 is also sealed with a reaction tank top cover 3. The top cover 3 is also provided with a biogas outlet 5 . The ratio of the inner diameter of the central inner cylinder 2 to the inner diameter of the reaction tank body 1 is greater than 1:2. The height of the top of the central inner cylinder 2 is hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com