Preparation method and device of hydroxycobalamin salt

A hydroxocobalamin salt and a preparation device technology, which is applied in the field of medicine, can solve the problems of large amount of post-treatment solvent, unfavorable industrialization, macroporous resin residue, etc., and achieve simple reaction product components, shorten production cycle, and reduce pH value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Preparation of Hydroxocobalamin acetate

[0048] Add 90g of methylcobalamin and 6000ml of deionized water to the stirred reaction flask, and after dissolving, use 80wt% glacial acetic acid to adjust the pH of the reaction solution to 2.0-2.8; in a state of stirring, the temperature of the ice-water bath is controlled at 20-30°C, and at 10,000- Under the light of 15000 lux, the pressurized pump was used to ventilate the air for 4-7 hours, and the raw material methylcobalamin was monitored by HPLC to be less than or equal to 0.1%, and the reaction was terminated.

[0049] Slowly add 60000ml of acetone to the above reaction system, stand at -20~-10℃ for crystallization for 16h, filter, wash the filter cake with cold acetone-water mixed solution, and dry at room temperature for about 12h to obtain 81.0g of dark red crystalline solid, yield: 90%.

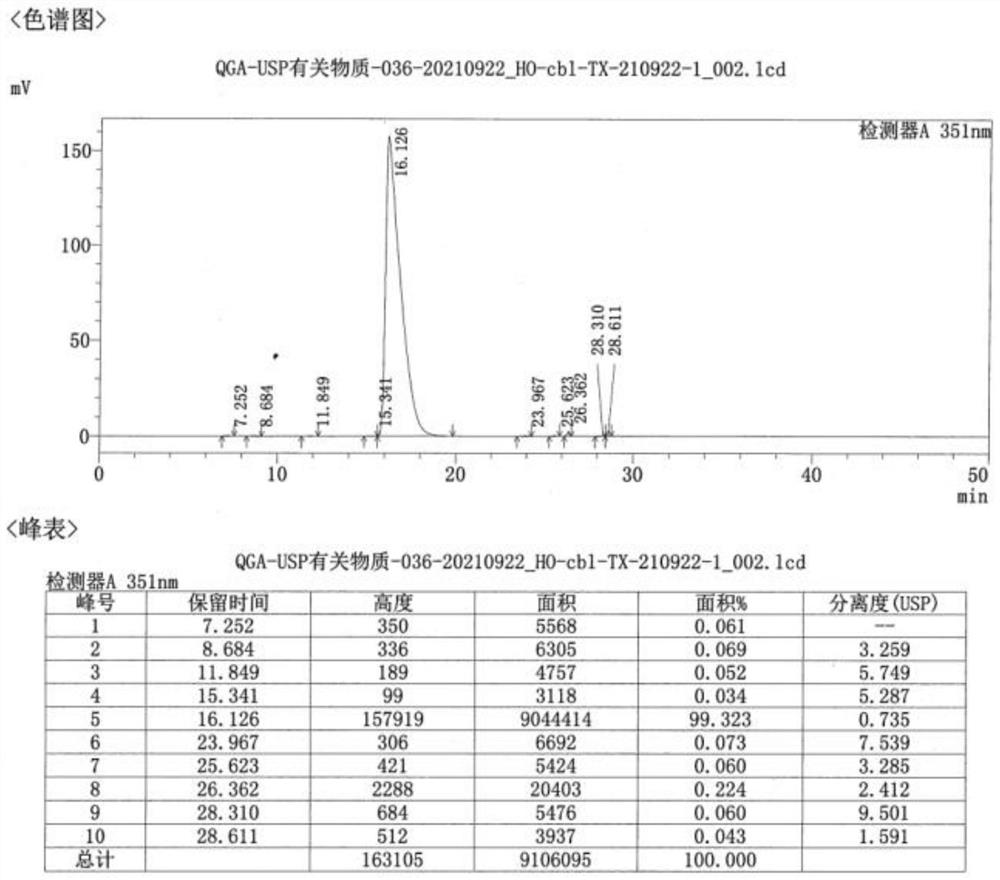

[0050] The HPLC chromatogram was measured, and the test conditions of the HPLC chromatogram were referred to the USP...

Embodiment 2

[0051] Example 2: Preparation of Hydroxocobalamin Sulfate

[0052] Add 120g of methylcobalamin and 6000ml of deionized water to a stirred reaction flask, and after dissolving, use 10wt% sulfuric acid to adjust the pH of the reaction solution to 2.0-2.8; in a stirring state, the temperature of the ice-water bath is controlled at 20-30°C, and the temperature is 10,000-15,000 lux. Under the light, the pressurized pump was used to blow air for 4-7 hours at the same time, and the raw material methylcobalamin was monitored by HPLC to be less than or equal to 0.1%, and the reaction was terminated.

[0053] Slowly add 60000ml of acetone to the above reaction system, stand at -20~-10℃ for crystallization for 16h, filter, wash the filter cake with cold acetone-water mixed solution, and dry at room temperature for about 12h to obtain 110.40g of dark red crystalline solid, yield: 92%.

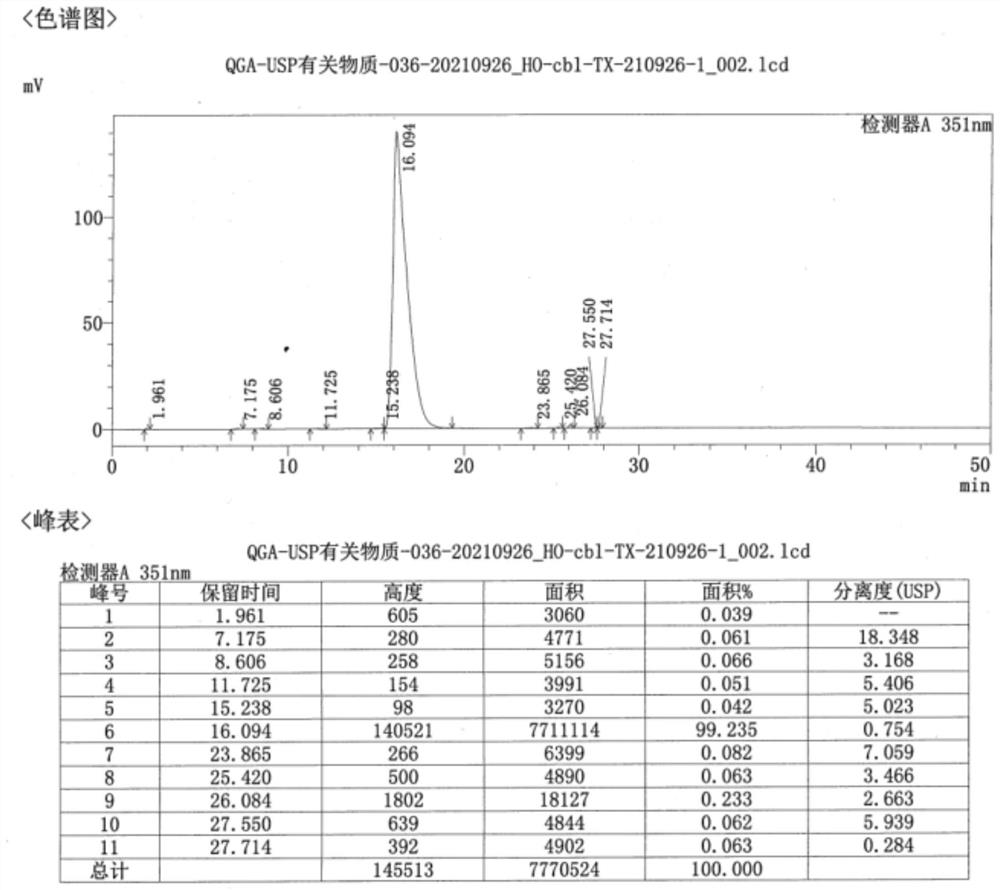

[0054] HPLC chromatogram was measured, and the results are shown in the attached figure 2 , with a p...

Embodiment 3

[0055] Example 3: Preparation of Hydroxocobalamin Hydrochloride

[0056] 180.0g of methylcobalamin and 6000ml of deionized water were added to the stirred reaction flask, and after dissolving, 10wt% hydrochloric acid was used to adjust the pH of the reaction solution to 2.0~2.8. Under the light of 15000 lux, the pressure pump was used to blow air at the same time for about 4 to 7 hours, and the raw material was monitored by HPLC to be less than or equal to 0.1%, and the reaction was terminated.

[0057] Slowly add 60000ml of acetone to the above reaction system, stand at -20~-10°C for crystallization for 16h, filter, wash the filter cake with cold acetone-water mixed solution, and dry at room temperature for about 12h to obtain 167.4g of dark red crystalline solid with a yield of 167.4g. : 93%.

[0058] HPLC chromatogram was measured, and the results are shown in the attached image 3 , with a purity of 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com