Preparation method of biodegradable material based on dual-curing system and application of biodegradable film material of biodegradable material

A biodegradable material and biodegradable film technology, applied in the field of biodegradable film material application and biodegradable material preparation, can solve the problem of incomplete ultraviolet light irradiation of the coating film, achieve excellent stability, avoid separation and uncured, low temperature rapid curing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

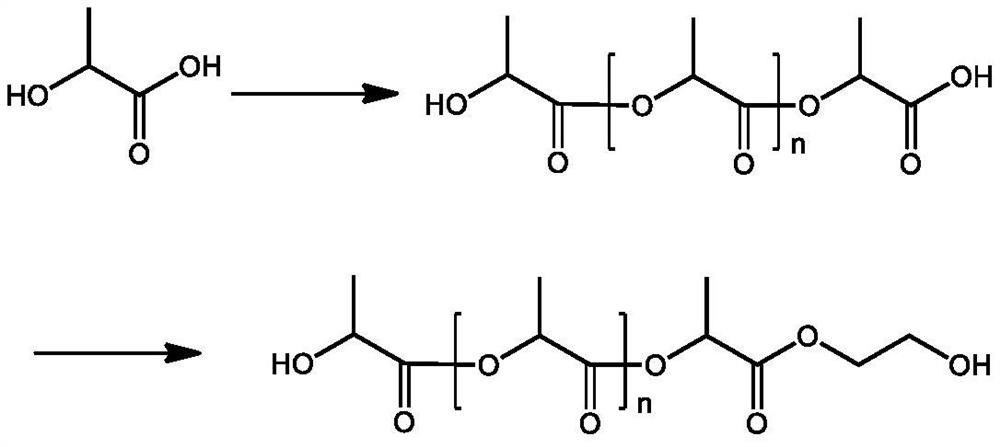

[0047] Firstly, polylactic acid prepolymer was prepared, 30mol lactic acid was added to the reaction kettle, water was removed by vacuuming at 80°C, and the system pressure was controlled to react for 2h under the condition of 35KPa;

[0048] Then add 20mol ethylene glycol and 0.05equiv DCC, heat up to 120°C, control the system pressure at 5KPa, react for 3h, and prepare polylactic acid prepolymer with hydroxyl groups at both ends by melt condensation method.

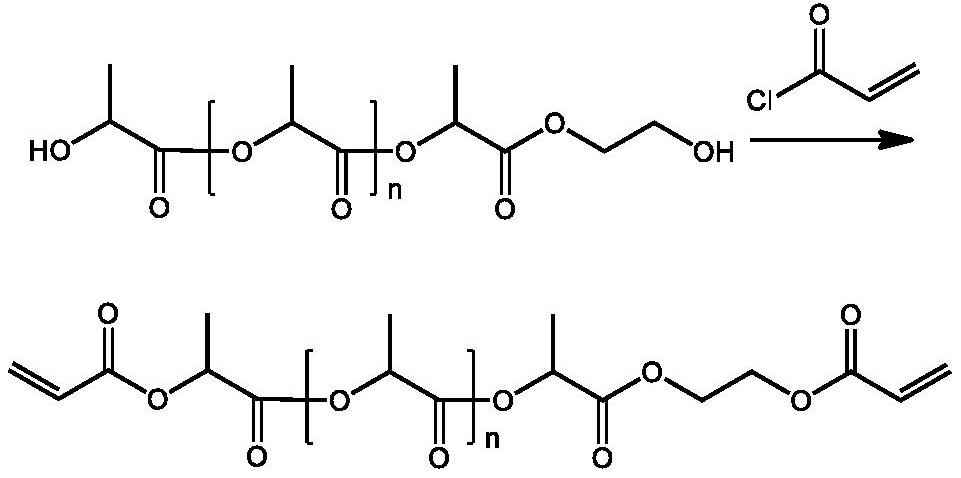

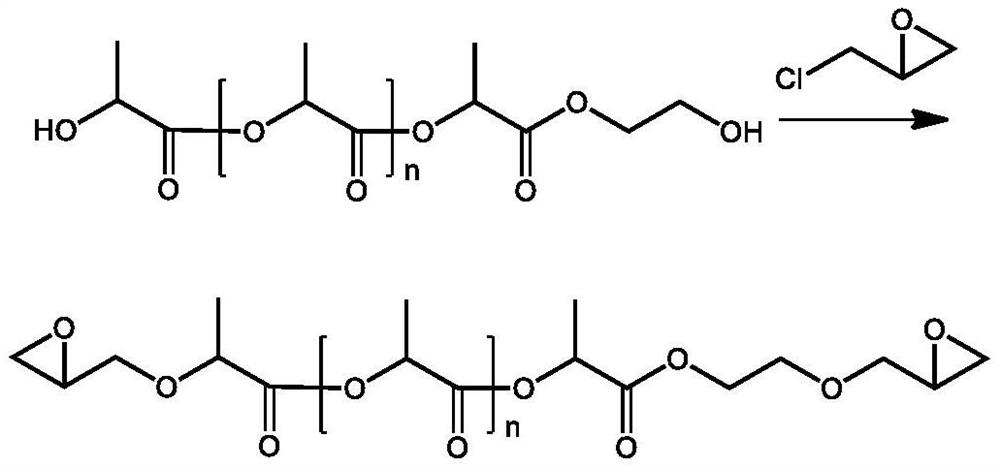

[0049] Next, a resin material was prepared, using the following components: 70 parts of a light-cured polylactic acid prepolymer, 30 parts of a heat-cured polylactic acid prepolymer, 1 part of 2-methyl-1-(4-methylthiophenyl)- 2-Moline-1-propanone, 1 part dimethyl azobisisobutyrate, 0.5 UV absorber.

Embodiment 2-6

[0051]Different from Example 1 are the light-cured polylactic acid prepolymer, heat-cured polylactic acid prepolymer, 2-methyl-1-(4-methylthiophenyl)-2-morpholin-1-propanone, The addition amount of dimethyl azodiisobutyrate and UV absorber is different.

[0052] The specific number of additions is shown in Table 1:

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com