Method for carrying out specific heat test by utilizing synchronous thermal analyzer

A technology of simultaneous thermal analysis and specific heat, applied in the direction of thermal development of materials, etc., can solve the problems of inability to test low temperature or normal temperature phase structure changes, inability to achieve temperature stability at low temperature, DSC curve repeatability, inaccurate measurement results, etc. Short test time, improve repeatability and accuracy, and ensure the effect of low temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

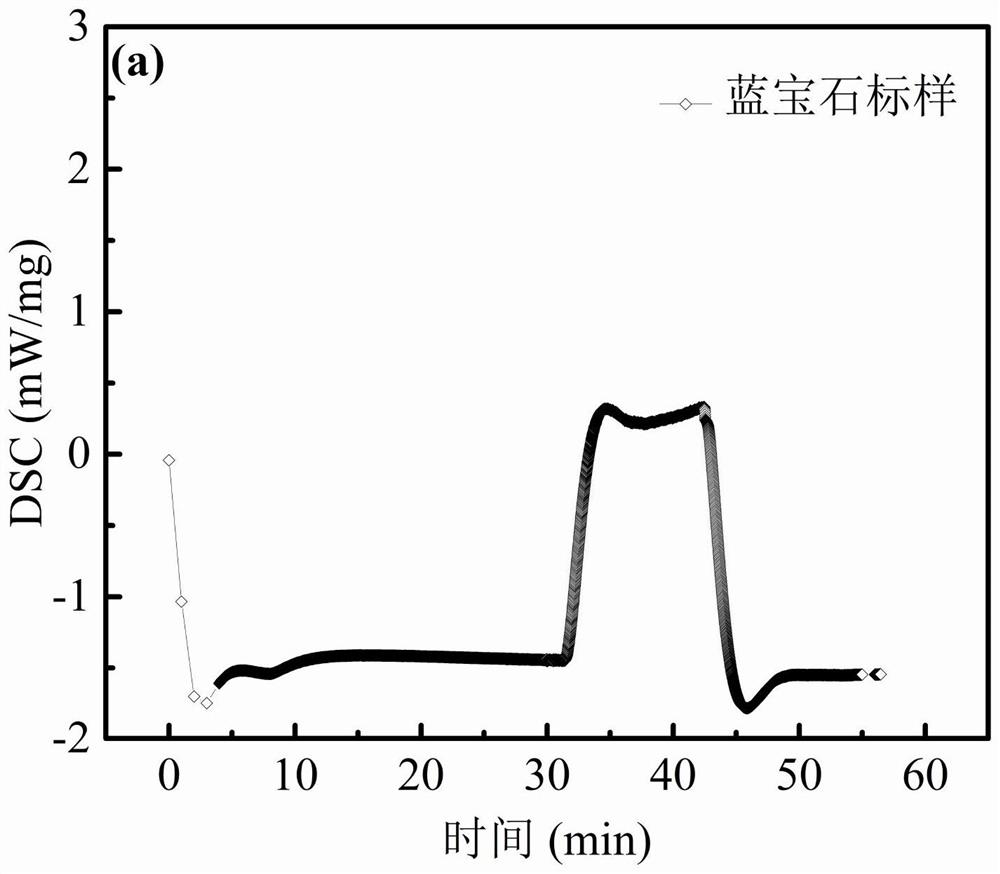

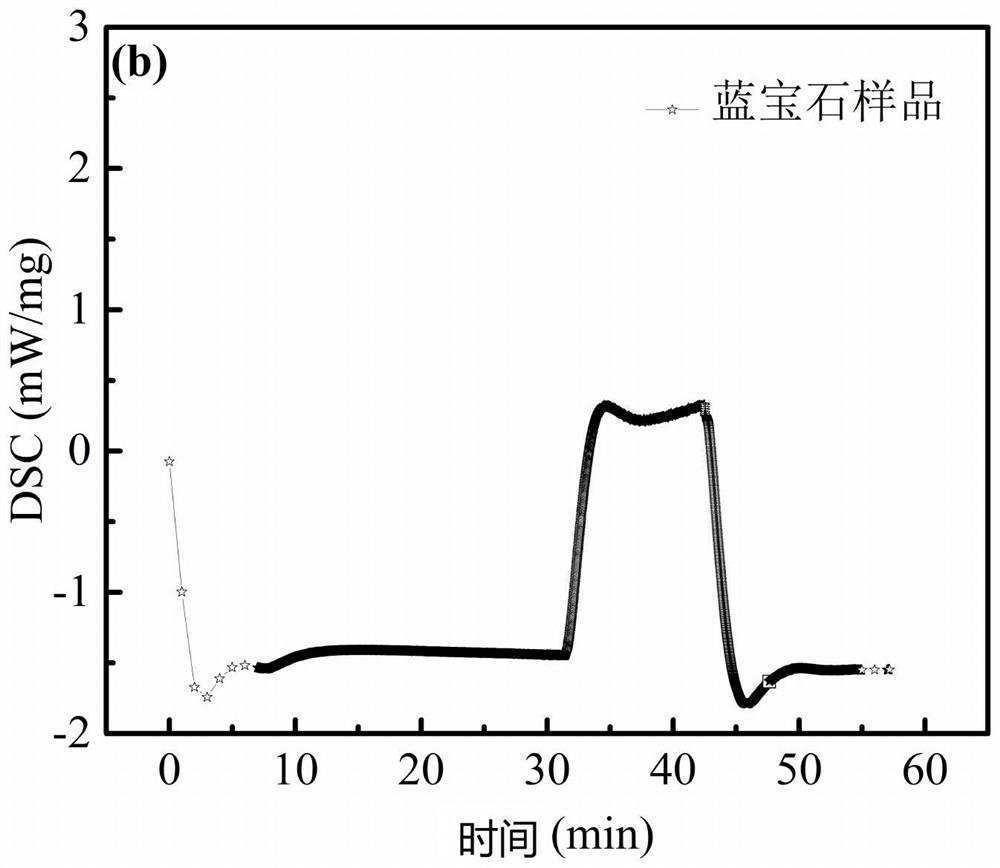

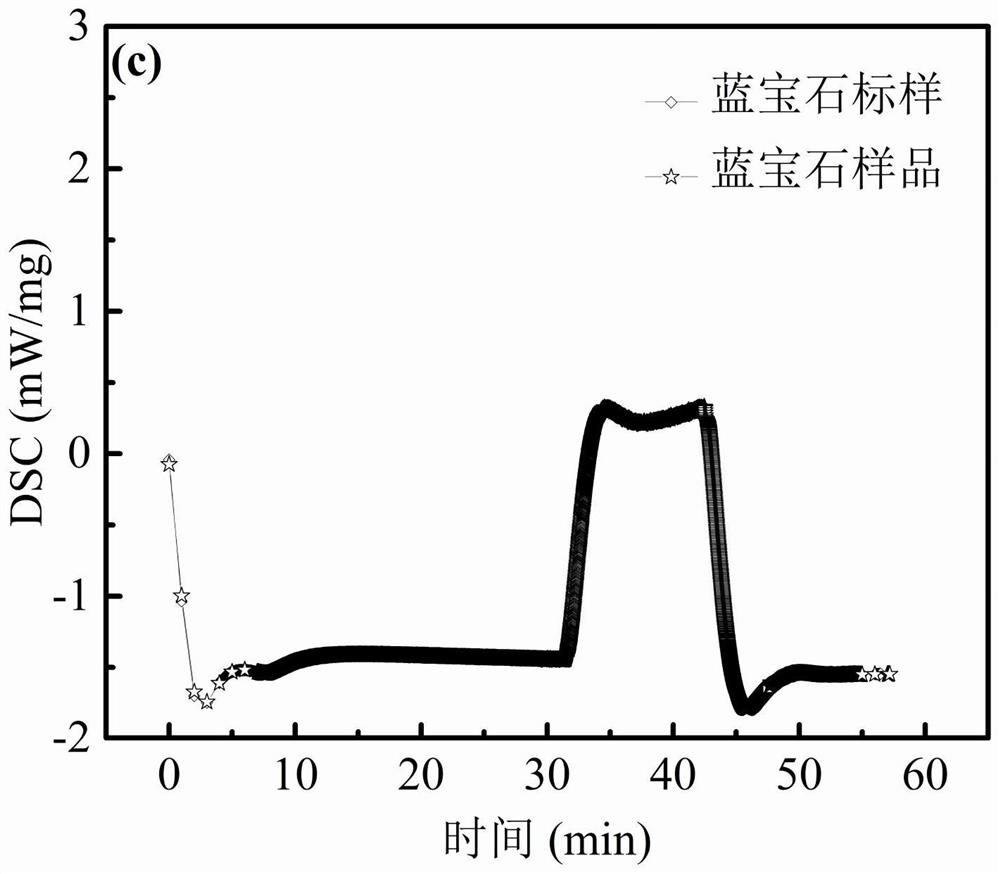

[0058] Example 1: Using a synchronous thermal analyzer, differential scanning calorimetry (DSC) was used to measure the specific heat of sapphire crystal in the temperature range of -10 to 150 ° C. The specific test steps are as follows:

[0059] Step 1: Select the standard sample of sapphire crystal with a diameter of 4mm and a mass of about 12.5mg to clean it, and then place it in the aluminum crucible at the sample end of the sample chamber of the synchronous thermal analyzer;

[0060] Step 2: Evacuate the sample chamber of the synchronous thermal analyzer, and then purify the sample chamber with helium with a purge flow rate of 50ml / min. After the sample chamber returns to normal pressure, use the balance that comes with the synchronous thermal analyzer to accurately Weigh the mass of the sapphire crystal standard;

[0061] Step 3: Open the liquid nitrogen device in advance, first manually cool it to -100°C, set the starting temperature T' of the software program test to -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com