Preparation method of Schiff base crown ether polymer and application of Schiff base crown ether polymer in anion exchange membrane

A Schiff base crown ether and polymer technology, which is used in the synthesis of Schiff base crown ether polymers and the application field of modified polysulfone anion exchange membranes, can solve the problem of poor stability, restricting the development of AEMFC, and low ionic conductivity. and other problems, to achieve the effect of low cost, good application prospects and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

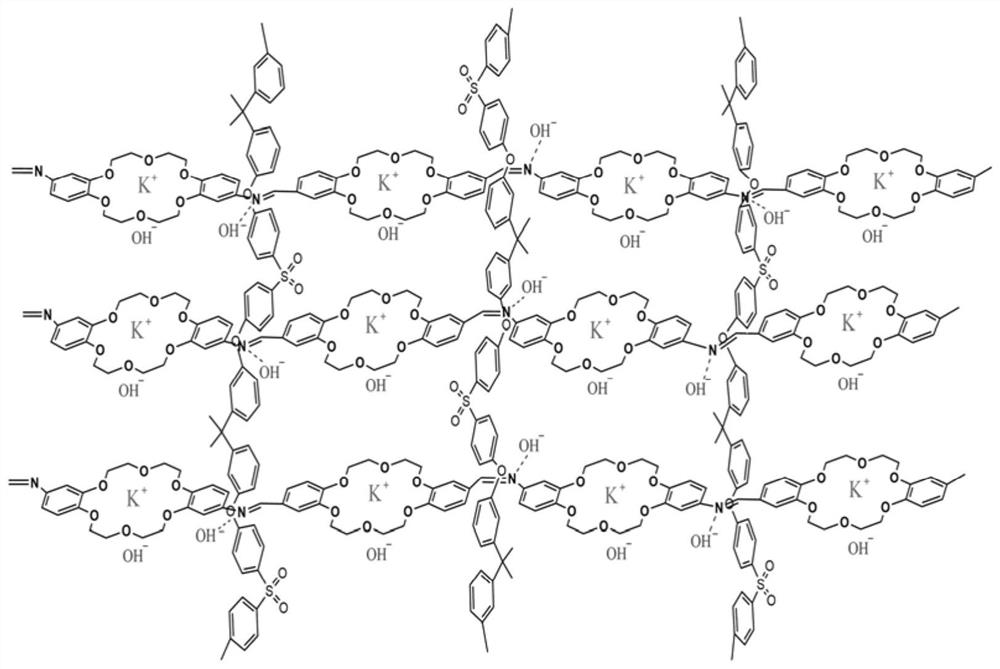

[0034] The preparation method of Schiff base crown ether polymer is implemented according to the following steps:

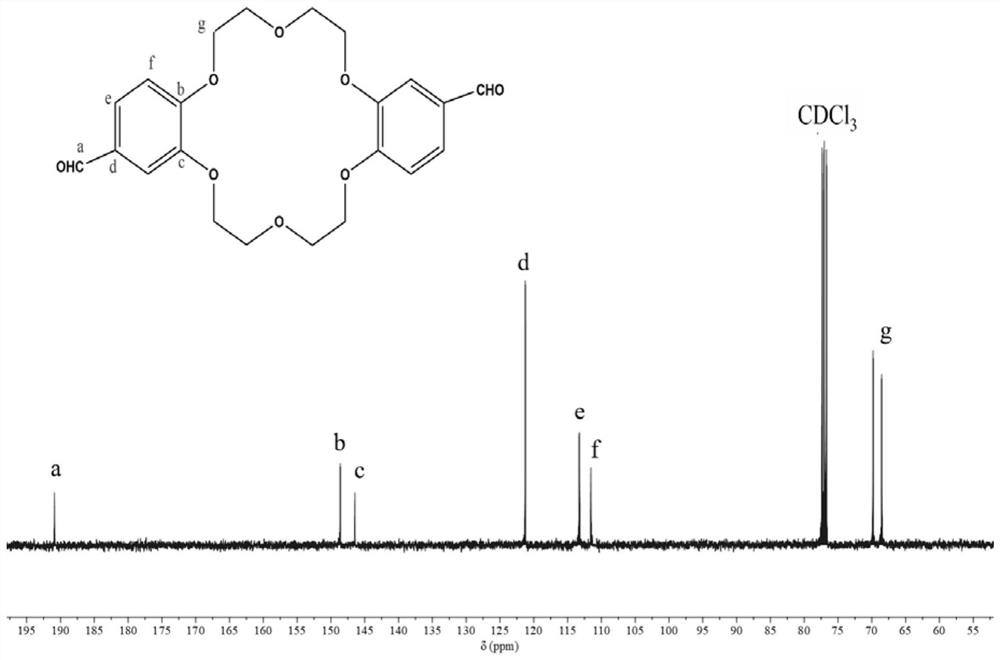

[0035] (1) Weigh 2.016g of dibenzo-18-crown-6 and 3.22g of hexamethylenetetramine into a three-necked flask, add 8.3mL of trifluoroacetic acid, react at 90°C for 12h, cool at room temperature, use benzene Washing gave a brown oily liquid, which was dried over magnesium sulfate to give dialdehyde dibenzo-18-crown-6 (CHOCE).

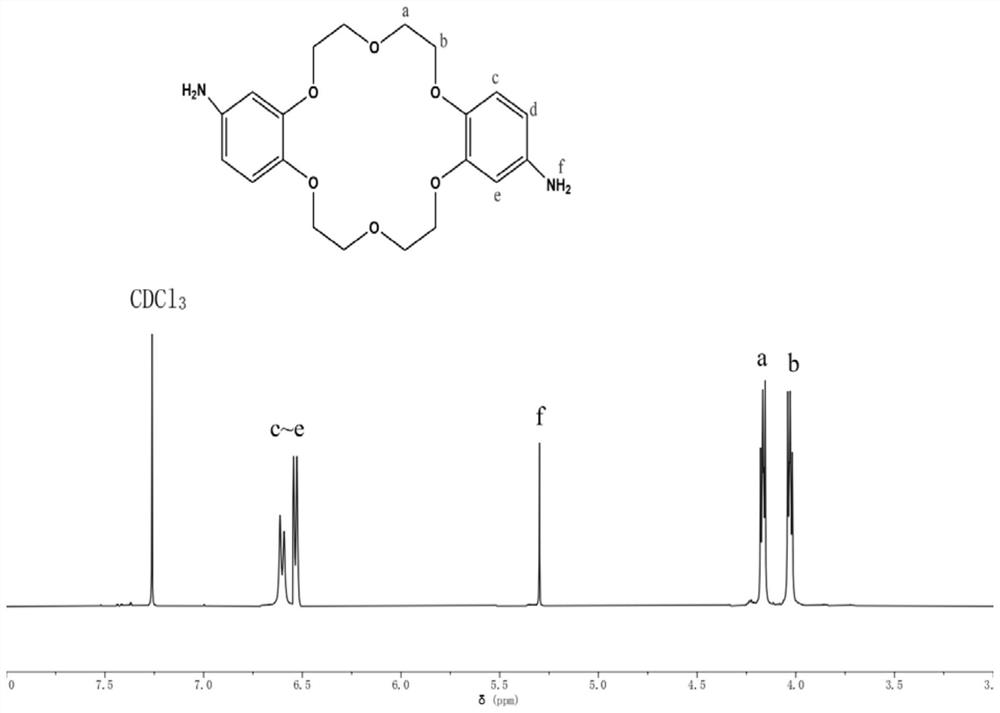

[0036] (2) Weigh 5.0g of dibenzo-18-crown-6 into a three-necked flask, add 100mL of dichloromethane and 75mL of glacial acetic acid, and slowly dropwise add a mixed acid solution of 10mL of glacial acetic acid and 3.5mL of concentrated nitric acid at 50°C, The reaction was carried out for 5 hours, and a large amount of white solid appeared after cooling to room temperature. After filtration, it was washed with ethanol and deionized water, and dried under vacuum at 70 °C for 12 hours to obtain dinitrodibenzo-18-crown-6 (NO 2 CE); then take by...

Embodiment 2

[0040] The preparation method of Schiff base crown ether polymer is implemented according to the following steps:

[0041](1) Weigh 2.016g of dibenzo-18-crown-6 and 3.22g of hexamethylenetetramine into a three-necked flask, add 8.3mL of trifluoroacetic acid, react at 90°C for 12h, cool at room temperature, use benzene Washing gave a brown oily liquid, which was dried over magnesium sulfate to give dialdehyde dibenzo-18-crown-6 (CHOCE).

[0042] (2) Weigh 5.0g of dibenzo-18-crown-6 into a three-necked flask, add 100mL of dichloromethane and 75mL of glacial acetic acid, and slowly dropwise add a mixed acid solution of 10mL of glacial acetic acid and 3.5mL of concentrated nitric acid at 50°C, The reaction was carried out for 5 hours, and a large amount of white solid appeared after cooling to room temperature. After filtration, it was washed with ethanol and deionized water, and dried under vacuum at 70 °C for 12 hours to obtain dinitrodibenzo-18-crown-6 (NO 2 CE); then take by ...

Embodiment 3

[0046] The preparation method of Schiff base crown ether polymer is implemented according to the following steps:

[0047] (1) Weigh 2.016g of dibenzo-18-crown-6 and 3.22g of hexamethylenetetramine into a three-necked flask, add 8.3mL of trifluoroacetic acid, react at 90°C for 12h, cool at room temperature, use benzene Washing gave a brown oily liquid, which was dried over magnesium sulfate to give dialdehyde dibenzo-18-crown-6 (CHOCE).

[0048] (2) Weigh 5.0g of dibenzo-18-crown-6 into a three-necked flask, add 100mL of dichloromethane and 75mL of glacial acetic acid, and slowly dropwise add a mixed acid solution of 10mL of glacial acetic acid and 3.5mL of concentrated nitric acid at 50°C, The reaction was carried out for 5 hours, and a large amount of white solid appeared after cooling to room temperature. After filtration, it was washed with ethanol and deionized water, and dried under vacuum at 70 °C for 12 hours to obtain dinitrodibenzo-18-crown-6 (NO 2 CE); then take by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com