Anti-reflective PVC (polyvinyl chloride) composite film for medicine packaging and preparation method of anti-reflective PVC composite film

A packaging, anti-reflection technology, applied in packaging recycling, sustainable packaging industry, sustainable manufacturing/processing, etc., can solve the problems of false detection and missed detection, high labor cost, reflection, etc. Reflection problem, effect of excellent performance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An anti-reflective PVC composite film for pharmaceutical packaging, comprising the following components by weight: 100 parts of PVC resin powder, 20 parts of MBS resin (model BTA730), and 5 parts of a copolymer of methyl methacrylate and alkyl acrylate ( Model P-551J), 5 parts of octyl tin thiol, 0.4 part of lubricant.

[0026] The preparation method of the above-mentioned anti-reflection PVC composite film for pharmaceutical packaging comprises the following steps:

[0027] 1) Heat the PVC resin powder and MBS resin to 70°C with stirring, then add 1-2 parts of water-soluble epoxy resin, stir and heat to 85°C, add octyl tin thiol, polyethylene wax, methyl methacrylate and acrylic acid Alkyl ester copolymer, heated to 100 ℃ to dissolve;

[0028] 2) Take out of the pot, put it into a cold pot, quench it at 30-40°C, sieve it, and start the training machine to squeeze out air bubbles;

[0029] 3) The material is processed in turn by a calender, and five rolls are used for...

Embodiment 2

[0037] The preparation method of the anti-reflective PVC composite film for pharmaceutical packaging is the same as that in Example 1, wherein the composition of the composite film is shown in Table 1.

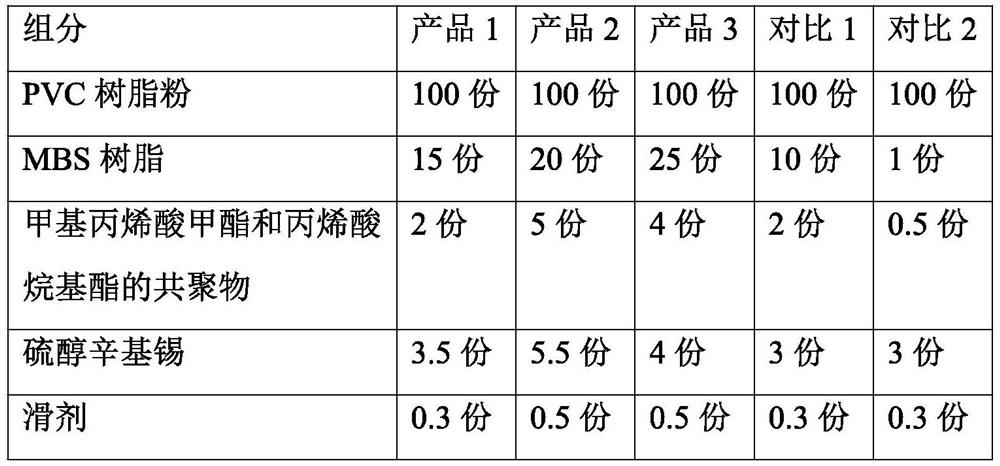

[0038] Table 1 Composition of composite membranes

[0039]

[0040] Among them, the commercial model of MBS resin used in product 1 is BTA730, product 2 is BTA707, product 3 is B-513, and comparison 1 is BTA730. The copolymer of methyl methacrylate and alkyl acrylate used in product 1 is commercially available P530A, product 2 is PA-20, product 3 is P-551J, and contrast 2 is P-551J; the lubricant used in product 1 The commercially available model is 316A, product 2 is polyethylene wax, and product 3, comparison 1 and comparison 2 are high-density oxidized polyethylene wax.

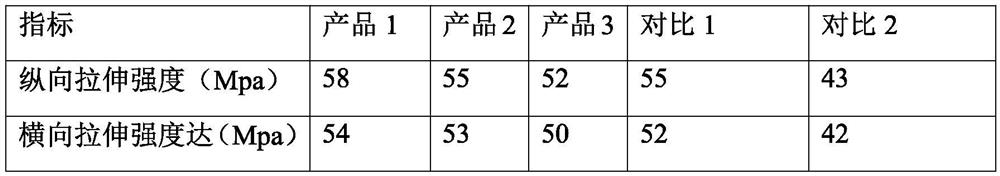

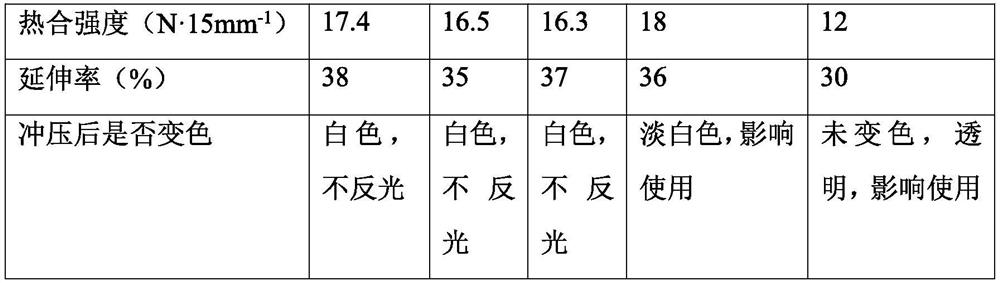

[0041] The prepared products were tested for performance, and the specific results are shown in Table 2.

[0042] Table 2 Mechanical properties of products

[0043]

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal tensile strength | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com