Biomimetic polymer filtrate reducer for drilling fluid

A technology of fluid loss reducer and polymer, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., to achieve the effects of improving temperature and salt resistance, low permeability, and improving water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

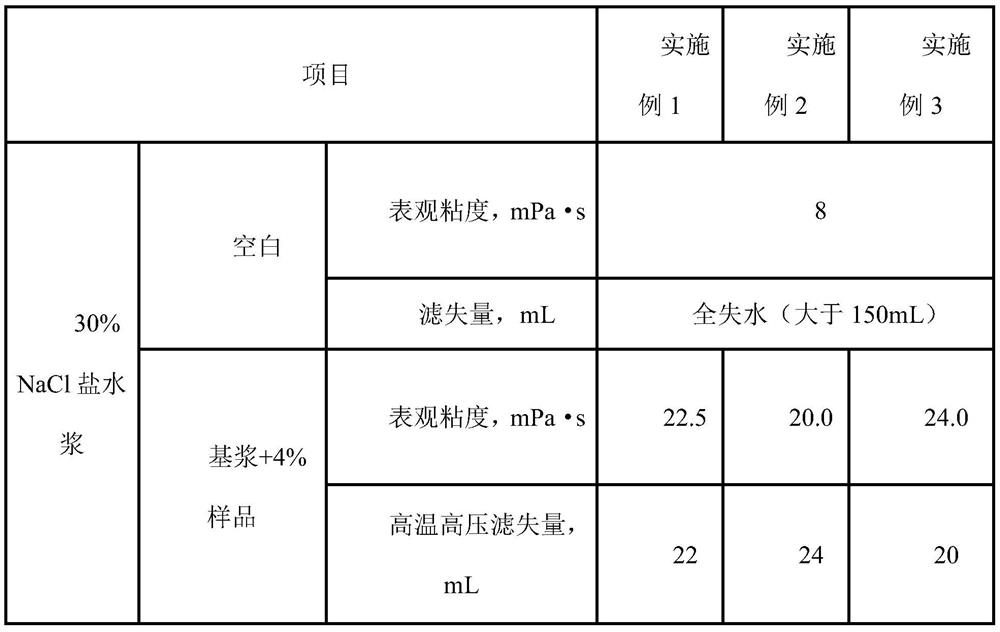

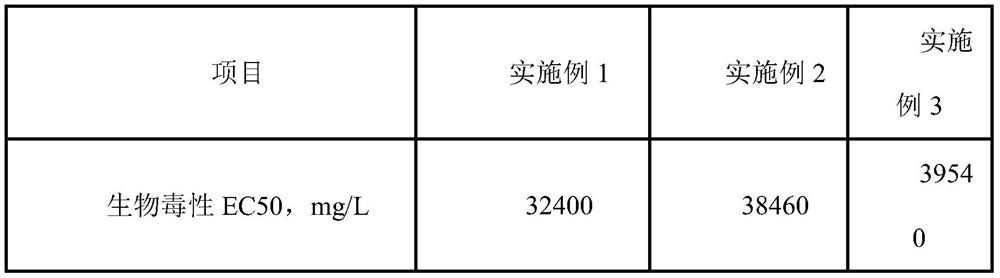

Examples

Embodiment 1

[0026] In the embodiment of the present invention, a biomimetic polymer fluid loss reducer for drilling fluid, the fluid loss reducer is composed of raw materials in the following proportions by weight:

[0027] Modified lignin 400-500g, 20% NaOH solution 260-300g, 60% sodium hydroxymethanesulfonate solution 400-800g, polyaziridine 100-180g, defoamer 0.5g-1.51g.

[0028] It is composed of raw materials in the following proportions by weight: 450 g of modified lignin, 280 g of 20% NaOH solution, 600 g of 60% sodium hydroxymethanesulfonate solution, 150 g of polyaziridine, and 1 g of defoaming agent.

[0029] Among them, the defoamer is emulsified silicone oil.

[0030] It can be prepared by modifying the modified lignin, wherein, the raw materials in the proportion by weight are composed as follows,

[0031] 1-3L 1% NaOH solution, brown rot lignin 40-120g, 0.22-0.66g NaBH4, 2mol / L hydrochloric acid solution.

[0032] The ratio of modified lignin is modified: 4.2L 1% NaOH solu...

Embodiment 2

[0039] 450g of modified lignin, 280g of 20% NaOH solution, 160g of 60% sodium hydroxymethane sulfonate solution were added to a four-necked flask containing 500 mL of distilled water, heated and refluxed for 1 hour, and then 60% of sodium hydroxymethane sulfonate was added. 160g of solution, refluxed for 1.5h, added defoamer, then added 100g of distilled water and 120g of polyaziridine, mixed and refluxed for about 50min, then added 100g of distilled water and 160g of 60% sodium hydroxymethanesulfonate solution, reacted for half an hour, That is, the final product fluid loss reducer is obtained.

Embodiment 3

[0041] 450g of modified lignin, 280g of 20% NaOH solution, 200g of 60% sodium hydroxymethane sulfonate solution were added to a four-necked flask containing 500 mL of distilled water, heated and refluxed for 1 hour, and then 60% of sodium hydroxymethane sulfonate was added. 200g of the solution, refluxed for 1.5h, added antifoaming agent, then added 100g of distilled water and 150g of polyaziridine, mixed and refluxed for about 50min, then added 100g of distilled water and 200g of 60% sodium hydroxymethanesulfonate solution, reacted for half an hour, That is, the final product fluid loss reducer is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com