Carbon nano super-hydrophobic water-based paint and preparation method thereof

A water-based coating, super-hydrophobic technology, applied in the direction of polyurea/polyurethane coatings, coatings, climate sustainability, etc., can solve problems such as being unsuitable for industrial production and application, increasing coating roughness, and limited super-hydrophobic effect. To achieve the effect of improving hydrophobic performance, increasing roughness, and increasing hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

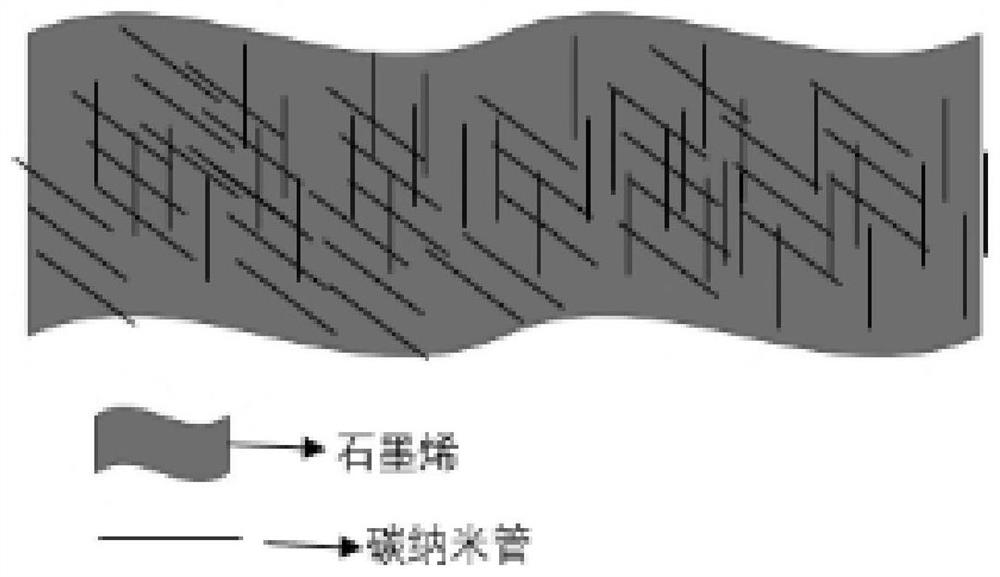

[0033] GNS / NH 2 -The preparation method of MWCNT is:

[0034] S1. Add a certain amount of silane coupling agent with amino group and polyvinylamine into a certain amount of ethanol, stir and disperse evenly to obtain a dispersion;

[0035] S2, adding the above-mentioned dispersion liquid to a certain amount of carboxylated multi-walled carbon nanotubes by spraying, heating and stirring at 80°C, and the reaction time is 5-10min to obtain amino-modified carbon nanotubes;

[0036] S3. Add a certain amount of amino-modified carbon nanotubes to a certain concentration of graphene oxide dispersion, and react at 60-80 °C for 1-2 hours to obtain GO / NH 2 -MWCNT;

[0037] S4. Add a certain amount of HI and continue the reaction at 80°C for 0.5-1h to obtain GNS / NH 2 - complexes of MWCNTs.

[0038] The mass fraction of the amino group-bearing silane coupling agent and polyvinylamine in ethanol is 0.4%-1%, and the mixing speed is 10-50r / min.

[0039] The diameter of the amino-modified...

Embodiment 1

[0046] 1. Preparation of GNS / NH 2 -MWCNT:

[0047] S1. Add 0.4%-1% silane coupling agent with amino group and polyvinylamine into a certain amount of ethanol, and the mixing speed is 10-50r / min, and the dispersion is uniformly obtained by stirring and dispersing;

[0048] S2, adding the above-mentioned dispersion liquid to a certain amount of carboxylated multi-walled carbon nanotubes by spraying, heating and stirring at 80°C, and the reaction time is 5-10min to obtain amino-modified carbon nanotubes;

[0049] S3. Add amino-modified carbon nanotubes with a mass concentration of 0.5-2% into a graphene oxide dispersion with a concentration of 0.5%-2%, and react at 60-80 ° C for 1-2 hours to obtain GO / NH 2 -MWCNT;

[0050]

[0051] S4. Add 0.5%-5% HI by mass, and continue the reaction at 80°C for 0.5-1h to obtain GNS / NH 2 - complexes of MWCNTs.

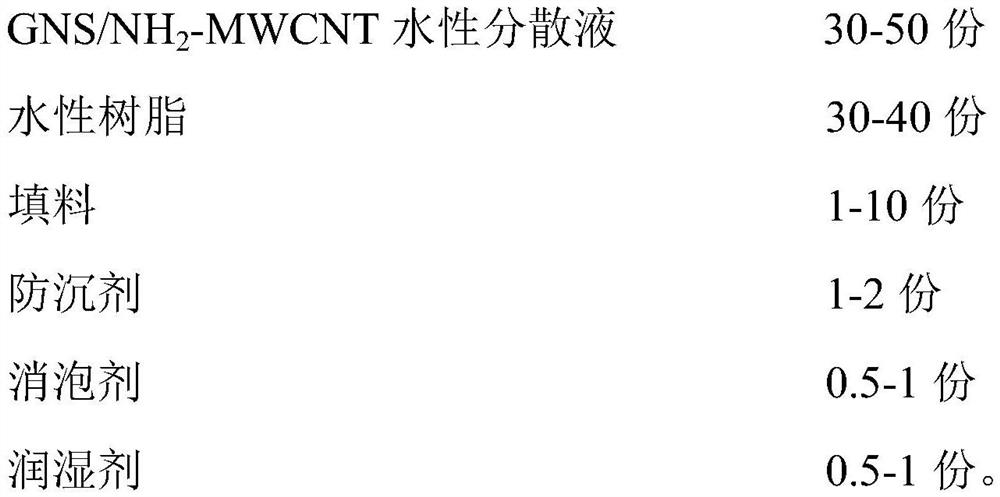

[0052] 2. Preparation of paint:

[0053] Take the above GNS / NH 2 -MWCNT to prepare GNS / NH 2 -MWCNT aqueous dispersion, take GNS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com