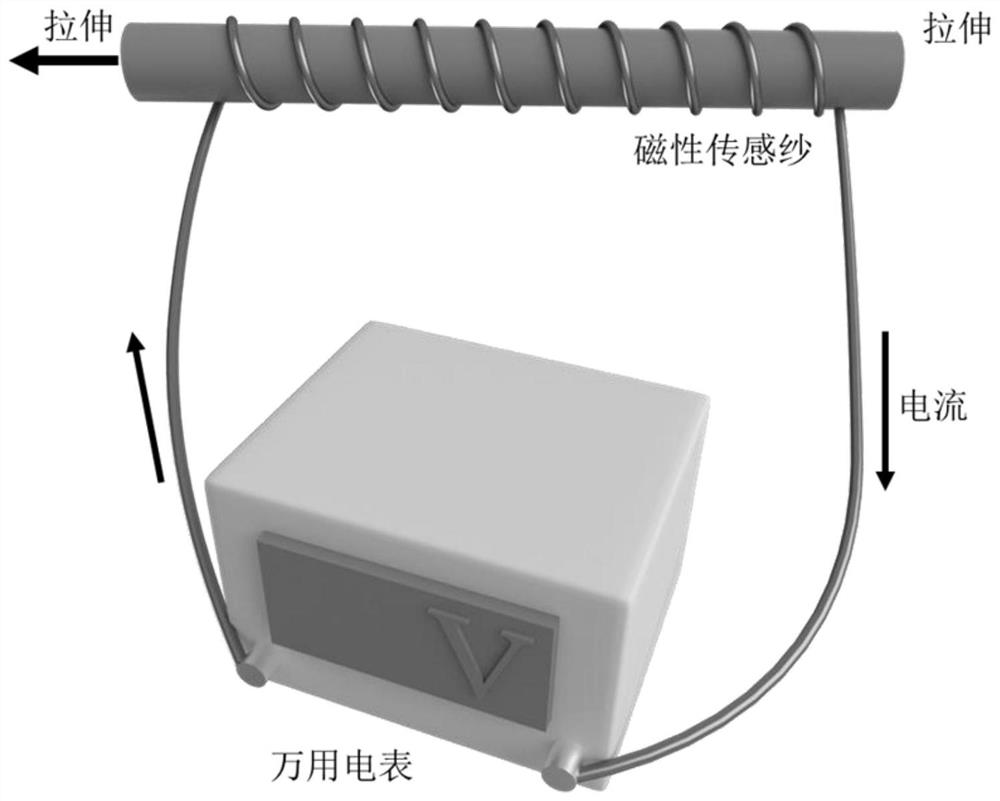

Magnetic particle elastic linear material as well as preparation method and application thereof

A technology of magnetic particles and elastic threads, applied in the field of functional materials and textile processing, can solve the problems of small changes in magnetic flux, the yarn body does not have high elastic ability, weak electromagnetic induction signals, etc., and achieves flexible and extensive application scenarios, convenient methods and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

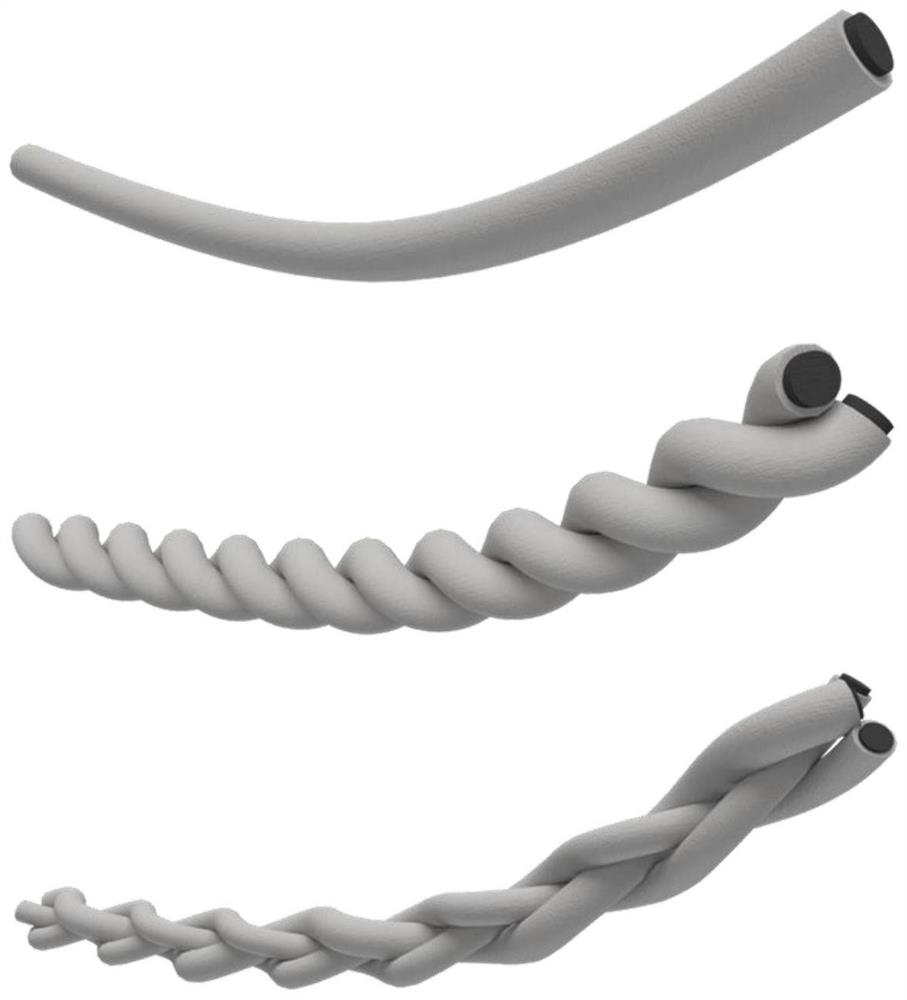

[0049] The preparation method further includes: weaving the elastic linear material of the magnetic particle body obtained in step S2 to obtain an elastic magnetic particle wire or an elastic magnetic particle rope.

[0050] Specifically, taking the polyurethane (TPU) film as an example, a preparation method of the elastic magnetic grain yarn is:

[0051] (1) Cut the translucent TPU film with a thickness of 0.02mm into strips with a width of 25mm, and feed the micron-level magnetic powder into a fixed-volume slot-shaped 3D printing mold;

[0052] (2) Upside down the mold containing the magnetic powder on the TPU film to achieve the purpose of feeding the magnetic powder material uniformly and quantitatively, and then fold the TPU film in half to wrap the magnetic particles and form a new package;

[0053] (4) Feed the TPU strip package wrapped with magnetic powder into the front roller of the roving frame for twisting into yarn, the rotating speed of the roving frame is 300r / m...

Embodiment 1

[0058] see Figure 11 As shown in the figure, a preparation process of the elastic linear material of the magnetic particle body specifically includes the following steps:

[0059] Step 101, preparation of elastic non-woven fabric strip (film).

[0060] The industrially produced surface materials such as elastic non-woven fabrics (films) are cut into elastic strips with a linear density of 5-1000 g / km by a cutting machine, and each strip is wound on a bobbin to form an elastic strip. Comes with bobbins.

[0061] Step 102, wrapping the magnetic particles in an elastic non-woven strip (film) to prepare a magnetic material pre-packaged aggregate.

[0062] Specifically, the micro-nano magnetic particle material with a particle size ranging from 0.05 μm to 500 μm is placed into the elastic non-woven fabric strip (film) cut by the cutting machine provided in step 101, and the micro-nano magnetic particle material is used. The mass percentage of the prepackage aggregate is formed ...

Embodiment 2

[0071] see Figures 5 to 9 As shown, an elastic magnetic particle slub yarn is prepared by the following steps:

[0072] (1) Cut the translucent TPU film with a thickness of 0.02mm into strips with a width of 25mm, and feed the micron-level magnetic powder into a fixed-volume slot-shaped 3D printing mold;

[0073] (2) Upside down the mold containing the magnetic powder on the TPU film to achieve the purpose of feeding the magnetic powder material uniformly and quantitatively, and then fold the TPU film in half to wrap the magnetic particles and form a new package;

[0074](4) Feed the TPU strip package wrapped with magnetic powder into the front roller of the roving frame for twisting into yarn, the rotating speed of the roving frame is 300r / min, the twist is set to 49T / m, and the fineness is 30~3000tex Polyurethane Magnetic Grain Yarn.

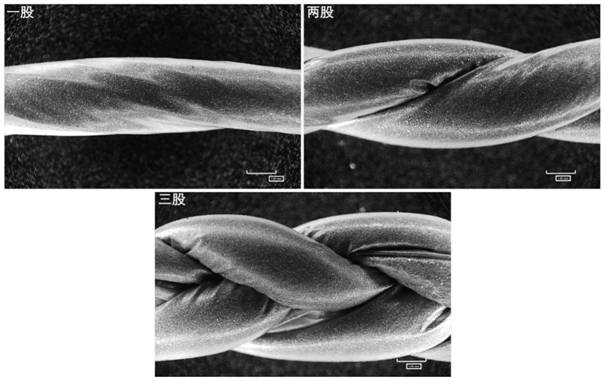

[0075] The polyurethane magnetic particle yarn is twisted or braided to obtain multi-strand polyurethane magnetic particle wires or ropes....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com